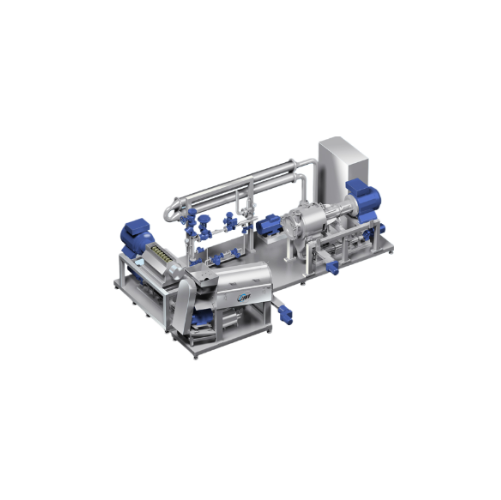

Industrial extraction line for fruits and vegetables

Optimize your fruit and vegetable processing with a highly flexible extraction line, capable of seamlessly switching between hot and cold processes to deliver superior juice, puree, and smoothie products with minimized oxidation and enhanced flavor retention.

Processes Fruits and Vegetables into Juices and Purees

The READYGo™ Extraction System from JBT is tailored for fruit and vegetable processors aiming for streamlined juice and puree production. This system stands out with its dual hot and cold extraction capabilities, allowing for exceptional process flexibility. Designed to handle up to 6 tons per hour, it efficiently processes a wide range of products into cloudy juices, smoothies, or purees. The pre-engineered, plug-and-play setup ensures easy integration and rapid changeovers, minimizing downtime. Its compact design reduces the installation footprint and simplifies utility requirements. Featuring minimized oxidation through reduced transfer time, it also supports aseptic packaging and HPP treatment, catering to food safety standards. Constructed with durable materials for robustness and easy maintenance, the system is well-suited for juice manufacturers and smoothie producers seeking high-quality results with minimal operational complexity.

Benefits

- Enhances product versatility by accommodating both hot and cold extraction techniques.

- Streamlines production with rapid changeovers, minimizing operational delays.

- Lowers installation costs due to compact, pre-assembled design.

- Protects product quality with minimal oxidation during processing.

- Facilitates seamless integration into existing lines, boosting overall production efficiency.

- Applications

- Smoothies, Cloudy juice, Tomato processing, Fruits, Vegetables, Purees, Juices

- End products

- Spinach-kale smoothie, Mixed berry smoothie, Lemon cloudy juice, Apple juice, Orange juice, Mango puree, Carrot juice, Tomato paste, Grape puree, Lime cloudy juice

- Steps before

- Destalking, Sorting, Washing

- Steps after

- Freezing, Aseptic Packing, HPP Treatment

- Input ingredients

- sound and ripe fruits, sound and ripe vegetables, destalked fruits, destalked vegetables, sorted fruits, sorted vegetables, washed fruits, washed vegetables

- Output ingredients

- single strength cloudy juice, smoothies, puree with enzymes inactivated

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- Up to 6 t/h

- Extraction Type

- Hot/Cold extraction

- Output

- Single strength cloudy juice, smoothies, puree

- Oxidation

- Low product oxidation

- Configuration

- Pre-engineered and pre-assembled

- Integration

- Easy to integrate in an existing line

- Transport

- Easy to transport and ground level configuration

- Product Changeover

- Quick

- Process configuration

- Hot/Cold extraction selectable

- Product flexibility

- Wide range of product applications

- Extraction type

- Continuous single strength

- Oxidation control

- Low product oxidation

- Changeover efficiency

- Quick product change over

- Cleanability

- High

- Corrosive resistance

- Excellent

- Machine Footprint

- Compact, limited footprint

- Feed Discharge Method

- Ground level configuration

- Transportability

- Easy to transport

- Control panel type

- PLC-controlled

- Process configuration

- Hot/Cold extraction selectable

- Integration possibilities

- Easy to integrate in existing line

- Footprint size

- Compact, ground level configuration

- Transportability

- Easy to transport