No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuring premium taste and longevity for delicate and sparkling wines.

Ensures Oxygen-Free Beverage Filling

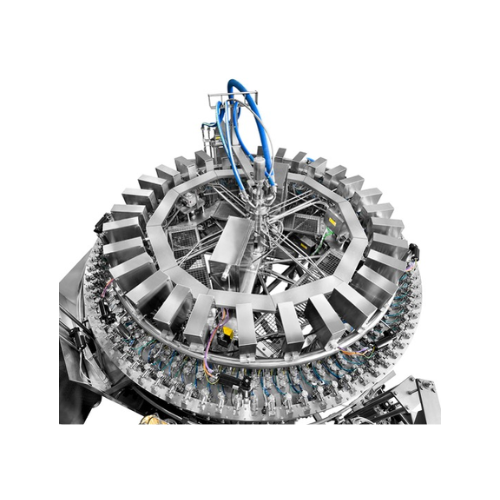

Gruppo Bertolaso’s No-Oxygen Isobaric Filler sets a new standard in beverage production by minimizing oxygen exposure and contamination during filling operations. Utilizing a cutting-edge isobaric filling valve, this equipment is tailored for a range of end products, including red and white wines, sparkling varieties like champagne and prosecco, as well as spirits, juices, and sodas. Engineered for continuous, high-speed operations, it integrates seamlessly into bottling lines with its ability to handle various liquid products efficiently. The electropneumatic design ensures reduced overpressure, optimizing filling quality and maintaining minimal oxygen pickup across diverse applications. Crafted from AISI 316 stainless steel, the filler prioritizes sanitation, featuring a simple pipe design that efficiently removes gases and prevents external contact with the product. Ideal for wine producers and beverage manufacturers, this highly customizable system supports various production needs, from bottle rinsing to corking, and is backed by Bertolaso’s extensive engineering support for bespoke solutions.

Benefits

- Minimizes oxidation, preserving delicate flavors and extending shelf life.

- Enhances production efficiency with continuous, high-speed operation.

- Ensures product integrity with zero oxygen pickup during filling.

- Reduces operational costs with optimized energy consumption.

- Supports versatile production with customizable configurations for various beverage types.

- Applications

- Water, Spirits, Wines, Drinks, Juices

- End products

- Lemonade, Soda, Mineral water, Champagne, Apple juice, Red wine, Cognac, Vodka, Prosecco, Orange juice, White wine, Sparkling wine

- Steps before

- Wine treatment, Bottle rinsing

- Steps after

- Corking, Packing

- Input ingredients

- still wine, slightly sparkling wines, sparkling wines, spirits, juices and drinks, water, wine treatment materials

- Output ingredients

- bottled still wines, bottled slightly sparkling wines, bottled sparkling wines, protected wines, contaminant-free product

- Market info

- Bertolaso (Omnia Technologies) is renowned for manufacturing high-quality, engineered-to-order bottling and packaging machinery, with extensive expertise in providing customized solutions for wineries and the beverage industry, ensuring efficiency, precision, and reliability in production processes.

- Filling Method

- Gravity / Low vacuum / No-oxygen / Isobaric

- Filling System Type

- Automatic / Electropneumatic

- Filling Valve Type

- Isobaric / Electropneumatic with AISI 316 stainless steel

- Filling Capability

- Sparkling / Slightly sparkling / Still wine

- Oxygen Increase

- Zero increase

- Oxidation Protection

- No-oxygen system

- Microbiological Protection

- Yes

- Contamination Protection

- Yes

- Automation

- High capacity

- Energy Efficiency

- Reduced energy consumption

- Material

- AISI 316 stainless steel

- Pressure Type

- Isobaric / Overpressure

- Cleaning Capability

- Maximum filler sanitation

- Production Efficiency

- Constant high levels

- Working Mechanism

- Gravity and/or Low Vacuum

- Working Mechanism

- Isobaric Systems

- Integrated Steps

- Wine Treatment, Bottle Rinsing, Filling, Corking

- Oxidation Control

- No-Oxygen Systems

- Cleaning Method

- Sanitation with Aisi 316 Stainless Steel

- Automation Level

- Advanced Filling Technologies

- Filling Type

- Sparkling, Still, and Slightly Sparkling Wines

- Filling Valve

- Electropneumatic with Aisi 316 Stainless Steel Pipe

- Batch vs. Continuous Operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Type

- Glass / PET Bottles

- Filler type

- Gravity / Low vacuum / Isobaric / Electropneumatic

- Material of construction

- Aisi 316 stainless steel

- Footprint

- Compact design

- Discharge method

- No-oxygen ambient contact / Low oxygen pickup

- Control panel type

- Advanced technological control

- Control panel type

- Advanced HMI/PLC options

- Integration possibilities

- Inline with bottling lines

- Filling capability

- Slightly sparkling/still wines

- Material of Construction

- Aisi 316 Stainless Steel