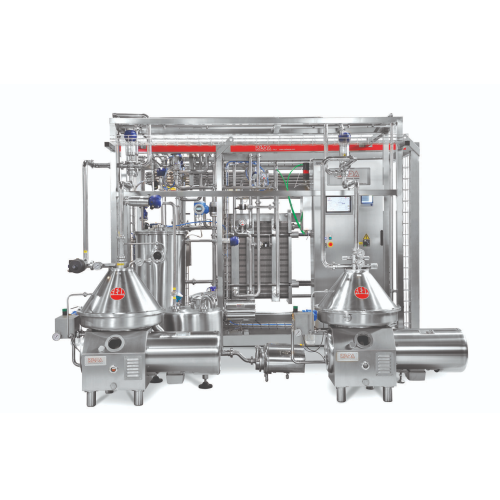

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reducing bacterial load while preserving freshness and nutritional value for a wide range of dairy and beverage applications.

Pasteurizes and Clarifies Liquid Food Products

The Milk Pasteurizer for Whey and Cream from Reda Spa offers an adaptable solution for dairy and beverage producers requiring precise pasteurization of a wide range of liquid food products. Designed with both plate and tubular heat exchangers, this equipment ensures optimal heat transfer, maintaining the taste and nutritional values of products like whole milk, cream cheese, and plant-based drinks. Its skid-mounted, plug-and-play design facilitates easy installation and integration into existing production lines, making it highly versatile for applications in milk, juice, and cheese production. Capable of operating in continuous, semi-automatic, and automatic modes, it provides flexibility across processing environments. This pasteurizer can be configured to incorporate advanced automation with a user-friendly interface, reducing downtime and operational errors. Built with options for stainless steel construction, it resists corrosion and meets stringent food safety standards, ensuring long-term reliability and compliance with industry regulations. Additionally, the system supports clean-in-place (CIP) procedures for efficient maintenance, minimizing contamination risks. Customization options are available to match specific processing capacities and production requirements, backed by Reda Spa’s engineering support.

Benefits

- Enhances product quality by preserving nutritional values and taste during pasteurization.

- Streamlines installation with its plug-and-play skid design, integrating smoothly into existing setups.

- Increases operational efficiency with flexible automation options, accommodating various production scales.

- Minimizes contamination risk through effective clean-in-place (CIP) procedures.

- Offers robust corrosion resistance with stainless steel construction for long-lasting reliability.

- Applications

- Cream, Special products, Liquid food, Plant-based drinks, Wine, Milk, Fermented products, Cheese, Whey, Juice

- End products

- Plant-based dairy alternatives, Non-alcoholic wine, Coconut milk, Apple juice, Orange juice, Almond milk, Skim milk, Greek yogurt, Cream cheese, Soy milk, Whey protein concentrate, Oat milk, Fermented milk drinks, Herbal extracts, Whole milk

- Steps before

- Clarification, Separation

- Steps after

- Concentration, Membrane Concentration, Sterilization, Aseptic Tank, Juice Clarification, Fermentation

- Input ingredients

- whey, cream, milk

- Output ingredients

- pasteurized whey, pasteurized cream, pasteurized milk

- Market info

- Automation

- Total or semi-automatic

- Heat Exchangers

- Plates or tubular

- Installation Type

- Skid-mounted

- Thermal Regeneration

- High

- Production Autonomy

- Longer

- User-friendliness

- User-friendly

- Automation level

- Manual / Semi-automatic / Fully automatic

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- Optimized heat exchange

- Installation type

- Skid-mounted / Plug-and-Play

- Control panel type

- Semi-automatic / Total automatic

- Heat exchanger type

- Plates / Tubular

- Installation type

- Skid-mounted / Plug-and-play

- Integration possibilities

- Advanced automation techniques

- Flexibility

- Maximum performance optimization