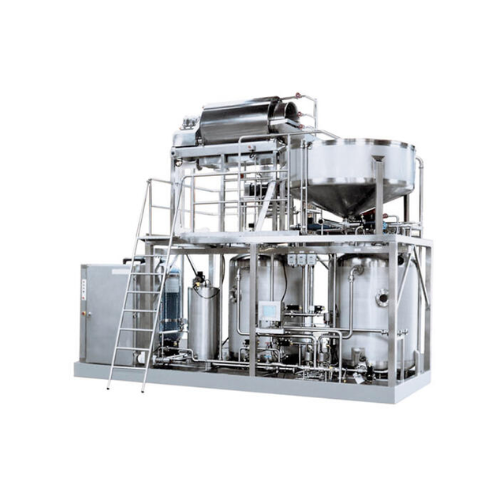

Adsorber for haze stabilisation in clear fruit juices

Achieve precise haze stabilization and debittering in fruit juices with advanced adsorption technology that enhances flavor and clarity without additives.

Processes and Clarifies Juices and Extracts

Bucher Unipektin’s Industrial Adsorption System enhances juice processing by implementing a fully automated, PLC-controlled operation that specializes in the stabilization, decolourization, and debittering of fruit and citrus juices. This system helps eliminate post-haze formation and reduces bitterness by employing specific resins to adsorb undesired components at the molecular level during a continuous processing cycle. It’s ideal for creating clear apple and pear juices, de-bittered orange juice, and haze-free lemon juice, as well as extracting valuable anthocyanins from elderberry and grapeseed juice and phenolic bioactive compounds from peel extracts. Operating at capacities ranging from 500 to 50,000 liters per hour, it offers stainless steel construction to meet local regulatory standards. The system supports continuous operation through multiple train setups and easy resin regeneration, backed by specialized R&D and engineering support.

Benefits

- Enhances juice quality by preventing haze and bitterness without additives.

- Lowers processing costs through fully automatic, continuous operation.

- Customizable for various juice types, maximizing production flexibility.

- Supports high throughput with minimal downtime across diverse plant sizes.

- Ensures regulatory compliance with durable stainless steel construction.

- Applications

- Juice extracts, Peel extracts, Cloudy juices, Citrus juices, Clear juices, Fruit juices

- End products

- De-bittered orange juice, Grape anthocyanin extract, Apple juice, Pear juice, Black carrot anthocyanin extract, Haze-free lemon juice, Elderberry anthocyanin extract, Aronia anthocyanin extract, Phenolic-rich bioactive extracts

- Steps before

- Juice Extraction, Pulp Reduction, Filtration

- Steps after

- Sterilization, Packaging, Flavor Enhancement

- Input ingredients

- clear fruit juices, cloudy fruit juices, apple juice, pear juice, citrus juices, orange juice, lemon juice, peel extracts, juice or pomace from aronia, elderberry, grape, black carrot

- Output ingredients

- haze-stabilised juice, decolourised juice, debittered juice, juice with reduced patulin, juice with reduced HMF, limonin reduced juice, hesperidin reduced juice, astringency reduced extracts, anthocyanins extracted, phenolic components extracted

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Plant Capacity

- 500–50, 000 litres/hr or more

- Automation

- Fully automatic, PLC control and PC based operation systems

- Material

- Stainless steel construction

- Processing Type

- Continuous operation, multiple trains

- Resin Type

- Adsorbent polymer resin in a fixed bed

- Functionality

- Haze stabilisation, decolourisation and debittering

- Component Reduction

- Reduction of patulin and HMF levels, reduction of Limonin and Hesperidin

- Operating system

- PLC control and PC-based operation

- Haze stabilisation

- Yes

- Colour reduction

- Partial colour reduction

- Debittering

- Yes, reduces Limonin

- Astringency reduction

- Yes, for peel extracts

- Process type

- Fixed bed adsorption

- Regeneration capability

- Resin regeneration

- Continuous operation

- Available, multiple trains

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Yes

- Abrasion resistance

- High

- Cleanability

- Easy

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Low

- Viscosity

- Low to medium

- Foaming

- Minimal

- Container size and shape

- Varies

- Haze formation risk

- High for apple and citrus juices

- Machine footprint

- Varies with plant size

- Material

- Stainless steel construction

- Plant size range

- 500 to 50, 000 litres/hr

- Control panel type

- Fully automatic, PLC control and PC based operation systems

- Discharge method

- Juice displacement from column

- Resin type

- Adsorbent polymer resin in a fixed bed

- Custom-built

- Yes, to local regulations

- Control panel type

- PLC control and PC based operation

- Construction material

- Stainless steel

- Plant size

- 500 to 50, 000 litres/hr

- Operation mode

- Fully automatic

- Regeneration system

- Customizable for specific resins

- Local regulation adaptability

- Custom-built to local regulations