Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory needs with this high-pressure solution, ideal for testing formulations and scaling up efficiently from research to production phases.

Homogenizes and Pumps Liquid and Slurry Products

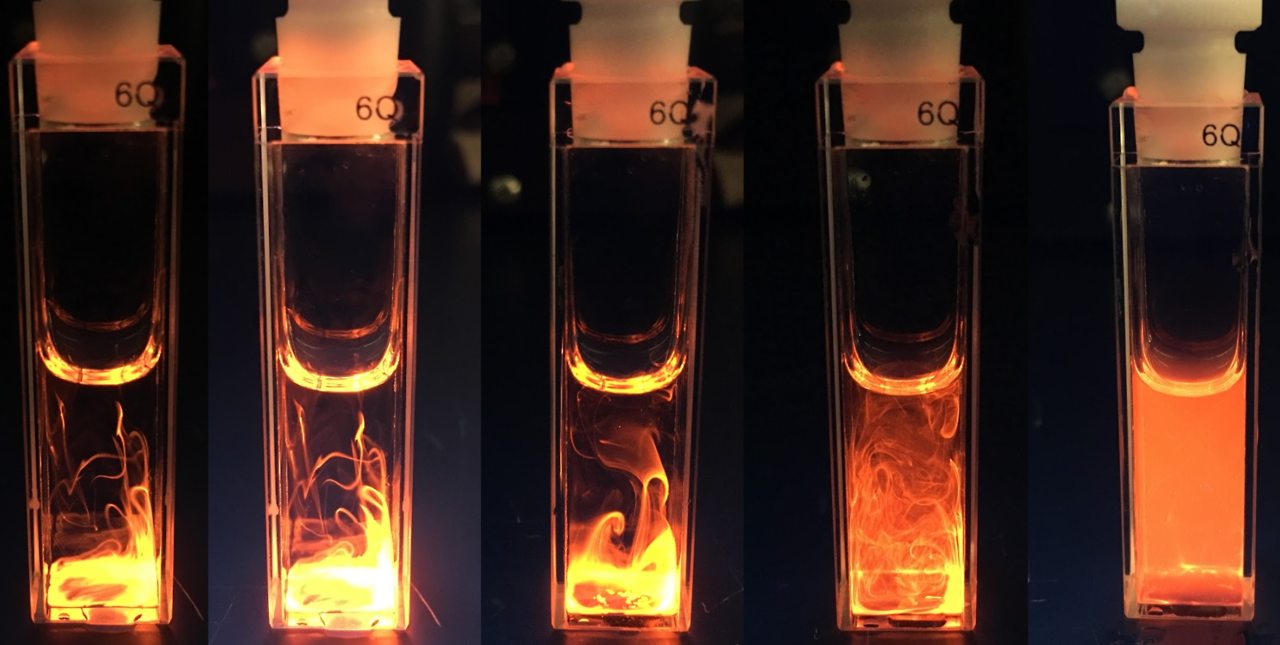

The QUARK from Bertoli is a compact tabletop laboratory homogenizer, engineered for precise homogenization and dispersion tasks in sectors like dairy, food and beverage, chemical, and biotech. It features a single plunger design capable of handling liquid and slurry products with abrasive or viscous properties. Operating at a pressure of up to 2,000 bar with a capacity of 3 liters per hour, it achieves consistent particle size reduction crucial for products such as milk, emulsions, and liposome formulations. The QUARK integrates seamlessly into research and development environments, offering a minimum sample volume of just 10 ml, making it ideal for scaling up from test samples to larger production batches. The option for ATEX configuration enhances its versatility for use with volatile substances. Built with stainless steel components, it ensures durability and ease of cleaning, complying with industrial safety standards. Whether it’s creating uniform cosmetic creams or dispersing chemical suspensions, the QUARK provides reliable and efficient performance in demanding lab settings.

Benefits

- Enables precise scale-up from laboratory samples to production, ensuring consistent product quality.

- Minimizes sample waste with a low minimum volume requirement, optimizing research resources.

- Operates effectively with abrasive and viscous materials, expanding application versatility.

- ATEX configuration allows safe processing of volatile substances, enhancing operational safety.

- Facilitates quick setup and operation on laboratory benches, improving workflow efficiency.

- Applications

- Pharma and biotech, Cosmetic, Chemical and nano dispersion, Food and beverage, Dairy

- End products

- Face creams, Milk, Chemical suspensions, Lotions, Liposome formulations, Emulsions, Protein solutions, Yogurt, Fruit juice, Tomato sauce

- Steps before

- Mixing, Formulation, Blending, Heating

- Steps after

- Packaging, Cooling, Quality Control, Filling

- Input ingredients

- abrasive product, viscous product, syringes

- Output ingredients

- homogenized product, nano dispersion, chemical dispersion, food and beverage product

- Market info

- Bertoli, part of the Interpump Group, is known for its expertise in designing and manufacturing high-pressure homogenizers and positive displacement pumps, serving industries like food processing, pharmaceuticals, and cosmetics, with a reputation for reliability and innovation.

- Power

- 0.75 kW

- Pressure

- 2000 bar

- Capacity

- 3 l/h

- Plunger number

- 1

- Weight

- 50 Kg

- Water Consumption

- 10 l/h

- Product inlet/outlet

- welding flanges DIN 11851

- Minimum volume

- 10 ml

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- Yes

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Compatibility with syringe feeding

- Yes

- Inlet/outlet type

- Welding flanges DIN 11851

- Tabletop design

- Yes

- Plunger configuration

- Single plunger