Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with our pneumatic hammers, designed to prevent blockages and ensure smooth discharging in bulk solids handling systems. Ideal for processes where powder compaction or bridging can hinder performance.

Enhances Material Flow and Prevents Blockages

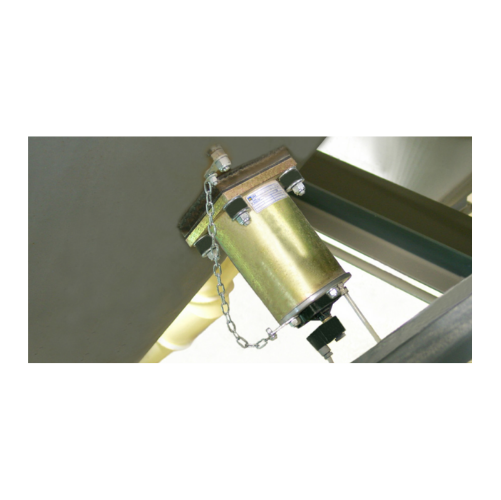

The MARTSHOCK PS Single Impact Pneumatic Hammer from WAMGROUP is engineered to enhance material flow in various industrial setups by delivering a powerful shockwave that dislodges compacted or bridged materials. Its robust design integrates an internal piston that impacts a metallic base, effectively preventing issues like rat-holing in silos and hoppers. This equipment excels in industries such as ready-mix concrete, flour milling, and cocoa processing, ensuring smooth discharging of high-density powders and bulk solids. Operating with pressures ranging from 3 to 6 bar, the hammer is particularly suitable for retrofitting without requiring drilling or permanent structural changes. Available in three sizes, it offers flexibility for integration into existing systems. Designed for both indoor and outdoor applications, its galvanized steel and POM construction ensures durability and resistance to environmental factors. The MARTSHOCK PS is ATEX-compliant, making it safe for potentially explosive environments, while its optional noise reduction and timing kits enhance operational control. Easy installation and maintenance are facilitated by a pre-welded mounting plate and a safety chain, providing reliability in continuous industrial operations.

Benefits

- Improves material flow and reduces downtime by preventing blockages and compaction.

- Suitable for explosive environments, ensuring operational safety with ATEX compliance.

- Offers easy integration and retrofitting without structural modifications, minimizing installation costs.

- Durable design withstands harsh conditions, increasing equipment lifespan and reliability.

- Customizable operation with pressure and timing adjustments for tailored performance.

- Applications

- Sugar processing, Ready-mix concrete production, Rubber processing, Biscuit processing, Drymix building materials, Paint processing, Animal feed milling, Pharmaceuticals processing, Plastics processing, Brewery plants, Cosmetics processing, Iron and steel mills, Dust filtration plants, Flour milling, Chocolate processing, Spices, Rice milling, Glass processing, Cocoa, Coffee processing, Seed processing, Convenience food, Detergent processing, Oil, Resin processing, Varnish processing, Soap processing, Winery plants, Precast concrete production, Petfood, Bakeries, Fish food, Salt processing, Power plants (fly-ash handling), Fertilizer processing

- End products

- Biscuits, Pelleted animal feed, Concrete mix, Precast concrete blocks, Wheat flour, Skincare products, Beer, Rubber tires, Laundry detergent, Cocoa powder, Pharmaceutical tablets, Wine, Steel beams, Filtered air, Epoxy resin, Kibble, Glass sheets, Milled rice, Fish pellets, Paint coatings, Packaged spices, Processed seeds, Olive oil, Varnish, Granulated sugar, Fly ash bricks, Ground coffee, Fertilizer granules, Baked goods, Table salt, Plastic components, Chocolate bars, Soap bars, Dry mortar

- Steps before

- Purification, Drying, Grinding

- Steps after

- Bulk Solids Packaging, Transporting, Storage

- Input ingredients

- bulk solids, powder, compressed air

- Output ingredients

- discharged solids, resolved material flow issues, reduced bridging, reduced rat-holing

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Operation pressure

- 3 to 6 bar (44 ~ 87 PSI)

- Material

- Galvanized Steel

- Compatibility

- Outdoor/Indoor applications

- Sizes available

- Three different sizes

- Noise reduction

- ATEX KIT plate (ATEX II3D cT(x))

- Automation

- Fully pneumatic kit with Timer

- Impact type

- Single Impact

- Installation

- Mounting plate with safety chain

- Timer

- Minimum 30 sec

- Coils voltages

- 24 V DC/AC to 230 V (ATEX)

- Application

- Retrofitting existing cones or hoppers

- Customization

- Compact design with integrated valve

- Environmental Compliance

- ATEX-compliant

- Working Mechanism

- Single Impact Pneumatic

- Air Pressure Range

- 3 to 6 bar (44 ~ 87 PSI)

- Application Location

- Indoor/Outdoor

- Intermittent Operation

- Yes

- Sequential Activation

- Bottom to Top

- Explosion Safety

- ATEX-compliant

- Installation Requirement

- No Drilling Required

- Size Options

- 3 Sizes Available

- Safety Features

- Safety Chain

- Suitability

- Hoppers and Cones

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Retrofitting existing cones or hoppers

- Yes

- Use in Bulk Solids Discharging

- Yes

- Design

- Robust, suitable for outdoor and indoor application

- Material

- Galvanized steel, POM

- Size Options

- Three different sizes available

- Mounting Method

- Supplied with a mounting plate to be welded

- Safety Features

- Safety chain to prevent accidental dropping

- Control Options

- Timer to adjust period of blast

- Mounting Plate

- Welded on the wall

- Noise Reduction Kit

- Yes

- Material

- Galvanized steel, POM

- Safety Chain

- Prevents accidental dropping

- Pneumatic Kit

- Fully pneumatic available