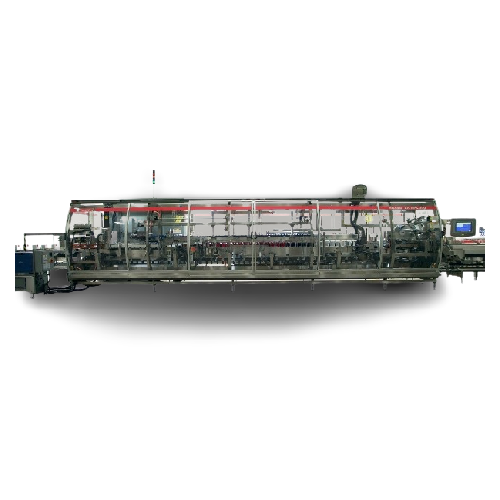

Beverage multi-pack cartoner for cans and bottles

Optimize your beverage production line with high-speed, continuous multi-packing capabilities for seamless cartoning and end-load insertion of various drink containers.

Multi-Packs Cans and Bottles

The Meridian® XR MPS-300 from R.A Jones is a high-speed multi-pack cartoner expertly designed to meet the demands of beverage manufacturers. This system stands out with its continuous operation capability, employing end load and side load insertion techniques to efficiently process a diverse array of cans and bottles. It excels in cartoning and box filling, managing products such as soda cans, fruit juice bottles, and iced coffee cartons with ease. Capable of packing up to 300 products per minute, the MPS-300 integrates seamlessly into existing production lines, supported by PLC-controlled operations for enhanced automation. Constructed with robust materials, it utilizes fluted corrugate fiberboard for secure packaging, and its flexible design accommodates quick size changeovers within 30 to 40 minutes. The machine is adaptable for varying product dimensions and maintains high hygiene standards, making it suitable for industries such as soft drinks, beer, and RTD manufacturing.

Benefits

- Maximizes production speed with its capability to handle up to 300 packs per minute.

- Offers flexibility in packaging formats, accommodating a wide range of can and bottle dimensions.

- Reduces manual intervention through continuous and automated cartoning and box filling processes.

- Enhances line integration with end and side load capabilities, ensuring seamless operation within existing systems.

- Supports quick changeovers, minimizing downtime and increasing overall efficiency in multi-product operations.

- Applications

- Coffee, Tea, Juice, Soft drinks, Ready-to-drink (rtds), Beer

- End products

- Energy drink cans, Soda cans, Herbal tea boxes, Craft beer bottles, Fruit juice bottles, Iced coffee cartons

- Steps before

- Bottle Filling, Can Filling, Product Inspection

- Steps after

- Sealing, Labeling, Distribution

- Input ingredients

- cans, bottles

- Output ingredients

- cartons, multi-pack

- Market info

- R.A Jones (Coesia Group) is known for its expertise in designing and manufacturing packaging equipment and automation solutions, specializing in cartoning, pouching, and high-speed filling, with a strong reputation for innovation and reliability in the industry.

- Machine depth

- 2270 mm

- Machine height

- 2430 mm

- Machine length

- 13577 mm

- Machine weight

- 8900 kg

- Performance mode

- Continuous

- Product changeover

- n/a

- Size changeover

- 30 - 40 min

- Max pack height

- 463 mm

- Min pack height

- 101 mm

- Max pack length

- 274 mm

- Min pack length

- 101 mm

- Max pack width

- 254 mm

- Min pack width

- 76 mm

- Packaging closing

- Glue

- Packaging material

- Fluted Corrugate Fiberboard

- Packaging orientation

- Horizontal

- Packaging type

- Prefolded Carton

- Operating speed

- 300 ppm

- Operating mode

- Continuous

- Insertion mode

- End Load/Side Load

- Product changeover

- n/a

- Size changeover

- 30 - 40 min

- Carton material

- Fluted Corrugate Fiberboard

- Packaging orientation

- Horizontal

- Packaging type

- Prefolded Carton, Carton box

- Container type

- Cans / Bottles

- Machine depth

- 2270 mm

- Machine height

- 2430 mm

- Machine length

- 13577 mm

- Machine weight

- 8900 kg

- Insertion mode

- End Load/Side Load

- Max pack height

- 463 mm

- Min pack height

- 101 mm

- Max pack length

- 274 mm

- Min pack length

- 101 mm

- Max pack width

- 254 mm

- Min pack width

- 76 mm

- Control panel type

- HMI/PLC

- Integration possibilities

- Modular design for varying pack sizes

- Customization

- Flexible packaging range

- Packaging orientation

- Horizontal

- Insertion mode

- End Load/Side Load