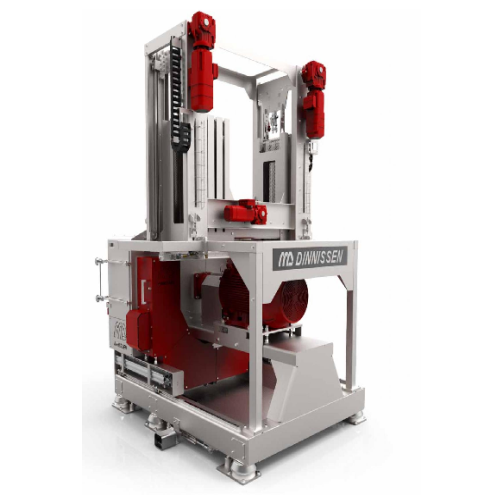

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamless sifter changes, reducing downtime and manpower while maintaining consistent product quality in demanding production environments.

Grinds and Screens Powders and Granules

The Hamex Automatic Screen Exchange Hammer Mill by Dinnissen is an advanced grinding solution for processing grains, sugars, and minerals. It features a fully automated screen exchange system, allowing continuous operation without manual intervention. Capable of handling powders and granules in industries such as food, pharma, and chemicals, it offers adjustable rotor speeds with frequency control for precise grinding outcomes ranging from 150 microns to 3 mm. This hammer mill supports high-speed operation up to 1800 rpm while maintaining energy efficiency by utilizing a variable-speed motor. It includes options for a stone collector and magnet to enhance product purity, and its robust construction ensures long service life with minimal maintenance.

Benefits

- Minimizes labor costs with a fully automated screen exchange system.

- Enhances energy efficiency through variable-speed motor optimization.

- Allows for quick product changeover with precise frequency control.

- Ensures product purity by separating contaminants with optional collectors.

- Promotes long service life with durable construction and easy maintenance.

- Applications

- Food, Grains, Chemicals, Feed, Pet food, Sugars, Pharma, Minerals, Aquafeed

- End products

- Detergent powders, Cornflakes, Mineral powders, Granulated sugar, Salt blocks, Flour, Poultry feed, Fish feed pellets, Fish meal, Antibiotic powders

- Steps before

- Intake, Conveying, Feeding

- Steps after

- Sifting, Screening, Packaging

- Input ingredients

- grains, sugars, minerals, soft products, medium-hard products

- Output ingredients

- fine grind, coarse grind, particles with correct fineness

- Market info

- Dinnissen is renowned for its expertise in process technology, specializing in innovative solutions for powder handling, mixing, and bulk materials processing for various industries, including food, feed, and chemicals, with a reputation for quality and custom engineered solutions.

- Grinding Speed

- Up to 1800 rpm

- Fineness Range

- 150 microns to 3 mm

- Automation

- Fully automatic sifter exchange

- Energy Efficiency

- Energy-efficient operation

- Noise Level

- Minimal noise

- Frequency Control

- Available

- Direction of Rotation

- Variable

- Tip Speed

- Consistent

- Material Type

- Soft to medium-hard products

- Capacity

- Increased production capacity

- Contamination Prevention

- Stone collector and magnet

- Working Mechanism

- Freely suspended hammers with centrifugal force

- Integrated Steps

- A fully automatic sifter changing system

- Automation Level

- PLC-controlled with frequency control

- Changeover Time

- Up to ten minutes saved per sifter change

- Noise Level

- Minimal noise level without affecting grinding speed

- Energy Efficiency

- Low energy consumption with a maximum speed of 1800 rpm

- Batch vs. Continuous Operation

- Continuous

- Adjustable Rotor Speed

- Frequency control allows fine/coarse switching

- Material Processing Range

- Soft to medium-hard products

- Particle Size Range

- 150 microns to 3 mm

- Soft material compatibility

- Grains, sugars

- Medium-hard material compatibility

- Minerals

- Particle size adaptability

- 150 microns to 3 mm

- Ferrous particle separation

- Magnet and stone collector

- Machine Footprint

- Variable

- Design

- Compact and robust construction

- Accessibility

- Good accessibility for maintenance

- Sifter Type

- Automatic Screen Exchange

- Rotation Speed

- Up to 1800 rpm

- Rotor Type

- Variable direction of rotation

- Noise Level

- Minimal

- Material Discharge

- Continuous

- Built-in Systems

- Frequency control and airflow system

- Separation Mechanism

- Stone collector and magnet

- Control Panel Type

- HMI / PLC

- Frequency Control

- Variable / Adjustable Speed

- Automatic Sifter Change System

- Yes

- Stone Collector and Magnet

- Yes

- Airflow System

- Customizable