Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed filling solution that ensures precise, continuous filling for liquid products, from beverages to thick sauces, while minimizing downtime and enhancing process flexibility.

Fills and Seals Liquid Bag-in-Box Packages

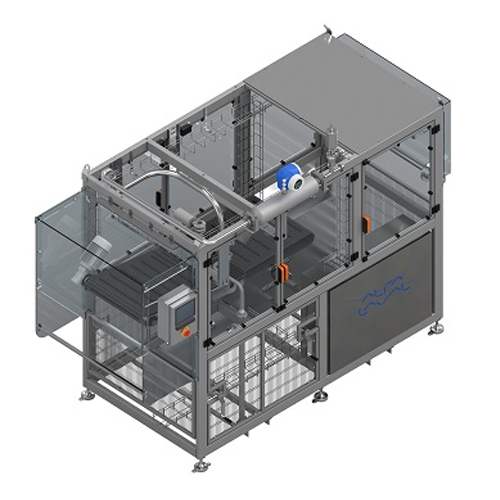

The Astepo Grande Filler from Alfa Laval is an automated bag-in-box filling machine designed for a range of liquid products, offering a seamless integration into high-speed production lines. Known for its versatility, this machine efficiently handles capacities from 2 to 20 liters with a throughput of up to 700 bags per hour. The system operates by uncapping, filling, and capping bags via a pneumatic mechanism, ensuring rapid changeovers and precise filling with an accuracy of ±0.5%. Applications span from beverages and sauces to non-food products, supporting industries like food and beverage production and sauce manufacturing. The Astepo Grande Filler distinguishes itself with its optional pre-filling vacuum and post-filling nitrogen puff features, enhancing product preservation. Built for continuous operation, it minimizes downtime with easy-to-execute cleaning-in-place (CIP) and maintenance routines, bolstered by a global network for customer support. The machine’s adaptability to different bag sizes and cap types further enhances its role in diverse packaging environments.

Benefits

- Enhances production efficiency with rapid changeovers and high filling speeds.

- Minimizes product loss and downtime through precise bag handling and sealing.

- Supports operational flexibility with easy adaptation to various bag sizes and cap types.

- Ensures product integrity and extends shelf life by preventing oxygen exposure.

- Simplifies maintenance and cleaning with integrated cleaning-in-place (CIP) capabilities.

- Applications

- Beverages, Liquid food, Post-mix products, Shelf-stable products, Wine, Non-food products, Liquid dairy, Syrups, Vegetable oils, Thick sauces

- End products

- Cola concentrate, Ketchup, Olive oil, Uht milk, Canned soup, Red wine, Almond milk, Maple syrup, Fruit juices, Cleaning detergents

- Steps before

- Sterilization, Aseptic storage, Vacuum pre-filling

- Steps after

- Packing, Shelf life extension, Nitrogen post-filling

- Input ingredients

- wine, beverages, thick sauces, post-mix products, syrups, vegetable oils, shelf-stable products, liquid food, liquid non-food products

- Output ingredients

- filled bags, sealed bags, bagged liquids, bag-in-box packaging

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Filling accuracy

- ±0.5%

- Filling speed

- Up to 700 bags/hour

- Bag size

- 2–20 litres

- Automation

- Automated operation

- Cap type

- Caps, spouts, dispenser taps

- Changeover

- Efficient changeover between bag sizes, closures

- Cleaning method

- Cleaning-in-place (CIP)

- Flow control

- Optional mass flow meter

- Pneumatic system

- Pneumatic system for bag feeding

- Pneumatic cylinder

- Cap removal synchronized with filling valve

- Working mechanism

- Automatic bag uncap-fill-cap

- Integrated steps

- Uncaps, fills, caps

- Batch vs. continuous operation

- Batch

- Automation level

- Fully Automated

- Changeover time

- Quick changeover between bag sizes and closures

- CIP/SIP

- Minimizes downtime with CIP

- Cleaning method

- CIP

- Air incorporation control

- Prevents oxygen pick-up

- Production speed

- Up to 700 bags per hour

- Biological compatibility

- Yes

- Cleanability

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bag size

- 2–20 litres

- Bag type

- Web bags with front-mounted caps

- Cap type

- Caps, spouts, dispenser taps

- Machine footprint

- Compact

- Output capacity

- Up to 700 bags per hour

- Cleaning cycle adaptability

- Adjustable

- Changeover capability

- Efficient changeover between bag sizes and closures

- Bag size compatibility

- 2–20 litres

- Cap type compatibility

- Front-mounted caps, spouts, dispenser taps

- Changeover capability

- Quick and easy swap between bag sizes and closures

- Filling method customization

- Pre-filling vacuum, post-filling nitrogen puff, HEPA filter

- Pneumatic system integration

- Automatic bag feeding, cap removal synchronization

- Control panel/HMI type

- Automated operation

- Integration possibilities

- Mass flow meter for accurate filling