Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchanger, specifically designed to reduce thermal impact, optimize energy efficiency, and handle a diverse range of products, including those containing particles or fibers, all while safeguarding the integrity of flavor and nutrients.

Heats, Pasteurises, and Mixes Beverages Efficiently

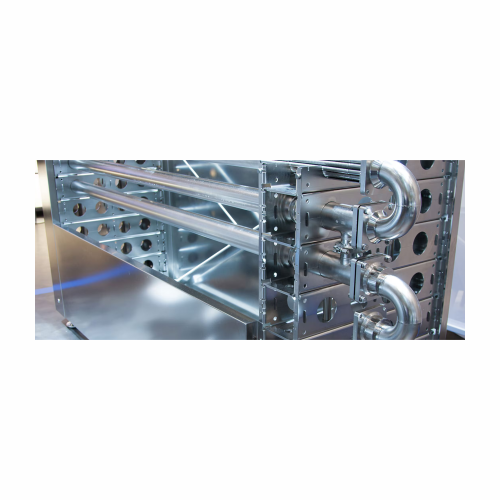

Krones’ Cross-Corrugated Tube Heat Exchanger excels in delivering efficient thermal treatment for a diverse range of liquid products, from beer to plant-based milk. Specially designed for continuous, high-speed operations in the food and beverage industry, this equipment uses unique cross-corrugated tubes to enhance turbulence, reducing the heat exchanger surface by up to 30% while maintaining product integrity.

This system is particularly effective for beverages containing particles, such as highly concentrated fruit suspensions, thanks to its ability to prevent partial underpasteurisation. Applications span from lager beer and chocolate milk to cola and green tea, handling processes like heating, pasteurising, mixing, and even sterilisation with precision.

The modular design offers flexibility, accommodating low to high output ranges, and is easily integrated into existing production lines. Energy efficiency is a core feature, with low dwell times and reduced thermal and pressure load, preserving flavors and nutrients. For cleaning and maintenance, its reduced dead-space design ensures thorough and quick cleaning via CIP/SIP systems, minimizing downtime and maximizing productivity.

Benefits

- Enhances product quality by preserving natural flavors and nutrients with gentle heating.

- Minimizes energy consumption and thermal stress through optimized tube design.

- Increases processing flexibility, accommodating a wide range of beverage viscosities and particulate content.

- Streamlines cleaning and maintenance with easily accessible design, maximizing operational uptime.

- Supports high-speed, continuous production, reducing bottlenecks and enhancing efficiency.

- Applications

- Water, Alternative proteins, Fruit mixtures, Milk and milk-based drinks, Spirits, Plant-based milk alternatives, Highly concentrated suspensions of fruit pieces, Juice, Soft drinks, Tea, Beer

- End products

- Green tea, Bottled water, Stout, Cola drinks, Skimmed milk, Gin, Oat milk, Almond milk, Orange juice, Soy protein beverage, Chocolate milk, Vodka, Apple juice, Lager beer, Black tea, Puree concentrates, Lemonade, Ale, Fruit cocktail blends

- Steps before

- Product mixing, Product deaeration

- Steps after

- Sterilization, Packing

- Input ingredients

- beverages, juice, milk, soft drinks, tea, water, products containing particles, highly concentrated suspensions of fruit pieces

- Output ingredients

- heated beverages, pasteurised beverages, drinks with reduced thermal impact, microbiologically safe products, products with preserved natural quality, evenly heated fruit pieces

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Product Heating Efficiency

- Substantially reduced energy consumption

- Heat Exchanger Type

- Cross-corrugated tubes

- Thermal Impact

- Low due to short dwell times

- Pressure Level

- Reduced

- Temperature Control

- Defined by killing kinetics of micro-organisms

- Output Range Flexibility

- High due to cross-corrugated tubes

- Minimum Color Change

- Ensured

- Surface Efficiency

- Reduces required surface by up to 30%

- Particle Treatment

- Prevents underpasteurisation in core flow

- Modular Design

- Available in compact and high-end variants

- Cleaning Method

- Reliable due to reduced dead space design

- Customisation

- Precisely adjusted to product characteristics

- Energy Requirement

- Reduced for thermal and pump energy

- Automation level

- Manual / Automated

- CIP/SIP

- CIP available

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- Reduced thermal energy requirement

- Cleaning method

- CIP / SIP

- Changeover time

- Quick changeover

- Thermal impact

- Low due to short dwell times

- Density/particle size

- Highly concentrated suspensions of fruit pieces and juice

- Machine footprint

- Compact / High-end

- Tube type

- Cross-corrugated

- Discharge method

- Gentle rotating

- Control panel type

- Modular design

- Heat exchanger surface configuration

- Precisely adjusted to product characteristics

- System design

- Complete system or individually designed

- Modular design

- Compact variant or high-end design

- Flexibility with cross-corrugated tubes

- Increased flexibility for product variety and output range

- Tubular module configuration

- Optimised number for gentle product heating

- Integration capabilities

- Customised with Krones measuring and configuration programs

- Product treatment system

- Specific configuration based on precise data