Grist milling unit for breweries and distilleries

Optimize your milling process with a versatile unit capable of handling various starch sources, improving efficiency and consistency by ensuring optimal comminution for enhanced enzymatic activity and product quality.

Processes Diverse Starch Sources with Precision

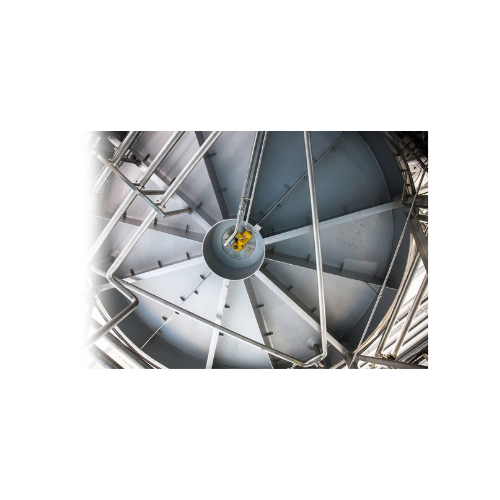

The T-Rex Grist Milling Unit from Ziemann Holvrieka is an engineered-to-order solution expertly crafted for breweries and distilleries seeking to enhance their milling operations. This unit stands out due to its dual capability of dry and wet milling, accommodating a wide range of starch sources such as malt, barley, rice, and maize. Its unique design utilizes multiple disks on opposing shafts, increasing the milling zone threefold compared to conventional rollers, leveraging shear, compressive, and cutting stresses for rapid, energy-efficient processing. Ideal for producing malt grist and distilled spirits mash, the T-Rex seamlessly integrates into automated production lines with ease, offering quick disc removal for minimal downtime. Designed to suit continuous, high-speed operations, this compact unit is also retrofit-friendly, fitting seamlessly within existing systems. Its low CAPEX and OPEX contribute to cost-effectiveness, while its robust design ensures long lifecycle and reduced maintenance requirements, making it an optimal choice for industrial-scale processing.

Benefits

- Lowers operational costs with reduced energy consumption and minimal maintenance requirements.

- Enhances production flexibility by easily switching between multiple starch sources.

- Increases milling efficiency with a threefold larger milling zone for faster processing.

- Optimizes product quality through precise comminution for improved enzymatic degradation.

- Seamlessly integrates into existing systems, reducing retrofit complexity and costs.

- Applications

- Distilling, Hard seltzer, Beer, Juice, Edible oil, New food, Dairy

- End products

- Dairy adjuncts, Beer wort, Distilled spirits mash, Malt grist, Barley grist, Juice pulp preparation, Hard seltzer base, Maize grist, New food high-starch ingredients, Rice grist

- Steps before

- Purification, Drying, Grinding, Emulsification

- Steps after

- Fermentation, Filtering

- Input ingredients

- malt, barley, rice, maize, adjuncts

- Output ingredients

- grist

- Market info

- Ziemann Holvrieka is known for its expertise in providing industrial engineered-to-order equipment for breweries. They design and manufacture advanced brewing systems and solutions, earning a strong reputation for quality and innovation in the brewing industry.

- Milling Options

- Dry and Wet

- Material Compatibility

- Malt, Barley, Rice, Maize, Adjuncts

- Milling Zone Increase

- Threefold compared to similar-length roller pairs

- Design

- Compact and Lightweight

- Maintenance

- Easy disc removal and replacement

- Integration

- Analog to Fully Automated Systems

- Roller Lifetime

- Long

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- Abrasion resistance

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cleanability

- Easy removable discs

- Corrosive resistance (e.g.,acids)

- Yes

- Machine Footprint

- Compact design

- Weight

- Lightweight

- Design

- Toothed disk arrangement

- Milling Zone

- Threefold increase compared to traditional roller mills

- Construction

- Multiple disks on two opposite shafts

- Control panel type

- Analog / Digital / PLC

- Integration possibilities

- Analog / Fully automated systems

- Disc profile change

- Simple exchange

- Footprint size

- Compact design

- Weight demands

- Lightweight

- Retrofitting capability

- Seamless integration