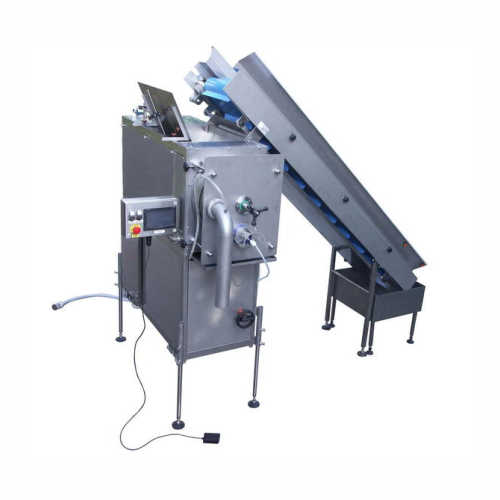

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, stainless steel solution tailored for efficiently dosing and packing sticky products like sauerkraut and kimchi—perfect for ensuring consistent packaging and minimizing product waste.

Fills and Packs Sticky and Granular Products

The stainless steel Dosing and Packing Machine from Kronitek is designed for robust performance in vegetable and fermented food processing. It excels in handling sticky products like sauerkraut and kimchi, offering a seamless integration into your production line with options for conveyors and filling nozzles. Capable of processing various end-products such as pre-packaged salads and shredded cabbages, this machine enhances operational efficiency by automating dosing and packing tasks.

The machine operates at a high throughput, optimizing continuous production with minimal downtime. Its acid-resistant stainless steel construction ensures durability and maintains product quality, offering exceptional corrosion resistance necessary for food processing environments. The equipment is PLC-controlled for precise operation and easy integration with existing systems.

Kronitek provides customization options to meet specific processing requirements, backed by comprehensive engineering support. Built to meet stringent industry standards, it reduces waste and improves profitability, making it an ideal choice for food processors seeking efficient and reliable packing solutions.

Benefits

- Enhances efficiency by automating the packing process, reducing manual labor.

- Minimizes product waste with precise dosing and packing capabilities.

- Offers corrosion resistance, maintaining durability and reliability in harsh food processing environments.

- Seamless integration into existing production lines with customizable attachment options.

- Supports diverse food processing needs, from fermented foods to fresh produce packaging.

- Applications

- Salads, Pet food, Cabbage, Cheese, Apple, Vegetables, Mushrooms, Juice, Sauerkraut, Processed vegetables, Kimchi, Fruit

- End products

- Pre-packaged cheese slices, Shredded and packed cabbage, Pre-sliced apples, Pre-packaged kimchi, Canned mushrooms, Pre-sliced mushrooms, Packaged pet food vegetable mix, Pre-washed and packed salad mixes, Pre-packaged sauerkraut, Bottled apple juice, Packaged apple wedges, Shredded and packed napa cabbage

- Steps before

- Shredding, Conveying, Mixing

- Steps after

- Packing, Jar cup screwing, Labeling

- Input ingredients

- cabbage, napa cabbage, sauerkraut, kimchi, vegetables, salads, processed vegetables

- Output ingredients

- dosed cabbage, packed cabbage, dosed sauerkraut, packed sauerkraut, dosed kimchi, packed kimchi, dosed salads, packed salads, dosed processed vegetables, packed processed vegetables

- Market info

- Material

- Acid-resistant stainless steel

- Residue

- No residue

- Container compatibility

- Jars

- Automation integration

- Conveyors, round tables, filling nozzles

- Automatic screwing capability

- Yes

- Application compatibility

- Sauerkraut, kimchi, cabbage, salads

- Packaging type

- Automatic packaging

- Efficiency improvement

- Less wasteful, more efficient and profitable

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C

- Cleaning method

- CIP / Manual

- Acid-resistant material

- Stainless steel

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Doesn't leave any residue

- Material

- Acid-resistant stainless steel

- Machine Footprint

- Customizable

- Discharge Method

- Conveyor/Nozzle System

- Customization

- Conveyors, Round Tables, Filling Nozzles

- Control Panel Type

- Automatic

- Control panel type

- PLC-based

- Integration possibilities

- Conveyors, round tables, filling nozzles

- Material

- Acid-resistant stainless steel

- Additional equipment integration

- Automatic jar cup screwing machine