Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our innovative vibrators, designed to deliver consistent shockwaves that keep your bulk powders and slurries moving efficiently through your process line.

Prevents Bridging and Enhances Material Flow

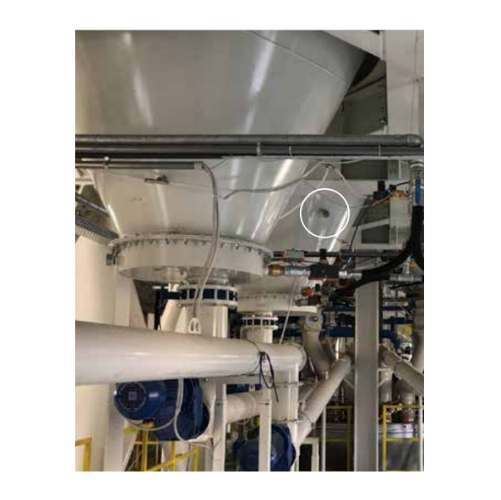

The P-Series Continuous Impact Vibrators from WAMGROUP provide a robust solution for ensuring reliable material flow in various challenging environments. These vibrators work by delivering continuous shockwaves through the impact of an internal piston, effectively preventing bridging, incrustation, and rat-holing in bulk materials. Designed for continuous operation, they are versatile enough for use in high-temperature conditions up to 200 °C (390 °F) and can handle an array of materials ranging from clay and sludge to delicate food and pharmaceutical powders.

The P-Series is particularly beneficial in industries such as construction, food processing, and heavy industries where materials often adhere to equipment surfaces. The vibrators feature a compact design and high-performance capability, are ATEX-certified for use in potentially explosive environments, and are easy to install by welding onto base plates. To further enhance operational safety and maintenance ease, a safety chain is recommended during installation.

Available in three sizes, these vibrators boast a pressure operation range of 2 to 6 bar (29 to 87 PSI), providing flexibility to meet specific process requirements. With their aluminum and powder-coated grey cast iron construction, the P-Series is engineered to withstand abrasive materials, ensuring long-lasting performance and reduced maintenance needs. Whether used independently or in conjunction with other flow aids such as aeration pads and pneumatic hammers, these vibrators provide comprehensive material handling solutions across diverse industrial applications.

Benefits

- Enhances material flow and minimizes blockage risks with continuous shockwave application.

- Supports high-temperature operations, boosting versatility in demanding environments.

- Reduces maintenance with robust, corrosion-resistant construction.

- Increases safety in hazardous settings through ATEX compliance.

- Offers flexible integration options with various size configurations.

- Applications

- Lime, Steel, Pesticide, Cosmetics, Sludge, Soap, Seed, Minerals, Bakery products, Chocolate, Cement, Wine, Insecticide, Glass, Spices, Rubber, Resin, Cocoa, Animal feed, Cokes, Pasta, Noodle, Sugar, Convenience food, Varnish, Oil, Electrostatic powders, Biscuit, Fertilizer, Rice, Plastics, Salt, Foundries, Petfood, Pharmaceuticals, Beverages, Clay, Fish food, Paint, Coffee, Manure, Flour, Detergent, Gypsum, Iron, Refractory products, Distillery products

- End products

- Pottery clay bricks, Biscuits, Steel billets, Livestock feed pellets, Refractory bricks, Organic fertilizer pellets, Metallurgical coke, Wheat flour, Parboiled rice, Granular pesticides, Rubber tires, Curry powder, Powder detergent, Polyethylene pellets, Cocoa powder, Pharmaceutical tablets, Bottled wine, Epoxy resin, Ceramic tiles, Kibble, Portland cement, Coffee beans, White lime powder, Iron ore pellets, Treated wastewater sludge pellets, Aquaculture feed, Gypsum board, Olive oil, Granulated sugar, Acrylic paint, Instant soup, Whiskey barrels, Seed oil, Dog treats, Fresh pasta, Liquid soap, Instant noodles, Fertilizer granules, Gloss varnish, Foundry molds, Table salt, Antistatic compound powders, Bottled beverages, Bread loaves, Chocolate bars, Liquid insecticides, Foundation cream, Glass bottles

- Steps before

- Material Mixing, Bulk Solids Transportation, Silo Filling

- Steps after

- Material Discharge, Packaging, Quality Inspection

- Input ingredients

- bulk materials, wet powders, electrostatics powders, clay, sludge, manure

- Output ingredients

- unstuck materials, free-flowing powders, dislodged sludge

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Pressure Range

- 2 to 6 bar (29 ~ 87 PSI)

- Temperature Tolerance

- Up to 200 °C (390 °F)

- Material

- Aluminium, Grey Cast Iron

- Mounting Plate

- Base mounting plate (not supplied)

- Working mechanism

- Continuous Impact

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual / Automatic

- Pressure range

- 2 to 6 bar (29 ~ 87 PSI)

- Temperature resistance

- Up to 200 °C (390 °F)

- Safety features

- Safety chain

- Environment suitability

- Indoor / Outdoor, ATEX-compliant

- Abrasion resistance

- High

- Biological compatibility

- Yes (with agricultural materials like manure)

- Cleanability

- Easy to clean due to robust design

- Corrosive resistance (e.g. acids)

- Suitable

- Density/particle size

- Handles various densities and sizes

- Material types

- Clay, sludge, manure

- Operating Temperature

- Up to 200°C (390°F)

- Body Material

- Aluminum, Powder-coated Grey Cast Iron

- Design

- Robust, Compact

- Safety Chain

- Included

- Pressure Range

- 2 to 6 bar (29 ~ 87 PSI)

- Mounting

- Base Mounting Plate (welded)

- Explosion Safety

- ATEX-compliant

- Base mounting plate

- Not supplied, must be welded

- Safety chain

- Recommended