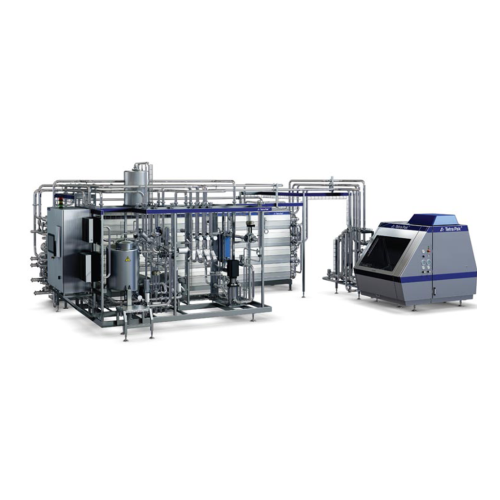

Pasteurizer for beverage processing

Achieve precise temperature control with continuous pasteurization, ensuring product safety and optimal quality for beverages ranging from juices to carbonated drinks.

Executes Continuous Pasteurization and Temperature Treatment

The Tetra Pak® Pasteurizer BF is a highly efficient solution for continuous beverage temperature treatment. It operates with an aseptic or hot-fill design utilizing either a tubular or plate heat exchanger, ensuring safe and quality processing for varied liquid products. This unit is particularly suited for producing juices, nectars, isotonic drinks, smoothies, and sensitive carbonated beverages. With a capacity range from 3,000 to 55,000 liters per hour, it integrates seamlessly into existing operations through its robust automation features, including a 21.5” touch panel interface for real-time monitoring. The Pasteurizer BF enhances energy efficiency significantly by optimizing temperature settings based on beverage pH values, yielding up to 20% energy savings. Designed with a focus on minimizing product loss, it features a low-loss balance tank configuration and an automated hibernation mode. Customizable options such as deaerators and eco-cooling further enhance water efficiency, saving up to 5,500 liters per hour. Made to withstand harsh production environments, this pasteurizer supports your production goals with flexibility and reliability.

Benefits

- Ensures food safety through precise temperature control and monitoring, reducing risk of contamination.

- Minimizes energy consumption with optimized settings, delivering up to 20% in energy savings.

- Decreases product loss with an innovative low-loss balance tank design.

- Enhances operational efficiency and reduces labor with seamless automation via a user-friendly interface.

- Provides flexible operation with variable capacity, adaptable to various production needs from 3,000 to 55,000 liters per hour.

- Applications

- Isotonic beverages, Beverages, Smoothies, Tomato juice, Milk-juice beverages, Still drinks, Energy drinks, Nectars, Carbonated soft drinks, Juices

- End products

- Taurine energy drink, Tomato cocktail, Protein smoothie, Apple juice, Strawberry banana smoothie, Peach nectar, Orange juice, Grape juice, Sports drinks, Lemon-lime soda, Cola with premium fibers, Electrolyte water, Caffeine energy drink, Mango nectar

- Steps before

- Juice extraction, Blending, Mixing, Homogenization

- Steps after

- Cooling, Filling, Packaging, Labeling

- Input ingredients

- juices, nectars, still drinks, juice drinks, isotonic beverages, tomato juice, smoothies, energy drinks, milk-juice beverages, sensitive carbonated soft drinks

- Output ingredients

- pasteurized juices, pasteurized nectars, pasteurized still drinks, pasteurized juice drinks, pasteurized isotonic beverages, pasteurized tomato juice, pasteurized smoothies, pasteurized energy drinks, pasteurized milk-juice beverages, pasteurized carbonated soft drinks

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 3, 000–55, 000 l/h

- Pressure differential

- Monitored via pressure transmitters

- Temperature monitoring

- Before and after holding cell

- Energy Savings

- Up to 20%

- Water savings

- Up to 5, 500 l/h

- Booster pumps

- Differential pressure creation

- Automation

- Integrated with operator panel and 21.5” touch screen

- Working Mechanism

- Indirect Heating

- Operation Type

- Aseptic or Hot-fill

- Capacity Range

- 3, 000 l/h to 55, 000 l/h

- Batch vs. Continuous Operation

- Continuous

- Pressure Differential

- Booster pumps with pressure transmitters

- Divert System

- Automatic recirculation on fault

- Automatic Hibernation

- Minimizes energy consumption

- Balance Tank

- Low-loss configuration

- Automation Solution

- Integrated automation software

- Pasteurization Optimization

- Energy savings up to 20%

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Aseptic/Hot-fill Design

- Viscosity

- Handles beverages with fibers and particles

- Foaming

- Sensitive carbonated soft drinks

- Product Variability

- Juices, nectars, still drinks, isotonic beverages

- Container Type

- Ambient temperature storage

- Heat exchanger type

- Tubular / Plate

- Design

- Aseptic / Hot-fill

- Capacity range

- 3, 000–55, 000 l/h

- Interface type

- 21.5” touch screen

- Control panel type

- 21.5” touch screen interface