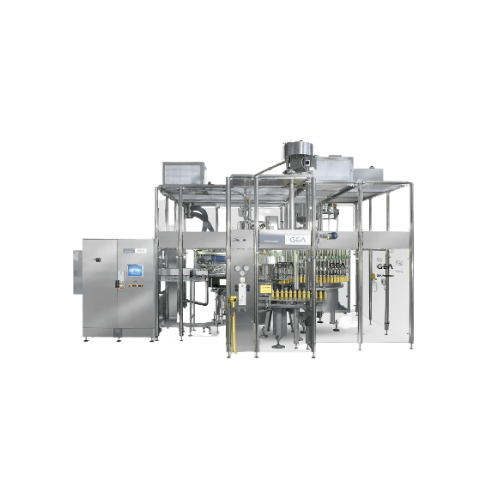

Hot fill gravity filler for beverages

Achieve precise hot filling with versatile gravity filling technology that maintains high temperatures while minimizing product foaming and splash-out, ensuring consistent quality in your juice, lemonade, or plant-based drinks production.

Fills and Sterilizes Beverages with Precision

The Hot Fill Fillstar HF from GEA is a gravity filler tailored for beverage applications, offering precise filling and sterilization capabilities. Featuring versatile filling heads, it adapts effortlessly between brim-full and level filling without tools. Its unique recirculation control minimizes product recirculation to less than 10%, ensuring higher filling temperatures and reducing product splash-out. Ideal for filling fruit juices, flavored water, and plant-based milk, the Fillstar HF operates seamlessly in high-speed, continuous production lines. The system integrates an Advanced Recirculation Control with dual-speed filling to curb turbulence and foaming. With configurations like the Proclean version, it maintains stringent hygiene via laminar flow of sterile air, while the CC version offers advanced contamination control suitable for low acid products. The design includes CIP (Clean-In-Place) for efficient cleaning without the need for dummy bottles, simplified by a spray ball cleaning system for manifolds.

Benefits

- Enhances production efficiency with minimal product recirculation and high-temperature control.

- Reduces operational costs by eliminating the need for dummy bottles during cleaning.

- Maintains high hygiene standards with sterile air flow and contamination control.

- Adapts quickly to different filling requirements without tool changes, supporting versatile production runs.

- Minimizes product loss with dual-speed filling and reduced splash-out, especially in square bottles.

- Applications

- Beverages, Non-alcoholic drinks, Still drinks, Low acid products, Juices, Liquids

- End products

- Lemonade, Iced tea, Plant-based milk, Fruit juices, Flavored water, Non-dairy creamer

- Steps before

- Bottle preparation, Bottle sterilization, Product heating

- Steps after

- Packing, Cooling

- Input ingredients

- bottles, hot liquid products, low acid products

- Output ingredients

- filled bottles, sealed bottles, hot-filled liquid products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Filling method

- Gravity

- Filling volume

- Brim-full / Level filling

- Product recirculation rate

- Less than 10%

- Time opening phase

- High temperature maintenance

- Filling speed

- Dual speed

- Hot fill temperature

- High

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP - Closed loop cleaning

- Changeover time

- Quick tool-free changeover

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- High temperature resistance

- Foaming

- Minimized through dual speed filling

- Container Type

- Square plastic bottles

- Filling Method

- Level or brim-full filling

- Viscosity

- Suitable for liquid applications

- Cleaning Method

- CIP without dummy bottles

- Container Size

- Diverse, adaptable filling head

- Filler Design

- Fillstar HF Carrousel

- Machine Footprint

- Compact design

- Filling Valve Type

- Gravity filling valve HF RCP

- Recirculation System

- Advanced Recirculation Control

- Cleaning System

- No dummy bottles required for CIP

- Contact Zone Design

- Ensures proper cleaning flow rate

- Filling head

- Brim-full / level filling

- Recirculation rate control

- Advanced Recirculation Control

- Product feeding control

- Adjustable rate and closure

- Cleanability configuration

- CIP without dummy bottles

- Version options

- Proclean, CC version

- Environmental Control

- Laminar flow, microbiological isolator

- Cap and bottle sterilization

- Available in CC version

- Filling unit configuration

- Dual speed filling