Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to improve efficiency in filtration, concentration, and separation processes, ensuring optimal quality and performance for a wide range of dairy and beverage products.

Filters and Concentrates Liquid Food Products

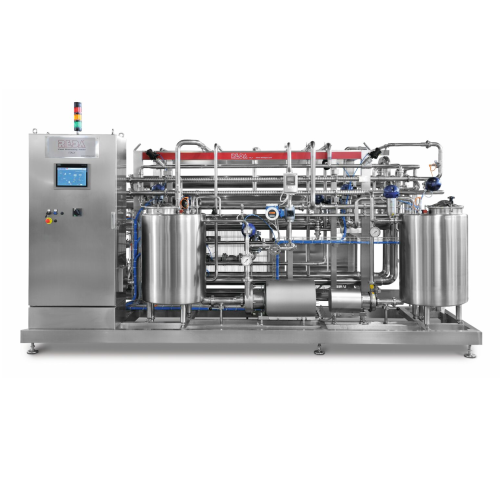

The modular membrane filtration system from Reda Spa offers a versatile solution for dairy and beverage producers seeking efficient liquid separation and concentration. Utilizing microfiltration, ultrafiltration, nanofiltration, and reverse osmosis technologies, this system is engineered to handle a range of applications, including milk, plant-based drinks, juices, wine, and beer. Ideal for producing skim milk, whey protein concentrates, and fruit juice concentrates, it also facilitates lactose-free milk and various plant-based milk production.

Designed for continuous automated operation, the system integrates seamlessly into existing production lines with its PLC controls and modular skid design. This ensures easy installation, commissioning, and high throughput with low maintenance requirements. Reda’s technology reduces operating costs through energy-efficient processes and offers material construction in corrosion-resistant stainless steel. The system is also equipped with a CIP (Clean-in-Place) system, ensuring reliable hygiene and minimal downtime, along with customization options to suit specific processing needs.

Benefits

- Enhances product quality by ensuring precise filtration and separation.

- Minimizes operational costs with energy-efficient processing and low maintenance design.

- Facilitates seamless integration into existing lines with modular construction and PLC controls.

- Reduces downtime and contamination risk with an effective CIP cleaning system.

- Customizable configurations offer tailored solutions for diverse product applications.

- Applications

- Plant-based drinks, Wine, Milk, Whey, Juices, Beer, Cheese processing

- End products

- Fruit juice concentrates, Coconut milk, Lager, Oat milk, Almond milk, Skim milk, Soy milk, Pale ale, Dealcoholized wine, Whey protein concentrate, Mozzarella cheese, Wine concentrate, Lactose-free milk, Cheddar cheese, Whey protein isolate

- Steps before

- Clarification, Bacteria Removal, Cream Separation

- Steps after

- Low Temperature Evaporation, Brine Filtration, Cheese Forming, Curd Making, Bacteria Removal, Pasteurization, Separators for Milk Skimming

- Input ingredients

- milk, whey, cream

- Output ingredients

- concentrated whey, clarified milk, cream separation, concentrated wine, de-alcoholized wine

- Market info

- Reliability

- High

- Efficiency

- Optimized for low operating costs

- Maintenance Requirement

- Easy

- Installation

- Pre-assembled and modular skid

- Commissioning

- Easy installation and commissioning

- Flexibility

- High

- Performance

- High

- Filtration type

- Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis

- Whey Concentration

- Complements automatic separators pre-treatments

- Working mechanism

- Membrane filtration

- Modular design

- Pre-assembled skid

- Automation level

- PLC-controlled

- Changeover time

- Easy installation and commissioning

- CIP/SIP

- Easy maintenance

- Operating efficiency

- Low operating costs

- Process flexibility

- Complementary to multiple processes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Skid-mounted design

- Pre-assembled and modular

- Compact footprint

- Optimized for easy installation

- Feed/discharge method

- Membrane filtration system

- Maintenance accessibility

- Easy maintenance design

- Control panel type

- Touchscreen / HMI / Manual buttons

- Integration possibilities

- SCADA / PLC Systems

- Modular design

- Pre-assembled skid