Inline real-time fluid quality monitoring system

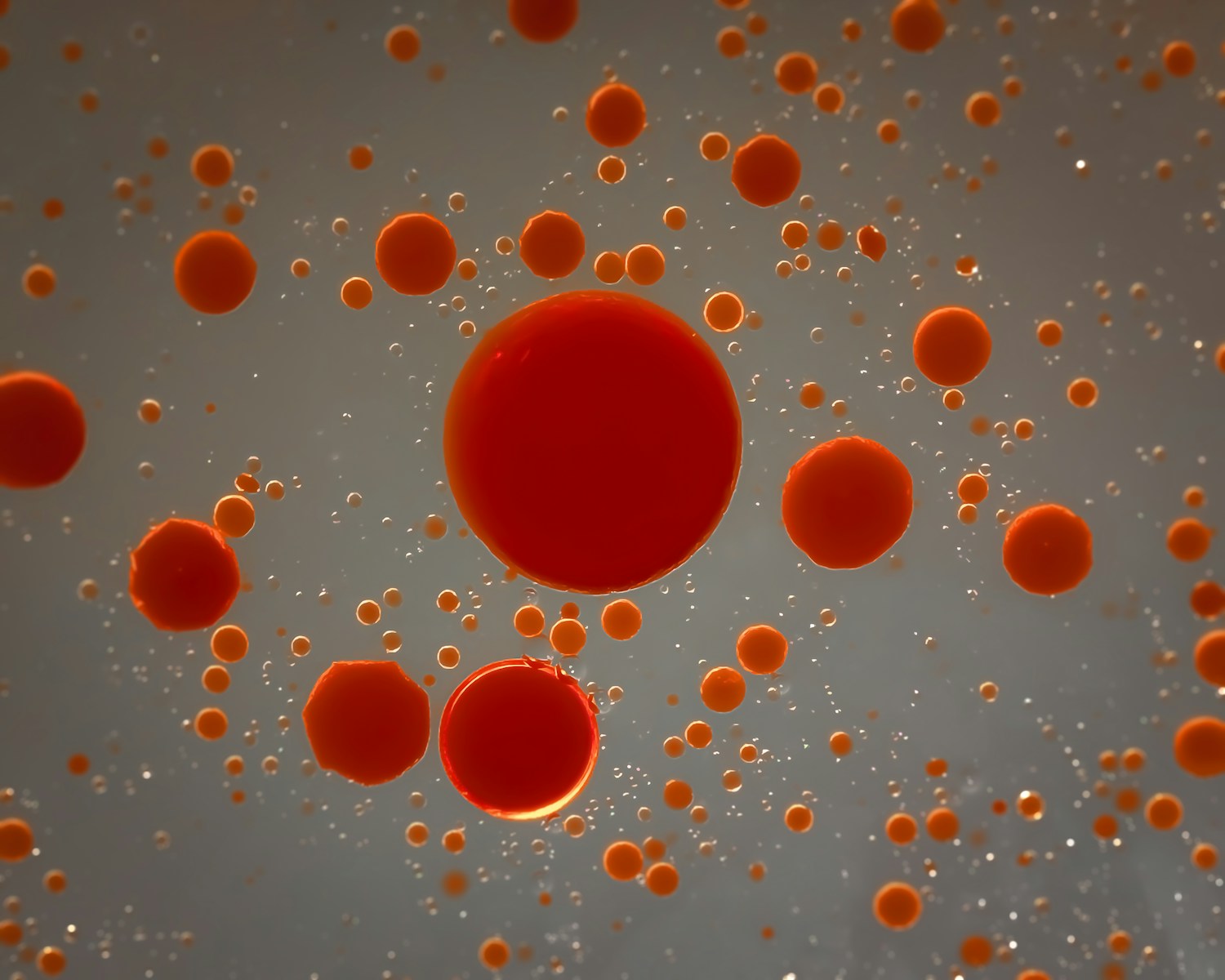

Optimize fluid quality control with continuous, inline measurements that adjust parameters in real-time to enhance production efficiency and reduce energy consumption, ensuring consistent product quality while minimizing waste.

Monitors and Adjusts Fluid Quality in Real-Time

The NiSoMate® Quality Analyzer by GEA is an inline system designed to optimize fluid monitoring in real-time. It features a plug-and-play setup equipped with sensors that measure parameters like particle size distribution and density. This system is ideal for industries such as dairy, pharmaceutical, and cosmetics, suitable for a range of products from UHT milk to cosmetic lotions. Operating continuously, it adjusts operating parameters to maintain the desired product quality at minimal pressures, enhancing energy efficiency. The NiSoMate® integrates seamlessly with existing production lines, including large plants and laboratory units, and supports automated alerts for deviations from quality setpoints, reducing waste and ensuring consistent operational outcomes. Its hygienic design meets stringent industry sanitary standards, while optional machine learning capabilities enhance resolution and adaptability.

Benefits

- Enhances product quality consistency with real-time adjustments, reducing waste.

- Optimizes energy consumption by minimizing operational pressure.

- Improves safety and hygiene with non-contact sensors and compliant design.

- Flexible integration supports both new and retrofitted production lines.

- Reduces total cost of ownership through efficient, continuous monitoring.

- Applications

- Food, Beverage, Cosmetic, Chemical, Dairy, Pharmaceutical

- End products

- Uht milk, Vaccines, Liquid pharmaceuticals, Pharmaceutical creams, Detergents, Cheese, Cosmetic lotions, Chemical emulsions, Carbonated drinks, Yogurt, Fruit juices, Essential oils

- Steps before

- Emulsification, Grinding, Homogenization

- Steps after

- Sterilization, Packaging, Quality Control

- Input ingredients

- fluid, processed product

- Output ingredients

- particle size distribution, density, product quality, energy-optimized product

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Inline Monitoring

- Real-time quality analysis

- Automation

- Automated adjustment of operating parameters

- Energy Optimization

- Lowest pressure for energy efficiency

- Measurement Parameters

- Particle size distribution, density

- Calibration

- Direct product calibration

- Data Storage

- Parameters stored for reference

- Hygienic Design

- Non-contact sensors

- Installation Flexibility

- Lab to industrial plant, new or retrofit

- Compliance

- Food industry sanitary regulations

- Machine Learning

- Continuous resolution improvement

- Inline vs. batch operation

- Inline Continuous

- Real-time quality monitoring

- Yes

- Automation level

- Automated feedback loop

- Integration capabilities

- Plug and play installation

- Parameter adjustment

- Continuous adjustment

- Energy efficiency

- Optimized for low pressure

- Hygienic design

- Non-contact sensors

- Calibration method

- Direct product calibration

- Product suitability

- All fluid types

- Customizable installation

- Lab to industrial plant

- Deviation alert system

- Yes

- Waste reduction

- Continuous monitoring

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Installation type

- Lab unit / Industrial plant / Retrofit

- System footprint

- Compact

- Installation type

- Plug and play

- System compatibility

- New and retrofit installations

- Hygienic design

- Yes

- Temperature probe

- Included

- Control panel type

- PLC / HMI Integration

- Integration possibilities

- Retrofit on existing units

- Installation flexibility

- Lab unit to large industrial plant

- Calibration customization

- Direct product calibration

- Machine learning system

- Continuous resolution improvement