Bin level indicators for powder and granular material

Ensure precise inventory management and prevent overflows in your processing operations with this advanced vibration measurement technology, designed for straightforward integration into existing bins or silos handling powders and granular materials.

Monitors and Signals Material Levels in Bins

The ILV Bin Level Indicators from WAMGROUP are designed for precise level measurement in a wide range of industries, including food processing and chemicals. Utilizing fork vibration technology, they provide accurate electric signaling for minimum or maximum material levels in bins, hoppers, and silos. The ILV indicators are highly versatile, accommodating powders and granular materials with ease, and offer exceptional durability with stainless steel contact parts. They are engineered to maintain process stability and safety, with multivoltage design options suitable for high or low temperature environments. Available in ATEX versions for dust explosion zones 20/21, the ILVs ensure compliance with safety regulations. Installation and replacement are straightforward, minimizing downtime. With extendable probes reaching up to 20 meters, these maintenance-free indicators integrate seamlessly into existing monitoring systems, making them indispensable for consistent and reliable level detection in diverse operational settings.

Benefits

- Ensures operational safety by preventing material overflows with precise level monitoring.

- Increases efficiency with quick installation and easy replacement.

- Enhances durability and hygiene with stainless steel parts, preventing contamination.

- Supports challenging environments with high or low temperature options and ATEX compliance.

- Minimizes maintenance costs with a robust, maintenance-free design.

- Applications

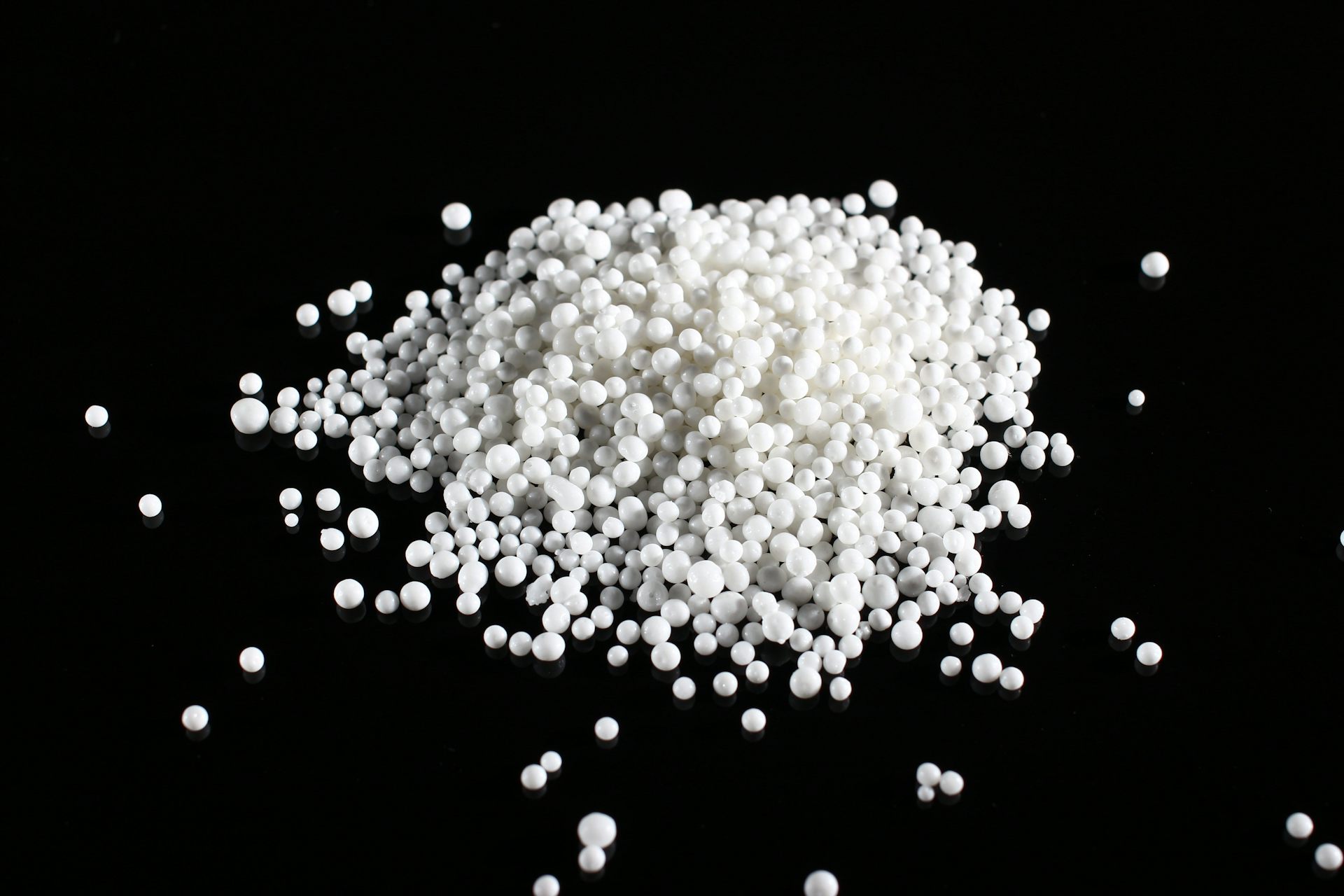

- Food, Chemicals, Lime, Feed, Insecticides, Granular materials, Glass, Pesticides, Plastics, Powders, Fly-ash, Fertilizers

- End products

- Chemical powders, Insecticide pellets, Instant drink powders, Ammonium nitrate, Granulated sugar, Hydrated lime, Ground glass, Flour, Fly-ash cement, Animal feed pellets, Herbicide granules, Bakery flour, Plastic pellets

- Steps before

- Bulk Solids Conveying, Bulk Solids Feeding, Metering, Mixing

- Steps after

- Packing, Biscuit Processing, Silo Safety System

- Input ingredients

- powders, granular materials, very light bulk solids

- Output ingredients

- level signal

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Fork Material

- 304 Stainless Steel

- Process Temperature Options

- High / Low

- Measuring Range

- Up to 20 meters (22 yds)

- Extendibility

- Up to 4 meters (4.4 yds)

- Explosion Protection

- ATEX version, zone 20 / 21

- Multivoltage Design

- Yes

- Installation Type

- Quick installation and replacement

- Working mechanism

- Fork vibration signalling

- Installation

- Quick installation and replacement

- Maintenance

- Maintenance-free

- Automation level

- Multivoltage design

- Environmental safety

- ATEX version for zone 20 / 21

- Density/particle size

- Very light bulk solids

- Corrosive resistance (e.g. acids)

- 304 stainless steel

- Cleanability

- Maintenance-free

- Abrasion resistance

- Stainless steel components

- ATEX certification

- Zone 20 / 21

- Probe length

- Up to 4 metres (4.4 yds) for ILVB, up to 20 metres (22 yds) for ILVC

- Material composition

- 304 stainless steel forks and fittings

- Installation method

- Quick installation and replacement

- Device type

- Electric signalling by fork vibration

- Design type

- Multivoltage design

- Extendibility

- Up to 4 meters (ILVB), up to 20 meters (ILVC)

- Explosion Proof Options

- Available for specific models