Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures precise heating, cooling, and pasteurization, substantially reducing energy costs while maintaining product quality.

Heats, Cools, and Pasteurizes Beverages and Liquid Products

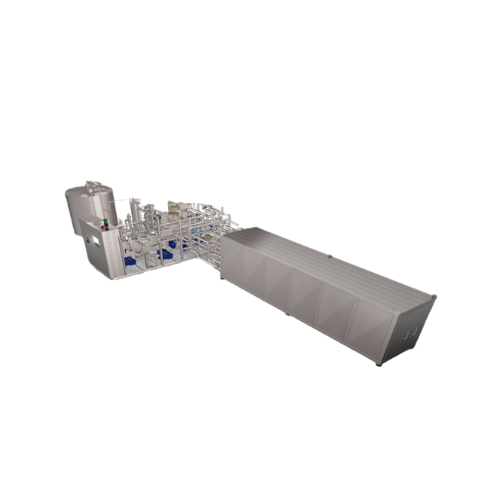

The Innopro HF Pasteurization and Heating System from KHS Group offers a robust solution for efficiently heating, cooling, and pasteurizing various beverages and liquid foods. Utilizing tubular and plate heat exchangers, it adeptly manages low- and high-viscosity products, handling up to 45,000 liters per hour. Designed for continuous, high-speed operations, it serves beverage manufacturers, food producers, and the dairy industry, facilitating processes from juice deaeration to lactose-free milk treatment. The system features warm product deaeration with flavor recovery, significantly reducing residual oxygen content. With energy-efficient heat recovery technology, it integrates seamlessly into your energy management system, allowing energy savings of up to 50%. Automation is supported by a PLC control system, ensuring precision. The unit is constructed from corrosion-resistant materials, maintaining product quality and durability. With optional configurations and engineering support, this equipment meets diverse production needs while optimizing resource use.

Benefits

- Enhances energy efficiency, achieving up to 50% heat recovery.

- Optimizes product quality with reduced residual oxygen levels.

- Accommodates a wide range of product viscosities for versatile application.

- Minimizes operational costs with high throughput capacity.

- Seamlessly integrates into existing production lines for streamlined processing.

- Applications

- Food, Beverages, Liquid food, Wine, Milk, Nonfood, Iced tea, Spirits, Still water, Homecare products, Juice, Soft drinks, Beer, Sparkling wine

- End products

- Fruit juice concentrates, Sauces, Sparkling rosé wine, Liquid detergents, Green tea iced tea, Red wine, Vodka, Lactose-free milk, Cleaning solutions, Carbonated soft drinks, Filtered water, Flavored water

- Steps before

- Purification, Grinding, Blending, Ingredient Mixing, Heating Preparation

- Steps after

- Cooling, Filling, Packing, Pasteurization, Labeling

- Input ingredients

- non-carbonated beverages, low-viscosity beverages, high-viscosity products, products with high fiber content, products with high pulp content

- Output ingredients

- hot-filled beverages, pasteurized products, low residual oxygen beverages, energy-efficient filled products

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Capacity

- Up to 45, 000 liters/hour

- Throughput capacity

- Up to 45, 000 liters/hour

- Operating Costs

- Extremely low

- Energy Savings

- Up to 50%

- Heat Recovery

- Maximum

- Automation

- Process automation available

- Residual Oxygen Content Reduction

- Impressively low

- Product Temperature Control

- Specific to product

- Working mechanism

- Innopro HF Pasteurization and Heating System

- Integrated steps

- Heating, Cooling, Deaeration

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Energy savings up to 50%

- Automation level

- PLC-controlled

- CIP/SIP

- CIP compatible

- Cooling system

- Recirculating chiller

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- PET / Glass

- Container size

- Varied

- Machine Sections

- Heater, trim cooler, recirculating chiller

- Heat Exchangers

- Plate or tubular

- Warm Product Deaeration

- Optional with flavor recovery

- Control panel type

- PLC / HMI interface

- Integration possibilities

- Process automation / data interface

- System planning

- Turnkey solutions

- Heating system options

- Plate / Tubular heat exchangers

- Syrup room integration

- Yes

- Packaging line integration

- Turnkey integration

- Energy management integration

- Yes

- Flavor recovery system

- Optional