Aseptic filling for high and low acid beverages

Ensure aseptic integrity while maximizing operational efficiency with a compact filling system that seamlessly integrates sterilization, rinsing, filling, and capping processes for a wide range of liquid products.

Sterilizes, Rinses, Fills, and Caps Beverages

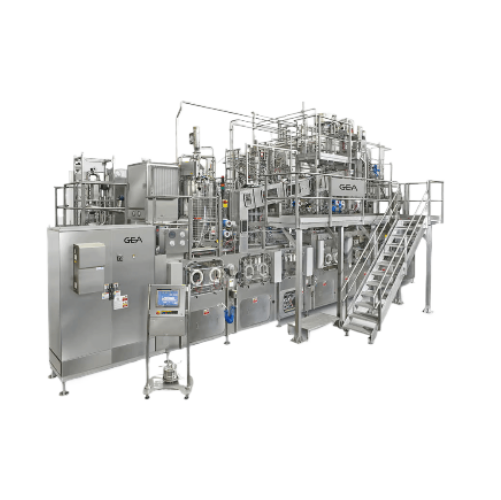

The Modulbloc Aseptic Filling System from GEA is a comprehensive solution for beverage and dairy producers seeking a reliable method for processing high and low acid products. This system is distinguished by its compact design, integrating sterilizing, rinsing, filling, and capping processes on a single base frame, enclosed within a microbiological isolator to ensure aseptic conditions are maintained.

Utilizing peracetic acid (PAA) sterilization technology, Modulbloc effectively handles PET bottles and closures, ensuring thorough internal and external cleansing. The system features a rapid, high-efficiency spraying mechanism that minimizes residual peroxide levels to less than 0.5 ppm, aligning with FDA regulations. The automatic nozzle check via ‘Smart Sensor’ enhances the reliability of the sterilization process.

Suitable for producing a variety of end-products including fruit juices, carbonated drinks, and milk-based beverages, Modulbloc supports continuous, low to medium-speed operations, with line availability up to 165 hours without intermediate SOP cycles. It offers a throughput ranging from 1,250 to 22,000 bottles per hour, adapting to both high and low acid beverage requirements.

Designed for ease of maintenance, the system reduces wear parts within its rinser and sterilizer components, supports flexible bottle feeding from depalletizers or integrated blow-fill systems, and conserves water with reduced rinsing needs. Additionally, it conforms to stringent FDA standards, making it ideal for various industries including food, beverage, and pharmaceuticals, where maintaining product integrity and operational efficiency are crucial.

Benefits

- Ensures product safety with FDA-compliant sterilization, maintaining residual peroxide levels below 0.5 ppm.

- Minimizes maintenance downtime through reduced wear parts in sterilizer and rinser components.

- Increases line efficiency with continuous operation capability for up to 165 hours without SOP interruptions.

- Saves space with a compact design suitable for facilities with limited room or small-scale production lines.

- Conserves water usage with a reduced rinsing time, optimizing resource management.

- Applications

- Milk-based drinks, Pet bottles, High acid beverages, Sensitive beverages, Low acid beverages, Dairy industry

- End products

- Ready-to-drink coffee, Kefir, Bottled water, Vitamin water, Flavored milk, Sport drinks, Almond milk, Iced tea, Soy milk, Herbal infusions, Energy drinks, Yogurt drinks, Probiotic beverages, Carbonated soft drinks, Pet-packaged milk, Fruit juices

- Steps before

- Depalletizing, Blow molding, Preform sterilization

- Steps after

- Packaging, Sealing, Labeling

- Input ingredients

- PET bottles, closures, peracetic acid (PAA) solution, sterile water, high acid (HA) beverages, low acid (LA) beverages, flat caps, sport caps

- Output ingredients

- sterilized PET bottles, sterilized closures, beverages

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- PLC-controlled

- Cleaning method

- CIP / SIP / manual

- Capacity

- 1, 250 to 22, 000 b/h

- Chemical used

- Peracetic acid (PAA)

- Cycle time without SOP

- 165 hours

- Container type

- PET

- Residual Peroxide Level

- Less than 0.5 ppm

- Rinsing Time

- Reduced

- Water Consumption

- Less than 1 m³/hour

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP

- Changeover time

- Minimal due to integrated design

- Bottle feed flexibility

- Depalletizer to integrated blow-fill system

- Line availability

- 165 hours

- Sterilization technology

- Peracetic acid (PAA)-based

- Corrosive resistance (e.g. acids)

- Peracetic acid (PAA)

- Container type

- PET Bottles

- Compact footprint

- Single base frame

- Carousel configuration

- Sterilizer, rinser, filler, capper

- Bottle size compatibility

- PET bottles

- Machine design

- Compact

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / MES

- Compact design

- Single base frame

- Carousels customization

- Sterilizer / Rinser / Filler / Capper