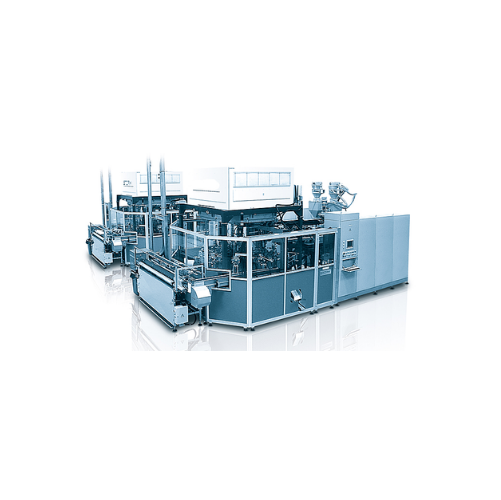

Extrusion blow molder for custom bottles

Enhance your production line by creating versatile and customized bottles with seamless integration, ensuring precise layering for optimal product protection and differentiation in a crowded market.

Forms and Molds Custom Liquid Bottles

The BottleTec™ Extrusion Blow Molder by JBT is a versatile solution for food and beverage manufacturers seeking flexibility in bottle production. It specializes in forming and molding lightweight HDPE bottles for a range of liquids, such as milk, plant-based beverages, juice, and pet food containers. This equipment operates on a continuous, high-speed basis, producing up to 7,500 bottles per hour with precision. The BottleTec™ seamlessly integrates into production lines, offering PLC-controlled operations and the ability to produce up to 15 different bottle designs, facilitating swift design changes. Its extrusion process allows for mono or multi-layer bottles, featuring oxygen and UV-blocking capabilities to protect product integrity. Available in materials resistant to chemical interactions, the system ensures compliance with industry standards while supporting energy-efficient operations. A built-in, easy-to-use CIP system ensures maintenance is straightforward and contamination-free. Additionally, JBT offers comprehensive engineering support to adapt the system to your specific production needs.

Benefits

- Enhances operational efficiency by producing up to 7,500 bottles per hour.

- Lowers production costs with multi-layer bottle options that protect product quality.

- Facilitates rapid design changes for market adaptability, supporting up to 15 bottle designs.

- Ensures product safety through oxygen and UV-blocking layers, preserving product integrity.

- Streamlines maintenance with an integrated CIP system for fast, contamination-free cleaning.

- Applications

- Beverages, Pet food, Dairy alternatives, Coffee, Juices, Tea, Dairy

- End products

- Iced tea bottles, Almond milk bottles, Sports drink bottles, Energy drink bottles, Plant-based milk bottles, Fruit juice bottles, Pet food containers, Beverage cartons, Milk bottles, Cold brew coffee bottles

- Steps before

- Preform preparation, Material blending, Extrusion

- Steps after

- Filling, Labelling, Packaging, Quality inspection

- Input ingredients

- HDPE resin, plastic pellets

- Output ingredients

- HDPE bottles, mono-layer bottles, multi-layer bottles, UV-blocking bottles, oxygen-blocking bottles

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- {{"Technical Specification",Automation,PLC-controlled},{"Technical Specification",Capacity,"7,500 bottles per hour"},{"Technical Specification","Container size range","0.2 to 1.5 liters"},{"Technical Specification","Bottle configurations","Open,closed,sterile-closed"},{"Technical Specification","Layer capability","Mono or multi-layer with oxygen and UV blocking layers"},{"Technical Specification","Bottle design flexibility","4-15 bottle designs"},{"Technical Specification","Material type",HDPE}}

- Versatility

- Bottles in various shapes and sizes

- Production Rate

- Up to 7, 500 bottles/hour

- Production Flexibility

- Open, closed, and sterile-closed bottles

- Capacity Range

- 0.2 liters to 1.5 liters

- Layer Options

- Mono- and multi-layer bottles

- Protection Features

- Oxygen and UV-blocking layers

- Conversion Flexibility

- 4-15 bottle designs

- Changeover Time

- Easy conversion

- Cost Efficiency

- Reduces labor and costs

- Automation Level

- PLC-controlled

- {{"Material Compatibility","Heat resistance",HDPE},{"Material Compatibility",UV-blocking,Available},{"Material Compatibility",Oxygen-blocking,Available},{"Material Compatibility","Corrosive resistance",Yes},{"Material Compatibility","Lightweight material",HDPE}}

- Bottle production type

- Open, closed, sterile-closed

- Bottle shape versatility

- Customizable

- Bottle size range

- 0.2 liters to 1.5 liters

- Bottle design customization

- 4-15 bottle designs

- Bottle size range

- 0.2 liters to 1.5 liters

- Production Configuration

- Open, closed, and sterile-closed bottle production

- Layer options

- Mono- or multi-layer bottles with oxygen and UV blocking layers

- Carousel capacity

- 4-15 bottle designs

- Design flexibility

- Produce bottles of nearly any shape