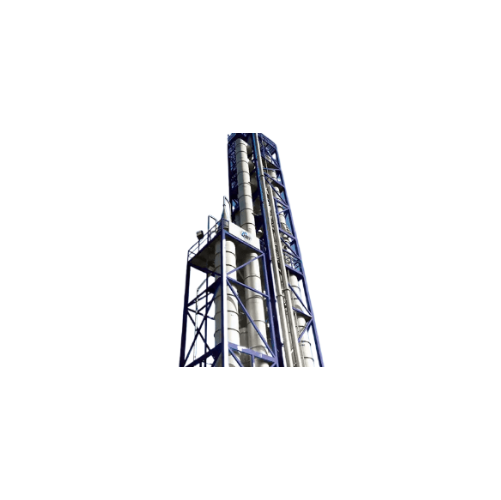

Hybrid evaporator for highly viscous tomato concentrate

Achieve superior concentration and energy efficiency with a versatile evaporator designed for high-viscosity materials, providing optimal recirculation and separation to enhance product quality and reduce thermal damage in your processing line.

Concentrates and Recirculates Liquids and Slurries

The JBT Hybrid Evaporator from JBT FoodTech merges the strengths of Forced Circulation Evaporators with the T.A.S.T.E. system for efficient liquid and slurry concentration. By leveraging upward forced flow recirculation in vertical tube-in-shell heaters, it ensures optimal processing of diverse products like coffee concentrates, nut oils, and tomato paste. Designed for continuous operation, it significantly reduces energy consumption and minimizes thermal damage to maintain the highest quality output. The system features special inducers for high efficiency at low NPSH, preventing cavitation. Capable of handling a range of liquid and slurry types common in the food and beverage industry, it integrates seamlessly into production lines with automated controls and reduced maintenance requirements. Custom configurations are available to meet specific processing needs.

Benefits

- Lowers operational costs by reducing energy consumption.

- Enhances product quality through minimized thermal damage.

- Prevents cavitation with high efficiency at low NPSH.

- Decreases maintenance time with streamlined cleaning procedures.

- Adapts to varied processing needs with customizable configurations.

- Applications

- Beverages, Coffee, Fruits, Nuts, Juices, Tea

- End products

- Coffee concentrates, Fruit purees, Herbal tea concentrates, Vegetable concentrates, Tea extracts, Nut oils, Tomato paste, Orange juice concentrate, Apple juice concentrate, Almond milk base

- Steps before

- Grinding, Mixing, Fruit, Vegetable Processing, Citrus Processing, Tomato Processing, Preparation

- Steps after

- Sterilization, Filling, Closing, Packing, Product Labeling, Food Safety, Postharvest Processing

- Input ingredients

- super-hot break products, highly viscous products, tomato concentrate

- Output ingredients

- high-quality viscous products, improved organoleptic properties

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Energy Consumption

- Reduced

- Cleaning Method

- Fast to clean

- Maintenance

- Low

- Viscous Product Handling

- High efficiency

- Thermal Damage Reduction

- Reduced holding times

- NPSH Requirement

- Very low

- Automation Level

- Manual/Auto

- Recirculation System

- Upward forced flow

- Working mechanism

- Upward forced flow recirculation

- Flow type

- Multiple effect evaporators

- CIP/SIP

- Fast to clean

- Batch vs. continuous operation

- Forced Circulation / T.A.S.T.E. Evaporator

- Energy efficiency

- Reduced energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- High

- Heat sensitivity

- Yes

- Liquid vapor separation

- Required

- Container size

- Varies

- Machine footprint

- Compact or standard

- Configuration

- Multiple effect evaporators

- Tube style

- Vertical tube in shell heater

- Flow configuration

- Upward forced flow recirculation

- Recirculation pump

- Included

- Control panel type

- PLC/SCADA integration

- Integration possibilities

- Upward forced flow recirculation

- Material Customization

- High viscosity product compatibility

- Inducer type

- High efficiency at low NPSH