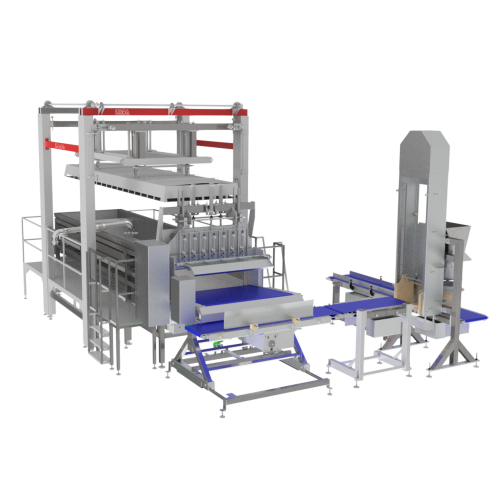

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pressing units, seamlessly transforming milk and plant-based ingredients into diverse cheese varieties while ensuring precise whey drainage and product consistency.

Forms and Presses Cheese Blocks Automatically

The Cheese Forming System from Reda Spa delivers precise automated moulding and pressing, perfect for dairy producers and cheese manufacturers handling hard and semi-hard varieties such as Gouda and Cheddar. This robust system integrates seamlessly into your workflow with its pre-pressing and moulding units, featuring a unique draining belt system that efficiently collects whey. Capable of processing an array of products including whipped cream, coffee cream, and other cream varieties, as well as plant-based drinks and juices, this fully automated and compact cheese forming solution optimizes your production line. It combines direct and indirect heating methods, incorporating a highly efficient sterilization process to maintain product integrity and quality, making it highly sought after in food and beverage processing industries. Built with a high-efficiency design, this equipment reduces energy use significantly, supports continuous operation, and is constructed from stainless materials to ensure durability and ease of maintenance. Fully customizable, it supports integration with existing automated systems, adhering to industry standards for safety and hygiene.

Benefits

- Enhances operational efficiency with fully automated moulding and pressing processes.

- Reduces energy consumption through optimized combined heating systems.

- Improves product quality by maintaining consistent cheese block formation.

- Integrates easily with existing production lines, minimizing installation time.

- Ensures hygienic processing with corrosion-resistant materials and design.

- Applications

- Plant-based drinks, Wine, Milk, Hard cheeses, Semi-hard cheeses, Juices, Beer, Dairy

- End products

- Whipped cream, Swiss cheese, Coconut milk, Lager, Monterey jack cheese, Pale ale, Grape juice, Crème brûlée, Smoothies, Chardonnay, Oat milk, Almond milk, Orange juice, Crème fraîche, Cooking cream, Coffee cream, Cheddar cheese, Sparkling wine, Bechamel sauce, Apple juice, Soy milk, Single cream, Edam cheese, Merlot, Butter cream, Pastry cream, Colby cheese, Gouda cheese

- Steps before

- Clarification, Standardization, Pre-pressing, Pre-moulding

- Steps after

- Sterilization, Aseptic filling, Packing, Brine Filtration

- Input ingredients

- raw milk, whey, cream, milk, plant-based drinks, juices, wine, beer

- Output ingredients

- cheese blocks, high-density products, whipped cream, coffee cream, cooking cream, pastry cream, butter cream, besciamella, single cream, creme flambè, crème fraiche, aseptic filling products

- Market info

- Product Type

- Hard and semi-hard cheeses

- Heating System

- Direct steam heating

- Heating System

- Indirect steam injection

- Combined Heating System

- Direct steam and indirect heating

- Automation Level

- Fully automated

- Design

- Pre-mounted and compact

- Aseptic Phase

- Special flash cooler

- Operating Efficiency

- High efficiency

- Drainage System

- Special draining belt

- Energy Consumption

- Reduced energy costs

- Process Method

- Raw milk clarification, standardization, deaeration, homogenization, sterilization

- Production Autonomy

- Long

- Process Type

- All-in-One solution

- Working Mechanism

- Automatic and precise cheese block formation

- Integrated Steps

- Draining belt system for whey drainage

- Batch vs. Continuous Operation

- Batch processing

- Heating Type

- Direct heating / Indirect heating

- Combined Systems

- Steryflex with direct steam and indirect heating

- Automated Process

- Fully automated

- Process Phase

- Aseptic phase with flash cooler

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cheese Type

- Hard and Semi-hard

- Machine footprint

- Pre-mounted and compact design

- Control panel type

- Fully automated process

- Discharge method

- Automatic and precise cheese block formation

- Compact footprint

- Pre-mounted and compact design

- Integration possibilities

- Fully automated process

- Compact design

- Pre-mounted and compact design

- Thermal regeneration capability

- High thermal regeneration