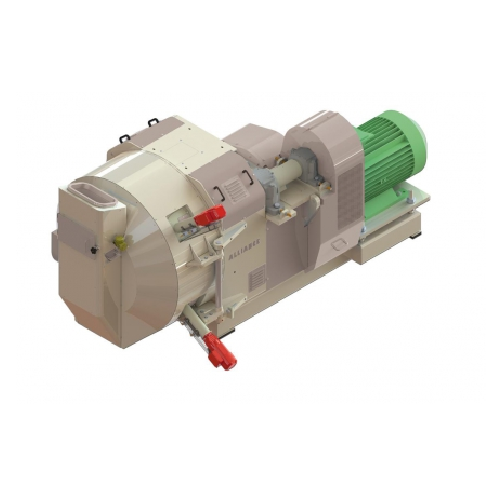

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solution that ensures optimal compression of powdery feedstocks, ideal for continuous and automated operations.

Pellets Powdered Products for Diverse Industries

The Alliance Pellet Mill from Stolz is engineered for efficient pelleting of powdery materials across agribusiness, biofuel, and grain processing sectors. It features a unique double belt transmission allowing modulation of die speed (3.8 to 6.7 m/s), ensuring optimal energy use and adaptation to various products. Ideal for producing pelletized animal feed and wood pellets, the mill integrates seamlessly into automated production lines, offering ultra-slow die speeds and two-way rotation to release products efficiently. With a compact, vibration-reduced design, it simplifies retrofitting existing systems while maintaining low noise and contamination risks. The system includes advanced options like automatic greasing and roller temperature control, enhancing operation reliability and reducing maintenance demands. Available material options ensure compliance with industry safety standards, while its robust engineering promises minimal downtime and long-term operational efficiency.

Benefits

- Enhances productivity with customizable die speeds for diverse material processing.

- Minimizes system downtime with automatic greasing and easy access design.

- Reduces operational noise, ensuring a quieter workspace and improved safety.

- Supports seamless integration into existing lines, simplifying updates and retrofits.

- Limits contamination risk through efficient grease recovery and controlled feeding systems.

- Applications

- Agrofood, Cocoa, Oilseeds, Port silos, Animal nutrition, Cereals, Grain silos, Mash, Rice, Flours, Biofuel

- End products

- Polished rice, Cocoa powder, Cornflakes, Wood pellets, Wheat flour, Stored wheat, Cooking oil, Soy protein meal, Pelletized animal feed, Bulk stored grain

- Steps before

- Grinding, Raw material feeding, Mixing, Drying

- Steps after

- Cooling, Pellet coating, Packing, Storage

- Input ingredients

- powdery products, cereals, flours, mash, cocoa, rice

- Output ingredients

- pellets, compressed products

- Market info

- Stolz is known for its expertise in designing and manufacturing industrial machinery and equipment, particularly for the agricultural sector, including animal feed, grain processing, and bulk materials handling systems. They have a strong reputation for quality and innovation.

- Transmission type

- Double set of belts

- Die speed range

- 3.8 to 6.7 m/s

- Vibration level

- Restricted

- Construction height

- Compact

- Noise level

- Low

- Contamination risk

- Limited

- Cleaning process

- Easy and limited

- Rollers and die system size

- Largely sized

- Two-way die rotation

- Available

- Ultra low speed

- 1 rpm with strong torque

- Automatic greasing

- Included

- Rollers temperature control

- Available (optional)

- Forced feeding

- By screw (optional)

- Motorized pellet knives

- Available (optional)

- Heated door

- Available (optional)

- Meals and steam feeding regulation

- Available (optional)

- Transmission type

- Double set of belts

- Die speed modulation

- 3.8 to 6.7 m/s

- Vibration level

- Restricted

- Noise level

- Low

- Contamination risk

- Limited

- Cleaning method

- Easy and limited

- Shock absorption

- Yes, in case of overload

- Pellet mill central system

- Largely sized

- Rollers and die longevity

- Long-lasting

- Automation level

- Strong automation and electricity know-how

- Automatic greasing

- Yes, with used grease recovery

- Pellet contamination

- Limits with grease

- Abrasion resistance

- High

- Biological compatibility

- Animal feed

- Cleanability

- Easy and limited cleaning

- Corrosive resistance (e.g. acids)

- Carbon and stainless steel

- Density/particle size

- Various powders, grains

- Compression of powdery products

- Yes

- Animal nutrition

- Yes

- Machine footprint

- Height compact construction

- Transmission method

- Double set of belts

- Noise level

- Low noise level

- Vibration level

- Restricted vibration level

- Modulation of die speed

- 3.8 to 6.7 m/s

- Transmission type

- Double set of belts

- Rollers temperature control

- Available

- Ultra slow two-way die speed

- Available

- Forced feeding by screw

- Available

- Automatic distance adjustment between rollers and die

- Available

- Motorized pellet knives

- Available

- Heated door

- Available

- Regulation of meals and steam feeding

- Available

- Compact footprint

- Height compact construction