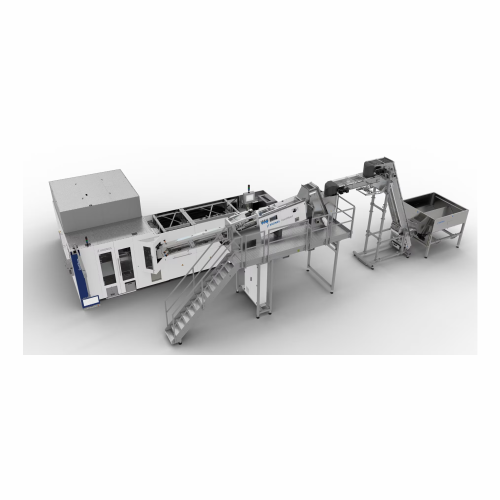

Stretch blow moulder for Pet containers

Optimize energy efficiency and production versatility with this stretch blow moulder, designed for seamless integration into bottling lines, reducing energy usage by up to 15% while producing a wide range of beverage containers, from PET to glass, ensuring consistent quality and operational fluidity.

Produces and Inspects PET Beverage Containers

The Contiform Heatset from Krones is a stretch blow moulder that sets the benchmark in the flexible production of PET containers. Engineered for efficiency, it integrates seamlessly into high-speed bottling lines, producing a wide range of containers for beverages such as mineral water, juice, and plant-based milk alternatives. This equipment utilizes an innovative infrared heating module and electromagnetic stretching system, achieving up to 11% lower heating energy consumption and enabling precise container formation. With an output capacity tailored to meet the most demanding production needs, it supports automatic operations with real-time PLC control, ensuring minimal downtime and optimal throughput. The modular design allows for precise configuration based on specific production requirements, from lightweight to heavy preforms, with customizable components such as preform feed systems and blowing modules. Constructed with hygiene and durability in mind, the Contiform Heatset facilitates quick changeovers and easy maintenance, featuring a no PET dust policy and minimal dead space in blowing stations to reduce scrap rates. This machine is an asset for beverage manufacturers seeking reliable and sustainable production solutions.

Benefits

- Enhances production efficiency with continuous, high-speed operations.

- Lowers energy consumption by up to 11% through advanced infrared heating.

- Minimizes scrap rates with precise, skip-and-run technology.

- Simplifies changeovers and maintenance, reducing downtime.

- Supports a diverse range of container types in a single machine.

- Applications

- Carbonated beverages, Milk-based drinks, Hot-filled bottles, Water, Bottled liquids, Pet containers, Milk, Non-carbonated beverages, Spirits, Plant-based milk alternatives, Juice, Soft drinks, Cans, Glass bottles

- End products

- Carbonated soft drink bottles, Energy drink bottles, Gin bottles, Mineral water bottles, Ready-to-drink milk bottles, Coconut water bottles, Lactose-free milk bottles, Iced tea bottles, Infused water bottles, Tonic water bottles, Flavored water bottles, Soy milk bottles, Sports drink bottles, Almond milk bottles, Vodka bottles, Beer cans, Tea bottles, Cold brew coffee bottles, Protein drink bottles, Lemonade bottles, Sparkling water bottles, Whiskey bottles, Juice bottles, Kombucha bottles

- Steps before

- Preform manufacturing, Preform storage, Preform feeding

- Steps after

- Filling, Capping, Labelling, Package inspection, Conveying, Palletising

- Input ingredients

- preforms, PET preforms

- Output ingredients

- blown PET containers, PET bottles, containers for non-carbonated beverages, containers for carbonated beverages, hot-filled bottles

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Blowing module capacity

- Up to 3.5 litres

- Heating module type

- Linear infrared for preforms up to 160 mm

- Blowing stations

- Electromagnetic stretching system

- Heating energy consumption

- Up to 11% reduction

- Footprint size

- Up to 15% smaller

- Preform feed system

- Contifeed with automatic adjustment

- Compressed air usage

- Two-stage Air Wizard Plus recycling

- Automation

- Intelligent process control

- Transfer system

- Five-point heating mandrel

- Container variety

- Non-carbonated, carbonated, hot-filled

- User interface

- Large touch-screen

- Working mechanism

- Stretch blow moulding

- Integrated steps

- Blow moulding, filling, capping

- Automation level

- PLC-controlled

- Energy efficiency

- Low energy consumption technology

- Cleaning method

- Hygienic design with easy cleanability

- Batch vs. continuous operation

- Inline continuous

- Changeover time

- Quick and automatic adjustment

- Compressed-air recycling

- Two-stage Air Wizard Plus system

- Air incorporation control

- Optimised compressed-air recovery

- CIP/SIP

- Automatic troubleshooting and cleaning

- User-friendliness

- Touch-screen interface

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Up to 15% smaller footprint due to reduced dead space

- Modular design

- Individually equipped modules

- Blowing module

- With blowing stations

- Infrared heating module

- Linear heating for preforms up to 160 mm

- Control panel type

- Touch-screen for machine operation

- Feed/discharge method

- Contifeed preform feed system

- Compactness

- Compact high-output block solutions

- Discharge method

- Seamless drive concept in block configuration

- Control panel type

- Touch-screen interface

- Integration possibilities

- Block-synchronised systems

- Heating module options

- Linear infrared heating module

- Blowing module options

- Blowing stations for containers up to 3.5 litres

- Preform feed system

- Gravity or air-assisted

- Optional modules

- Prejet preform interior cleaning system

- Inspection system

- PET-View for integrated quality control

- Hygienic design

- Soft-tilting preform tipper

- Compressed-air recycling

- Air Wizard Plus system