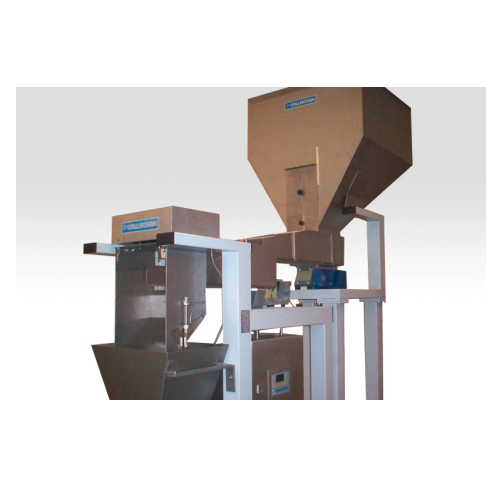

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantities with advanced weighing and dosing capabilities, ensuring high-speed accuracy even for demanding production environments.

Weighs and Fills Bulk Powders and Granules

The S720 Weigh Filler from Collischan GmbH is engineered to meet the demands of industries dealing with bulk powders and granules. Utilizing a dual vibrating chute system, the S720 achieves high precision in large-scale dosing, ideal for products like powdered milk, instant coffee, and pharmaceutical tablets. Capable of processing weights from 2 to 20 kg with a remarkable resolution of 10 mg, it ensures accuracy and minimal waste. Its modular design allows for customization to fit specific production requirements, offering integration into complete packaging lines with external synchronization options. Made from stainless steel, the S720 is easy to clean, supporting hygiene and efficiency with tool-free disassembly for rapid sterilization. This machine complies with explosive-proof standards, suitable for hazardous environments within chemical and automotive industries. With adaptive digital control, it optimizes vibration feeder speeds and provides real-time data feedback, including standard deviation and mean values.

Benefits

- Enhances accuracy in bulk filling, reducing material waste through 10 mg resolution precision.

- Simplifies cleaning and maintenance with easy-to-remove, tool-free components.

- Adapts to specific production needs with customizable modular design.

- Increases safety in hazardous environments with compliant explosive-proof construction.

- Integrates seamlessly into existing lines for efficient, synchronized operations.

- Applications

- Chemistry, Automotive, Coffee, Food industry, Powder and granules, Explosive material, Spices, Sweets and drops, Pharma industry, Tablets, Tea, Capsules

- End products

- Powdered milk, Gelatin capsules, Cocoa powder, Herbal tea blends, Pharmaceutical tablets, Paprika powder, Granulated sugar, Firework powder, Jelly beans, Automotive airbag deployers, Effervescent tablets, Instant coffee granules

- Steps before

- Product preparation, Vibrating chute setup, Parameter configuration

- Steps after

- Packing, Filling, External synchronization

- Input ingredients

- big quantities, 2 to 20kg products, powder, granules, spices, tea, coffee, sweets, drops, tablets, capsules, explosive material

- Output ingredients

- weighed products, filled containers, batches, 30 fillings per minute

- Market info

- Weight Capacity

- 2 to 20 kg

- Resolution

- 10 mg for 10 kg

- Performance Speed

- 30 fillings per minute

- Control System

- Digital adaptive control algorithm

- Dosing Type

- Rough and fine dosing

- Material

- Stainless steel

- Ex-Proof Design Zones

- 0, 1, 2 and 20, 21, 22

- Temperature Range

- Up to T6

- Synchronization

- External and internal synchronization

- Statistics Feature

- Standard statistics counter, mean value, standard deviation

- Working mechanism

- Vibrating chutes

- Automation level

- Digital adaptive control algorithm

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual removable without tools

- Ex-proof certification

- Zones 0, 1, 2, 20, 21, 22

- Synchronization

- External and internal synchronization

- Weight range

- 2 to 20 kg

- Filling speed

- 30 fillings per minute

- Corrosive resistance (e.g. acids)

- Stainless steel

- Cleanability

- Tool-free disassembly

- Density/particle size

- Compatible with 0.5–2.5 g/cm³ / 50–1000 µm

- Hygienic design

- Manufactured exclusively from stainless steel

- Explosive material handling

- Yes

- Machine footprint

- Compact or customizable

- Material

- Stainless steel

- Modular setup

- Available

- Discharge method

- Vibrating chutes

- Weight capacity

- 2 to 20 kg

- Resolution

- 10 mg for large quantities

- Construction materials

- Stainless steel

- Explosive-proof design

- Zones 0, 1, 2, 20, 21, 22

- Modular setup

- Customizable for space and performance