Industrial homogenizers for liquid processing

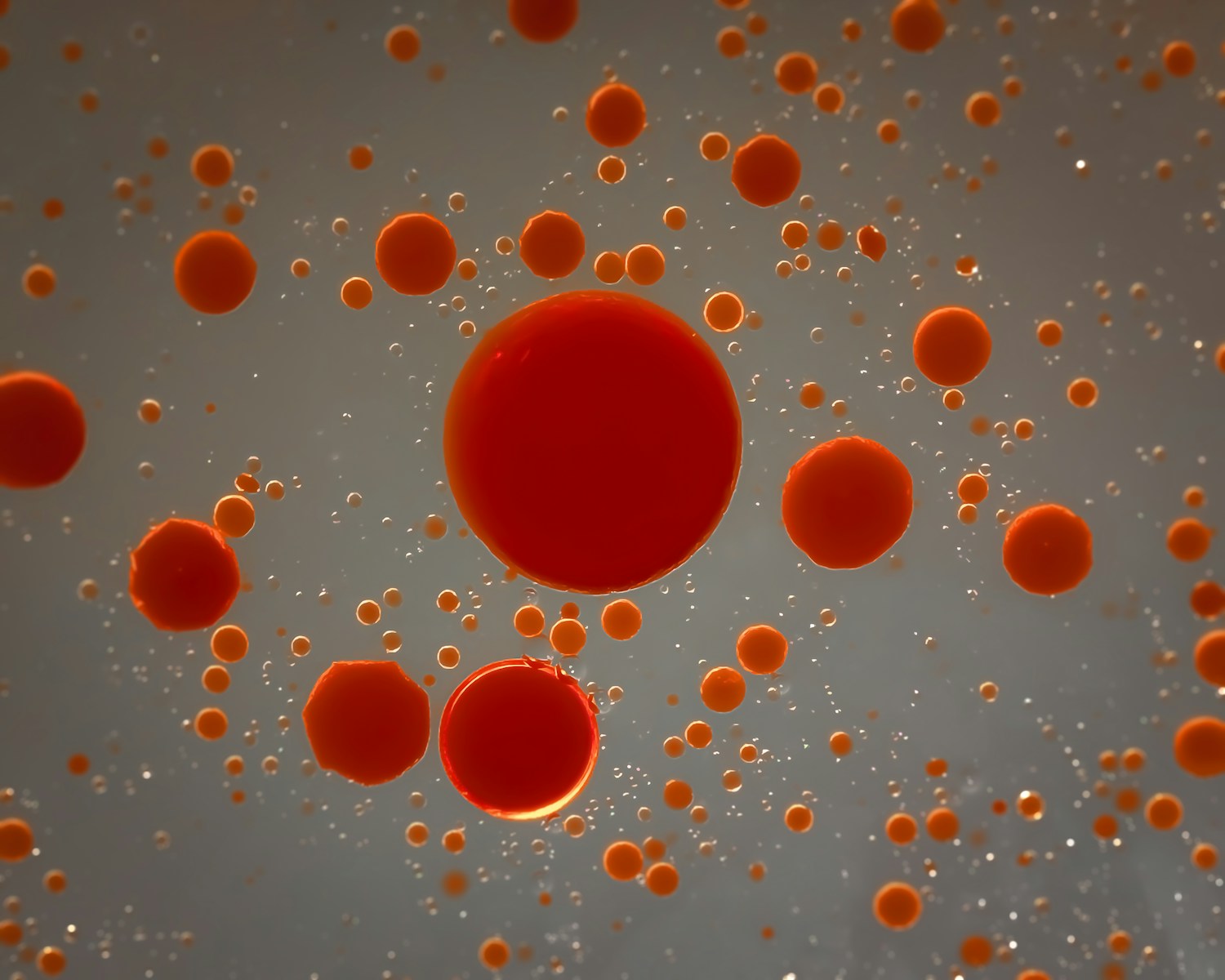

Achieve consistent product quality and energy efficiency in liquid processing with these advanced high-pressure homogenizers, ideal for improving viscosity, texture, and stability across a wide range of products, from dairy emulsions to pharmaceutical creams.

