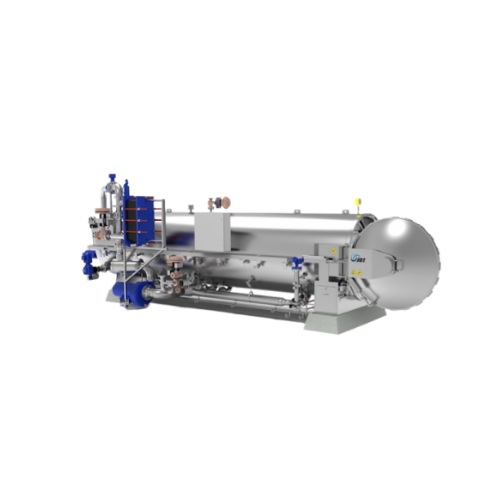

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization processes with this advanced batch retort, designed for optimal agitation and temperature management, minimizing resource usage while accommodating various container types for seamless integration into your production line.

Sterilizes and Agitates Diverse Food Products

The SuperAgi Agitating Batch Retort from JBT FoodTech offers advanced sterilization solutions for diverse food processing needs. Its patented rotary water coupling and integrated spray pipes deliver efficient heat distribution, reducing process times and ensuring precise control of temperature and pressure for reliable sterilization. Ideal for applications in baby food, sauces, and beverages, it supports a wide range of container types, from rigid to flexible. Featuring a streamlined vessel design, you gain significant savings in steam, air, and water consumption. The system integrates seamlessly into automated production lines with PLC controls, ensuring consistent quality and safety. Constructed with high-quality materials, it offers durability and ease of maintenance, complemented by JBT’s engineering support for customized configurations.

Benefits

- Enhances product safety with precise, reproducible sterilization.

- Cuts energy and resource usage by minimizing steam, air, and water consumption.

- Offers flexibility for processing various container types, expanding product range.

- Increases efficiency with reduced process times and consistent heat distribution.

- Seamless integration reduces operational disruptions in automated production lines.

- Applications

- Beverages, Soups, Sauces, Seafood, Ready meals, Pet food, Meat, Fruits, Oils, Nuts, Dressings, Poultry, Seasonings, Baby food, Juices

- End products

- Olive oil, Ranch dressing, Infant formula, Chicken breast, Orange juice, Iced tea, Soy sauce, Canned tuna, Marinara sauce, Almond butter, Applesauce, Lasagna, Dog food, Chicken noodle soup

- Steps before

- Filling, Packaging, Container Loading

- Steps after

- Cooling, Labeling, Quality Inspection, Storage

- Input ingredients

- raw baby food ingredients, raw fruits, nuts, juice, beverages, oils, soups, sauces, seasonings, dressings, raw pet food ingredients, poultry, meat, seafood, ready meal components

- Output ingredients

- shelf-stable baby food, processed fruits, processed nuts, sterilized juice, sterilized beverages, shelf-stable oils, packaged soups, ready sauces, sealed seasonings, dressed foods, shelf-stable pet food, processed poultry, cooked meat, canned seafood, ready meals

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Drum size

- 1500 mm

- Heat distribution

- Most efficient

- Process time

- Reduced

- Temperature control

- Precise

- Pressure control

- Precise

- Container flexibility

- Rigid, semi-rigid, flexible

- Steam usage

- Reduced

- Cooling/process water usage

- Reduced

- Automation

- Pre-programmed recipes

- Rotary water coupling

- Patented

- Flow meter

- Absolute

- Level probe

- Yes

- Micro cooling

- Yes

- Working mechanism

- Agitating Batch

- Integrated steps

- Sterilization and Cooling

- Batch vs. continuous operation

- Batch

- Automation level

- PLC-controlled

- Cleaning method

- Micro cooling

- Container type

- Rigid, semi-rigid, flexible

- Container size

- Various

- Vessel Size

- 1, 500 mm

- Drum Structure

- Light perforated plate

- Drum and Shell Void

- Narrow

- Basket Clamping

- Top Clamping

- Spray Pipes

- Integrated in Drum

- Control panel type

- Touchscreen

- Integration possibilities

- SCADA

- Container flexibility

- Rigid, semi-rigid, flexible

- Drum size

- 1500 mm

- Spray-pipes configuration

- Integrated