Horizontal form-fill-seal systems for pouch packaging

For production lines that demand efficient pouch creation, these high-speed horizontal form-fill-seal systems offer precise sealing and minimal material waste, ensuring quality packaging for diverse products.

Forms, Fills, and Seals Pouches Efficiently

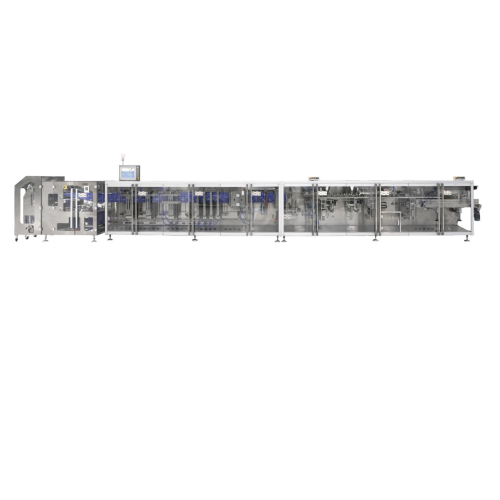

The HFFS Machine from The Food Machinery Company stands out for its robust design and precision in creating pouches from a roll of film. Specially engineered for continuous and high-speed operations, it forms, fills, and seals various pouch types, efficiently handling applications across snacks, confectionery, powders, and liquids. Operating with an intuitive user interface, the HFFS Machine allows for seamless integration into your existing packaging line, reducing downtime and enhancing productivity. It boasts customizable settings for pouch dimensions and sealing techniques, meeting diverse packaging needs. Built for durability, it ensures superior seal integrity, maintaining product freshness and protection. With reduced film wastage, it optimizes material usage and promotes sustainability. The machine supports food manufacturers, snack producers, and liquid packaging companies, providing scalable solutions for a wide range of end-products such as potato chips, chocolate bars, and fruit juices.

Benefits

- Increases production efficiency with high-speed pouch creation.

- Maintains product freshness through precise sealing integrity.

- Reduces material costs by minimizing film wastage.

- Customizable settings allow flexibility for diverse packaging requirements.

- Enhances operator productivity with a user-friendly interface.

- Applications

- Ready meals, Sauces, Snacks, Confectionery, Food packaging, Powders, Liquids

- End products

- Potato chips, Chocolate bars, Protein powder, Fruit juice, Tomato ketchup, Microwaveable pasta meals

- Steps before

- Material Selection, Film Loading, Product Preparation

- Steps after

- Sealing, Packing, Quality Inspection

- Input ingredients

- roll of film, snacks, confectionery, powders, liquids

- Output ingredients

- pouches, packaged snacks, packaged confectionery, packaged powders, packaged liquids

- Market info

- The Food Machinery Company Ltd. is known for manufacturing bespoke food processing equipment, like conveyors and mixers, offering engineering expertise for industrial-scale food production, backed by a reputation for quality and tailored solutions in the UK and international markets.

- Speed

- High-speed capabilities

- Capacity

- Varies by product type

- Seal Integrity

- Superior seal integrity

- Automation

- User-friendly interface

- Material Usage

- Efficient material usage

- Construction

- Robust and durable

- Customization

- Customisable options

- Product Versatility

- Handles snacks, powders, liquids, etc.

- Working mechanism

- Horizontal Form-Fill-Seal

- Integrated steps

- Forming, Filling, Sealing

- Automation level

- PLC-controlled

- Changeover time

- Quick and efficient

- Cleaning method

- Manual/CIP

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Optimised for low waste

- Abrasion resistance

- High

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Food-grade materials

- Density/particle size

- 0.5–2.5 g/cm³

- Control panel type

- User-friendly interface

- Robust construction

- High-quality materials

- Pouch creation size

- Customisable

- Control Panel Type

- User-friendly Interface / Touchscreen

- Integration Possibilities

- Customisable Machine Settings

- Pouch Dimensions

- Customisable

- Sealing Techniques

- Customisable