Ultrafiltration module for high-viscosity products

Achieve enhanced separation efficiency with a versatile module designed for ultrafiltration and microfiltration, optimizing flow dynamics and reducing energy consumption for high-viscosity products.

Filters and Separates High-Viscosity Liquids and Slurries

The Module M39L/H from Alfa Laval is a premier plate-and-frame filtration unit designed for intricate filtration tasks across biotech, pharmaceutical, and food industries. Its unique design with interchangeable flat sheet ultrafiltration and microfiltration membranes provides exceptional efficiency in separating, concentrating, and purifying high-viscosity liquids and fermentation broths. Operating under low pressure with temperatures up to 80°C and a pH range of 1-14, this module offers reduced energy consumption by up to 30% and increased flux by 30% compared to previous models.

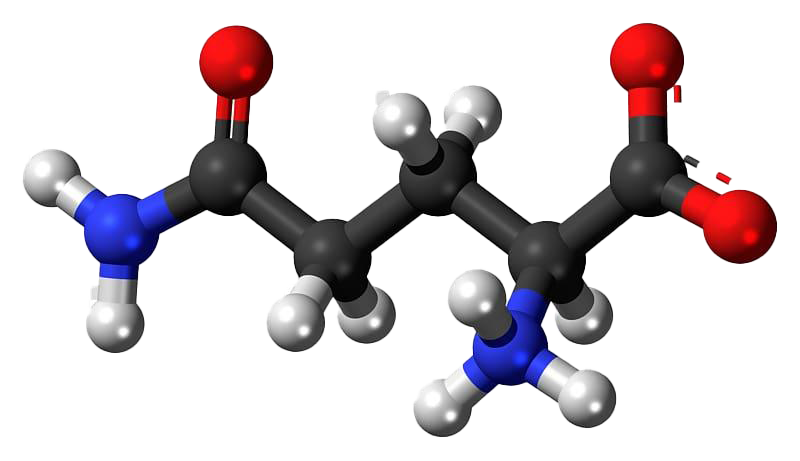

The M39L/H is specifically engineered to manage applications involving antibiotics, amino acids, and fermentation processes, producing high-quality end-products such as cephalosporin, xanthan gum, and lactose-free milk. The module’s modular and flexible design allows seamless integration into continuous operation systems, ensuring scalability with production growth needs.

Fabricated for durability, its channels are customizable for low or high flow demands and available in standard sizes with membrane areas up to 60 m². Alfa Laval’s unit conforms to stringent industry standards, featuring easy membrane replacements and a reduction in operational pressure by approximately 1.5 times, contributing to lower overall system costs by 10-30%. Equipped with an intuitive design, it provides reliable performance with simplified cleaning and maintenance, ensuring minimal downtime in high-demand environments.

Benefits

- Lowers operational costs with up to 30% energy reduction.

- Increases production efficiency with 30% higher flux.

- Reduces maintenance time through easy membrane replacement.

- Customizable design supports scalable production growth.

- Enhances product purity with precise separation capabilities.

- Applications

- Food, Amino acids, Fermentation broths, Sugar, Beverage, Antibiotics, Organic acids, Gums, Biotech, Dextrans, Dairy, Pharmaceuticals

- End products

- Lactic acid, Lactic fermentation broth, Sucrose, Xanthan gum, Tryptophan, Glutamic acid, Fructose, Whey protein concentrate, Beer filtration, Wine clarification, Lactose-free milk, Dextranase, Erythromycin, Citric acid, Cephalosporin

- Steps before

- Fermentation, Mixing, Cooling

- Steps after

- Concentration, Purification, Separation

- Input ingredients

- high-viscous products, fermentation broths, antibiotics, amino acids, organic acids, dextrans, industrial fermentation, dairy, gums, sugar

- Output ingredients

- concentrated liquids, purified liquids, separated low molecular-weight substances

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Viscosity Range

- 1-30 cP

- Operating Temperature

- up to 80°C

- Operating Pressure

- up to max. 8 bar

- PH Range

- 1-14

- Membrane Area

- up to max. 60 m²

- Flux Increase

- up to 30%

- Energy Consumption Reduction

- up to 30%

- Module Size Increase

- approx. 1.5 times bigger

- Concentration Degree Increase

- up to 15%

- Operation Pressure Reduction

- approx. 1.5 times reduction

- Working mechanism

- Plate-and-frame module

- Flow dynamics

- Optimized for low energy consumption

- Concentration and separation

- Ultrafiltration and microfiltration

- Batch vs. continuous operation

- Batch / Inline Continuous

- Temperature operation range

- Up to 80°C

- Pressure operation range

- Up to 8 bar

- PH operation range

- 1-14

- Channel size options

- Low (L) or High (H)

- Membrane replacement

- Individual replacement without affecting others

- Flexibility

- Modular and expandable design

- Corrosive resistance (e.g. acids)

- pH 1-14

- Filtration Type

- Ultrafiltration / Microfiltration

- Applications

- Biotech, Pharma, Food, Beverage

- Product Types Processed

- Antibiotics, Amino Acids, Fermentation Broths

- Discharge method

- Open channel flow

- Plate Channel Type

- Low (L) / High (H)

- Membrane Type

- Microfiltration (MF) / Ultrafiltration (UF)

- Membrane Area

- Up to 60 m²

- Temperature Range

- Up to 80°C

- Pressure Range

- Up to 8 bar

- PH Range

- 1-14