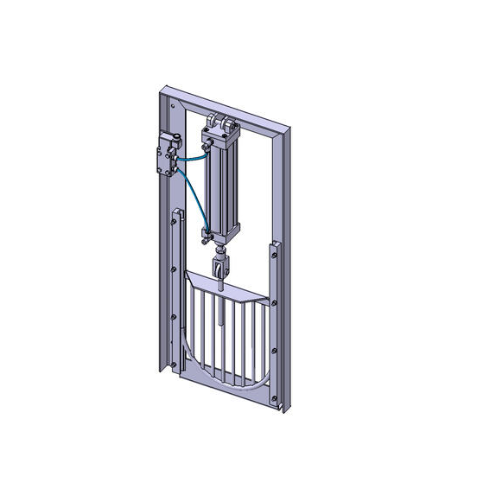

Pneumatically controlled dosing slide for pome fruit silos

Ensure consistent and controlled fruit discharge in your processing line, optimizing your flushing operations and preventing fruit damage with efficient pneumatic control.

Controls Fruit Discharge into Flushing Channels

The Dosing Slide from Bucher Unipektin is designed for precise management of pome fruit discharge in processing facilities. This robust equipment isolates fruit silos from flushing channels, enabling an even, controlled release of apples and pears for juice, puree, and cider production. The pneumatically activated slide valve ensures seamless integration with existing systems and features adjustable end positions, allowing for tailored discharge rates. Mounted directly at silo outlets, it minimizes fruit damage while maintaining water circulation when closed. The customizable timing of the slide’s pneumatic drive optimizes throughput and reduces processing time. Fabricated from durable materials, the Dosing Slide is engineered to withstand rigorous use while maintaining low maintenance demands, making it a reliable choice for beverage and food manufacturers focused on efficiency and product integrity.

Benefits

- Ensures uniform fruit discharge, improving processing consistency and product quality.

- Minimizes fruit damage during transfer, preserving raw material integrity.

- Reduces processing time with customizable, automated operation.

- Maintains water circulation to prevent system clogs and downtime.

- Easily integrates into existing systems with adjustable mounting options.

- Applications

- Fruit silos, Flushing channels, Pome fruits

- End products

- Pectin, Apple puree, Apple juice, Pear juice, Cider, Pear puree

- Steps before

- Harvesting, Sorting, Washing

- Steps after

- Juice Extraction, Pulp Processing, Fermentation

- Input ingredients

- pome fruit, apples, compressed air

- Output ingredients

- flushed fruit, evenly discharged fruit

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Opening and closing times

- Variable

- Drive Type

- Pneumatic

- Mounting Flange

- For flushing silo or flushing channel

- Channel/Outlet Size

- 400mm

- Compressed Air Inlet Pressure

- 4-5 bar

- Fruit Discharge Control

- Even and controlled

- Automation

- Controlled automatic discharge

- Adjustable End Positions

- Yes

- Automation level

- Automated control

- Controlled discharge

- Even and single layer

- Variable timing

- Adjustable opening/closing times

- Water circulation

- Enabled with slide closed

- Pneumatic drive

- Robust pneumatic activation

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Suitable for food products

- Cleanability

- Easy to clean

- Machine footprint

- Compact

- Discharge method

- Timed vertical movement

- Control panel type

- External controller/time switch

- Mounting size

- Channel/Outlet

- Mounting Flange Type

- On Flushing Silo / Flushing Channel

- End Position Adjustability

- Adjustable

- Opening and Closing Times

- Variable

- External Control Option

- External Controller / Time Switch

- Pneumatic Drive Control

- Solenoid Valve