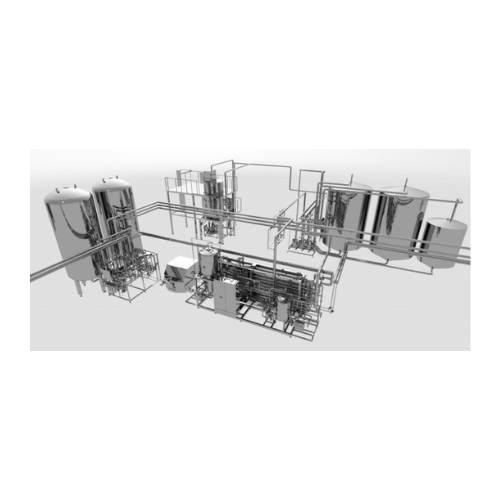

Juice reconstitution equipment for concentrated juice

Revolutionize your beverage production with advanced equipment designed to seamlessly reconstitute concentrated juices and ensure optimal flavor quality for shelf-stable products.

Processes and Reconstitutes Fruit Juices and UHT Milk

Bertuzzi’s comprehensive reconstitution line is designed to efficiently process and reconstitute a variety of fruit juices, nectars, and UHT milk. This system integrates seamlessly into your production line, accommodating continuous and fully automatic operations. It excels at blending concentrated juice with sugar syrup using dosing and mixing tanks, followed by homogenization and deaeration to enhance product shelf-life. Pasteurizers and tube-in-tube UHT sterilizers ensure that juices and dairy products are treated for safe, long-term storage. The line supports a wide range of end-products, including orange juice, cranberry nectar, and shelf-stable UHT milk. Equipped with CIP systems, it maintains stringent hygiene standards, and the equipment is designed to be energy efficient, reducing operational costs. With options tailored to meet specific process requirements and food-grade certifications, Bertuzzi offers custom engineering support to align with your facility’s needs.

Benefits

- Enhances product quality by ensuring consistent reconstitution and superior shelf-life.

- Reduces operational downtime with integrated, continuous processing capabilities.

- Lowers energy costs through efficient motor control and optimized process design.

- Meets international food safety standards with complete CIP system integration.

- Adapts easily to various production needs with customizable configuration options.

- Applications

- Concentrated juice, Uht milk, Nectar, Fruit juice, Fruit puree

- End products

- Shelf-stable uht milk, Cranberry nectar, Orange juice, Mango puree, Apple juice concentrate

- Steps before

- Concentration, Syrup Preparation

- Steps after

- Pasteurization, Sterilization, Filling, Packaging, CIP (Clean-in-Place)

- Input ingredients

- concentrated juice, sugar syrup, fruit puree, milk

- Output ingredients

- fruit juice, nectar, hot-filled juice, cold-filled juice, aseptic cartons

- Market info

- Bertuzzi is known for designing and manufacturing industrial equipment for the fruit and vegetable processing industry, specializing in producing machinery for juice and puree production, with a reputation for quality engineering and innovative solutions.

- Capacity

- Varies based on requirement

- Dosing type

- Automated mixing and dosing

- Automation

- Integrated solutions available

- Container type

- Glass bottles / Gable-top cartons / Aseptic cartons

- Cleaning method

- CIP system / Fully automatic

- Pasteurization method

- ThermoFlash

- Syrup preparation capacity

- Wide range available

- Deaeration

- Aroma recovery option

- Sterilization method

- Tube in tube UHT Sterilizer

- Homogenization pressure

- High pressure homogenizer

- Working mechanism

- Mixing of concentrated juice with sugar syrup

- Integrated steps

- Syrup preparation, pasteurization, dosing, mixing, homogenization, deaeration, sterilization, filling

- CIP principles

- Integrated cleaning procedures with BertuzziCipMatic

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Integrated automation solutions

- Cleaning method

- CIP / Fully automatic

- Energy efficiency

- Cost-effective solutions

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touchscreen / PLC

- Discharge method

- Pump / Gravity

- Tank shape

- Cylindrical

- Batch size compatibility

- Small / Large

- Integration options

- Modular / Inline

- Integration possibilities

- Syrup preparation line integration

- Control panel type

- Customized HMI

- Customization of dosing and mixing tanks

- Varying capacities available

- Deaerator with aroma recovery

- Optional feature

- Cleaning options

- Integrated CIP system