Homogenizes and Stabilizes Liquid Products

The HST HL Series Homogenizers from HST Krones are cutting-edge high-pressure machines designed to enhance the quality of liquid products by ensuring uniform texture and stability across a wide range of applications. These homogenizers are critical for processing dairy, food, beverage, pharmaceutical, and cosmetic products, offering a solution to prevent separation and improve viscosity and taste.

Using robust multi-stage homogenizing valves, they ensure efficient blending at pressures between 100 to 1,500 bar, with throughput capabilities ranging from 10 to 60,000 liters per hour. The HST HL series integrates seamlessly with existing production lines and offers energy-saving operations with its advanced variable-speed motor controls.

Constructed from high-grade materials including stainless steel and ceramics, these units are engineered for durability and resistance to corrosion, accommodating highly demanding production environments. With options for aseptic processing, the HST HL Series supports compliance with stringent industry standards, such as GMP, making them suitable for both sterile and non-sterile environments.

Additionally, these homogenizers feature CIP (Clean-In-Place) systems to facilitate straightforward and efficient cleaning, reducing downtime and maintaining operational hygiene. Customization in valve and piston materials supports tailored applications, ensuring compatibility and optimal performance across varied product formulations.

Benefits

- Enhances product quality by maintaining consistent texture and stability.

- Increases production efficiency with high throughput capacity.

- Reduces energy costs through optimized motor control.

- Ensures compliance with regulatory standards for sterile processing.

- Minimizes maintenance time with easy-to-clean CIP systems.

- Applications

- Food, Beverage, Sterile products, Cosmetics, Uht products, Chemical, Juice-based drinks, Yogurt, Soy beverages, Dairy products, Pharmaceutical

- End products

- Cream, Carbonated beverages, Uht milk, Face creams, Milk, Hair conditioners, Pharmaceutical emulsions, Lotions, Soy milk, Chemical emulsions, Industrial lubricants, Flavored drinks, Sterilized milk, Fruit juices

- Steps before

- Heat treatment, UHT processing

- Steps after

- Packaging, Sterilization

- Input ingredients

- milk products, cream, juice-based drinks, soy beverages, yogurt, UHT products, sterile products

- Output ingredients

- homogenized milk, improved viscosity cream, enhanced taste drinks, improved texture juices, better mouth feel soy beverages, stable yogurt, cream stability UHT or sterile products

- Market info

- Unison Process Solutions is known for designing and manufacturing custom-engineered process equipment for the dairy, beverage, and food industries, emphasizing innovation, quality, and tailored solutions to meet specific customer needs efficiently.

- Pressure Range

- 100 to 1, 500 bar

- Flow Rate

- 10 to 60, 000 L/hr

- Material of Valves

- Stainless steels, sintered materials, ceramics

- Piston Coating

- Chrome-plated, ceramic, HST coating

- Piston Material

- Standard, chrome-plated, ceramic, special HST coating

- Valve Control

- Pneumatic or hydraulic

- Automation

- Energy-saving, low-noise

- Aseptic Design

- Available

- Uses superheated steam,condensate,or sterile water

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Flow rate

- 10 to 60, 000 litres per hour

- Pressure range

- 100 to 1, 500 bar

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Automation level

- Manual / PLC / SCADA

- Aseptic design

- Optional aseptic / septic

- Density/particle size

- 0.5–2.5 g/cm³

- Compact footprint

- Yes

- Discharge method

- Inline Continuous

- Control panel type

- Pneumatic / Hydraulic

- Control panel type

- Pneumatic / Hydraulic

- Valve type

- PLUG / PILOTED / Multigap

- Customization of machine design

- Product-centric design and production