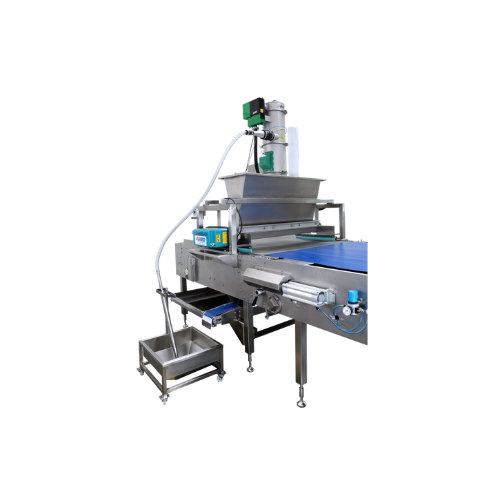

Vibration sprinkler for uniform dough decoration

Elevate your baked goods with precise, uniform decoration using a vibration sprinkler designed for consistent distribution of toppings like salt, sugar, or seeds, enhancing both appearance and quality.

Uniformly Distributes Sprinkles on Baked Goods

The Meincke VSV Vibration Sprinkler by Bühler Group offers precise decoration solutions for the bakery and confectionery industry. Designed to uniformly distribute sprinkles on baked goods like cookies, cakes, and pretzels, it uses a vibratory slide system with manual density adjustment. This equipment adapts to various standard working widths, accommodating production capacities with a storage tank ranging from 74 to 150 liters. Ideal for continuous or manual operations, it efficiently decorates products with non-greasy granules, enhancing consistency and reducing waste. Its robust construction ensures durability, while Bühler’s engineering support provides customization to meet specific production line needs.

Benefits

- Enhances product quality with precise and uniform sprinkle distribution.

- Reduces material waste by enabling re-use of excess sprinkles.

- Adapts to various production capacities with adjustable working width compatibility.

- Optimizes manual control, allowing fine-tuning for specific operational needs.

- Minimizes operational disturbances with straightforward integration into existing lines.

- Applications

- Biscuits, Cakes, Baked goods, Snacks

- End products

- Layered cakes, Cookies, Bread rolls, Crackers, Croissants, Sugar-coated pastries, Pretzels, Salted biscuits, Pound cake

- Steps before

- Dough preparation, Extrusion, Shaping

- Steps after

- Cooling, Buffering, Packing, Palletizing

- Input ingredients

- dough blanks, dry non-greasy material, salt, sugar, poppy seeds

- Output ingredients

- decorated dough blanks

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Sprinkling material size

- Uniform grain size

- Storage tank volume

- 74–150 liters

- Working width compatibility

- All standard working widths

- Vibratory frequency

- Adjustable

- Sprinkle density control

- Manual adjustment

- Sprinkling material adjustment

- Manual

- Sprinkling uniformity

- Controlled by vibratory frequency

- Working width adaptability

- Standard working widths

- Storage capacity

- 74-150 liters

- Automation level

- Manual adjustments

- Changeover time

- Quick due to adjustable slide and frequency

- Cleanability

- Yes

- Density/particle size

- Uniform grain size

- Decorative Sprinkling Materials

- Non-greasy, uniform grain size

- Tank size

- 74–150 liters

- Discharge method

- Vibratory

- Control panel type

- Manual adjustment available

- Integration possibilities

- Fits all standard working widths

- Storage tank capacity

- 74–150 liters

- Sprinkling density control

- Manual via slide inclination and vibratory frequency