Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system enables high-speed, fully electric, servo-driven bottle production. Its efficiency in transitioning from standard to complex designs ensures it meets stringent production demands with quick installation and startup times.

Produces PET Containers Through Stretch-Blow Molding

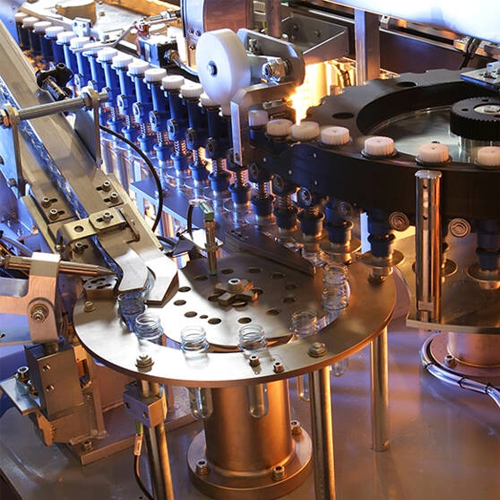

The SFL Linear Stretch-Blow Molding System from SIPA offers a flexible and efficient solution for producing PET containers tailored to the needs of diverse industries, including food, beverage, and pharmaceuticals. Operated fully electrically and servo-driven, this system integrates seamlessly into production lines, excelling in high-speed, continuous operations. It provides a user-centric platform, reducing installation and start-up times significantly.

It features precise preform heating and transfer using a servo-driven pitch-change system that enhances heating efficiency while ensuring gentle preform handling. With capabilities to accommodate preform feeding, heating, stretching-blowing, and bottles ejection processes, the system covers a wide array of end products—from mineral water and carbonated beverages to shampoos and pharmaceuticals.

The SFL’s design reduces total cost of ownership through energy-efficient operations, maintaining high output rates of up to 2,000 bottles per hour per cavity. Available with various cavity configurations from 2 to 8, the machine supports quick changeovers, crucial for operations requiring frequent product switches. The use of durable composite techno-polymers and self-lubricating components ensures minimum wear and low maintenance.

It is capable of producing containers requiring unique material specifications like lightweight, heat set, and pasteurizable options, providing solutions for a variety of filling environments, including ultra-clean and high-pressure processing. For manufacturers seeking robust production capacities and operational efficiency, SIPA’s SFL system promises customizable configurations and engineering support to meet specific production goals.

Benefits

- Boosts production efficiency with output rates up to 2,000 bottles per hour per cavity.

- Lowers operational costs with fully electric, energy-efficient design.

- Facilitates rapid product changeovers, minimizing production downtime.

- Provides flexibility to produce a variety of container types and sizes.

- Enhances sustainability by reducing the total cost of ownership and energy consumption.

- Applications

- Sauces, Spirits, Cosmetics, Soft drinks, Beer, Mineral water, Detergents, Non-food products, Tea, Functional drinks, Milk, Alcoholic beverages, Food products, Juice, Pharmaceuticals, Carbonated beverages, Isotonic drinks, Dressings, Edible oil, Dairy products

- End products

- Liquid soap dispensers, Bottled water, Olive oil bottles, Sports drinks, Ketchup bottles, Face wash bottles, Syrup bottles, Uht milk, Medicine bottles, Sunflower oil bottles, Orange juice, Sparkling water, Yogurt drink bottles, Vodka bottles, Salad dressings, Gin bottles, Disinfectant bottles, Shampoo bottles, Kombucha, Lemonade, Wine bottles, Iced tea, Craft beer bottles, Detergent containers

- Steps before

- Preform Feeding, Preform Handling, Preform Heating

- Steps after

- Bottle Ejection, Leak Testing, Cooling

- Input ingredients

- PET preforms, Composite techno-polymers chain, Blow molds, Preform tooling, Spindle for quick changeover, Preform ventilation system

- Output ingredients

- PET containers, Standard bottles, Heat set bottles, Refillable bottles, Wide mouth jars, Large size bottles, Personalized containers, Oval bottles

- Market info

- Output

- Up to 2000 bottles/hour/cavity

- Cavities Range

- 2 to 8

- Machine Type

- Fully electric

- Automation

- Servo-driven

- Clamp Stroke

- Variable

- Bottle Size

- Up to 30 liters

- Power Consumption

- Lower power consumption during idle mode

- Preform Feeding

- Continuous system

- Changeover Time

- Quick changeover, tool-less

- Heating System

- Preforms ventilation system with laminar flow

- Preform Transfer

- Servo-driven pitch-change system

- Stretch-Blowing

- Servo-driven blowing clamp

- Cooling

- No condensation on blow molds once not in production

- Material Types

- PET, rPET, OPP, PLA, PS, Tritan

- Production Flexibility

- Standard, heat set, refillable, wide mouth jars

- Working Mechanism

- Linear stretch-blow molding

- Automation level

- User centric platform with full process control

- Changeover time

- Quick-change system (option) for different neck diameters

- Installation and start-up time

- Extremely quick

- Continuous or Batch Operation

- Continuous production, adjustable

- CIP/SIP

- Not specified

- Cleaning method

- Not specified

- Energy efficiency

- Lower power consumption while idle or not in production

- Bottle Ejection

- Servo-driven unit for bottle discharge

- Air incorporation control

- Pre-blow flow regulation for each cavity

- Container Size

- Small to Large (up to 30 liters)

- Container Shape

- Standard, Heat Set, Refillable, Oval, Wide Mouth

- Material Type

- PET, rPET, OPP, PLA, PE, PS, Tritan

- Bottle Type

- Lighweight, Heat Set, Pasteurizable, Oval

- Barrier Type

- Light, Gas, Humidity

- Special Features

- Ultra-Clean, ESL, Aseptic

- Handle Solutions

- On neck handle, Post mold handle, In mold handle

- Cavities

- 2 to 8

- Clamp stroke

- Variable

- User-centric platform

- Full process control

- Installation and start-up time

- Extremely quick

- Cooling system

- No condensation on blow molds when idle

- Preform feeding system

- Continuous

- Preform handling

- Composite techno-polymers chain

- Bottle type compatibility

- Standard, Heat Set, Refillable, Oval, Large sizes, Wide mouth

- Control panel type

- User centric platform with full process control

- Integration possibilities

- Supports linear stretch-blowmoulding systems

- Variable clamp stroke

- Yes

- Preform feeding system

- Quick-change system for different neck diameters

- Servo-driven systems

- Pitch-change and transfer mechanisms

- Blowing clamp

- Servo-driven, no oil requirement

- Bottle discharge options

- Air, belt, or vacuum conveyor

- Quick start-up

- Extremely quick installation and start-up time