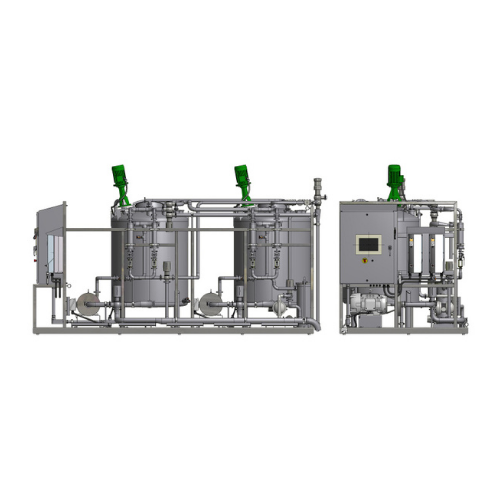

Two-stage defect removal system for citrus juice

Ensure your juice production achieves maximum yield and purity with a two-stage system that effectively reduces defects by recycling underflow, streamlining your processing line for superior quality beverages.

Removes Defects and Concentrates Juice Efficiently

The READYGo™ CYCLONE from JBT is a two-stage defect removal and juice concentration system designed for fruit and beverage processors seeking enhanced purity and efficiency. This skid system employs double cyclone technology with a second stage underflow recycle process to optimize defect removal and concentrate yields. Suitable for citrus and a variety of fruits and vegetables, it produces clean juice streams ready for pasteurization or sterilization. With a capacity to process up to 110 GPM (25,000 l/h), the system supports continuous, automated operations, integrating seamlessly into existing production lines. Automation of tank levels and juice flow rates reduces complexity, while the precision-engineered components ensure reliable performance. The equipment is constructed with materials suited for food processing, ensuring safety and hygiene, with minimal maintenance requirements.

Benefits

- Increases juice yield and quality by efficiently removing defects.

- Enhances production efficiency with continuous, automated operation.

- Lowers operational costs through reduced energy consumption and material waste.

- Supports diverse product lines, from citrus juice to nut-based beverages.

- Seamlessly integrates with existing processes for streamlined production.

- Applications

- Beverages, Fruits, Fruit processing, Nuts, Citrus processing, Juices, Vegetable processing

- End products

- Citrus juice, Lemon pulp, Orange concentrate, Nut-based beverages, Blended fruit smoothies, Vegetable juice

- Steps before

- Grinding, Juicing, Extraction

- Steps after

- Pasteurization, Sterilization, Concentration

- Input ingredients

- raw juice, citrus fruit

- Output ingredients

- clean pulpy juice stream

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- 110 GPM (25, 000 l/h)

- Process Type

- Two-stage defect removal

- Operation

- Second stage underflow recycle

- Technology

- Double cyclone with second stage recycle

- Fruit Compatibility

- Citrus fruit variety

- Juice Preparation

- Pasteurization or sterilization

- Working mechanism

- Two-stage defect removal

- Flow type

- Inline continuous

- Automation level

- Automated juice flow rate control

- Recycling process

- Second stage underflow recycle

- Yield enhancement

- Double cyclone technology

- Capacity

- Up to 110 GPM (25, 000 l/h)

- Compatibility

- All citrus fruit varieties

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Juice and pulp processing

- Fruit variety

- All citrus fruit varieties

- Machine footprint

- Skid-mounted

- Discharge method

- Continuous flow

- Feed method

- Gravity-fed or pumped

- Control system type

- Automated with PLC

- Integration possibilities

- Compatible with existing systems

- Control panel type

- Touchscreen HMI

- Modular design

- Yes