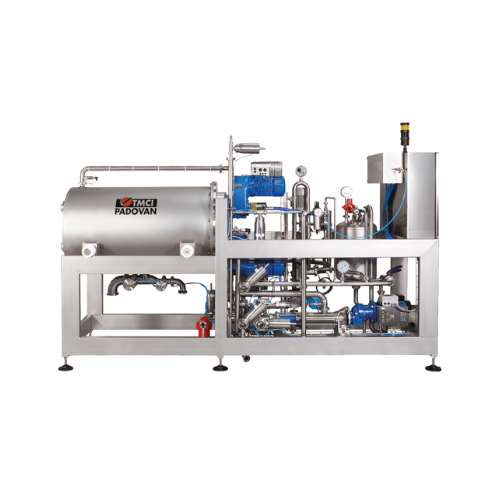

High solids crossflow filter for fruit juices and nectars

Eliminate the challenges of suspended solids in beverage production with a rotary crossflow filter that ensures high-quality filtration and minimal oxygen absorption, effectively reducing energy consumption and extending filtration cycles up to 72 hours without cleaning.

Filters and Clarifies High-Solid Liquids Continuously

The Dynamos from Blendtech offers a highly efficient solution for filtering and clarifying liquids with high solid content in beverage production. This pioneering rotary crossflow filter employs a calibrated back-wash system, utilizing rotating discs that actively spin through the liquid, ensuring thorough filtration without adjuvants. Specially designed for applications such as fruit juices, nectars, soft drinks, and syrups, the Dynamos delivers high-quality filtered products without oxygen absorption. With nominal flow rates ranging from 25 to 100 liters per square meter per hour, it can operate continuously for up to 72 hours without the need for cleaning, significantly reducing downtime. Its self-cleaning mechanism minimizes energy usage compared to conventional crossflow techniques. Constructed from robust stainless steel AISI 304, it caters to food and beverage industry requirements for durability and corrosion resistance. Available in models ranging from 1 to 20 square meters or more, this equipment integrates seamlessly into existing production lines while maintaining high-speed, automatic operation.

Benefits

- Enhances product clarity and quality without chemical additives.

- Minimizes energy consumption with efficient rotary disc technology.

- Extends operational cycles, reducing cleaning-related downtime.

- Preserves liquid freshness by preventing oxygen absorption.

- Offers scalable solutions with customizable filtration capacities.

- Applications

- Nectars, Soft drinks, Syrups, Fruit juices

- End products

- Chocolate syrup, Berry syrup, Apple juice, Peach nectar, Orange juice, Lemon-lime soda, Maple syrup, Cola beverage, Mango nectar, Herbal iced tea

- Steps before

- Mixing, Blending, Deaeration

- Steps after

- Clarification, Pasteurization, Aseptic Packaging

- Input ingredients

- fruit juices, nectars, soft drinks, syrups, liquids with high solids in suspension

- Output ingredients

- filtered product, high quality filtered liquids

- Market info

- BLENDTECH (Omnia Technologies) is known for manufacturing advanced engineered-to-order blending and processing equipment. Their expertise in customized solutions and reliability has earned them a strong reputation in the industrial equipment market.

- Material

- Stainless Steel AISI 304

- Automation

- Completely Automatic

- Filtration Type

- Rotary Crossflow

- Flow Rate

- 25-100 l/m²/h with lees

- Filtration Cycle Duration

- Up to 72 hours without cleaning

- Self-Cleaning Process

- Yes

- Disc Inspection

- Fully Inspectable

- Oxygen Absorption

- No Oxygen Absorption

- Energy Requirement

- Low compared to conventional crossflow techniques

- Model Size

- 1m² to 20m² and multiples

- Working mechanism

- Rotary crossflow with rotary discs

- Integrated steps

- Self-cleaning process

- Automation level

- Completely automatic

- CIP/SIP

- Available

- Batch vs. continuous operation

- Continuous with long filtration cycles

- Cleaning method

- Automatic back-wash system

- Energy efficiency

- Low energy requirement

- Abrasion resistance

- Stainless steel AISI 304

- Cleanability

- Self-cleaning process

- Corrosive resistance (e.g. acids)

- Stainless steel resistant

- Material

- Stainless Steel AISI 304

- Design Type

- Rotary Crossflow

- Size Range

- 1m² to 20m²

- Filtration Method

- Rotary discs

- Inspections

- Open and fully inspectable discs

- Filtration system

- Rotary crossflow

- Control panel type

- Fully automatic

- Integration possibilities

- Calibrated back-wash system

- Material

- Stainless steel AISI 304

- Self-cleaning feature

- Yes

- Disc inspection ability

- Open and fully inspectable