Black Soldier Fly Equipment

Find innovative production technology for making black soldier fly protein and connect directly with world-leading specialists

Black Soldier fly larvae (BSF or BSFL), also known by its scientific name, Hermentia Illucens, offer great nutritional values, making them an excellent alternative protein source for animal feed and pet food. Black soldier fly technologies have evolved sufficiently to turn the insect into a viable food ingredient. But there is no official authorization for human consumption yet and you are unlikely to find them at a restaurant anytime soon.

Top picks for insect processing

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

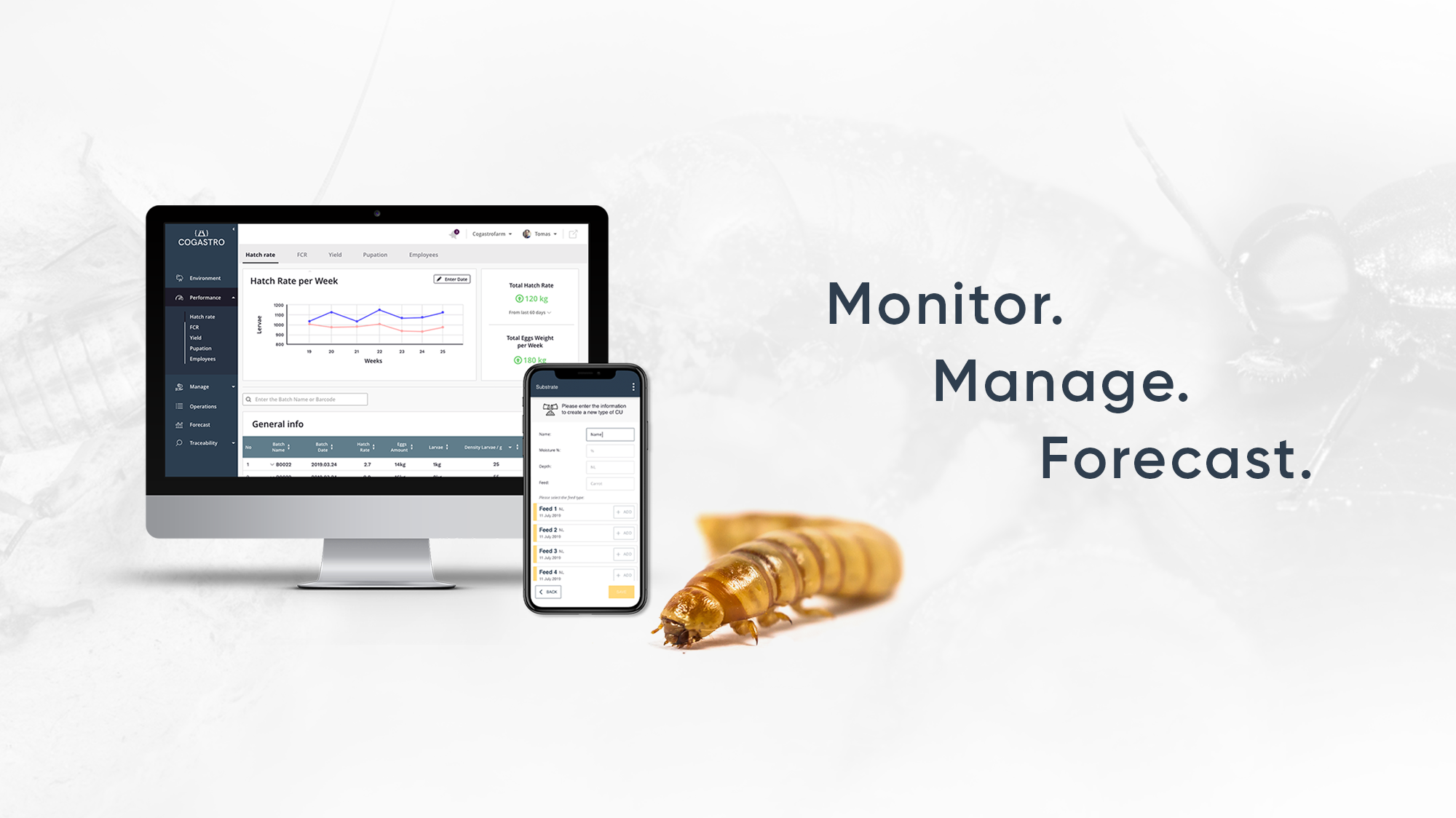

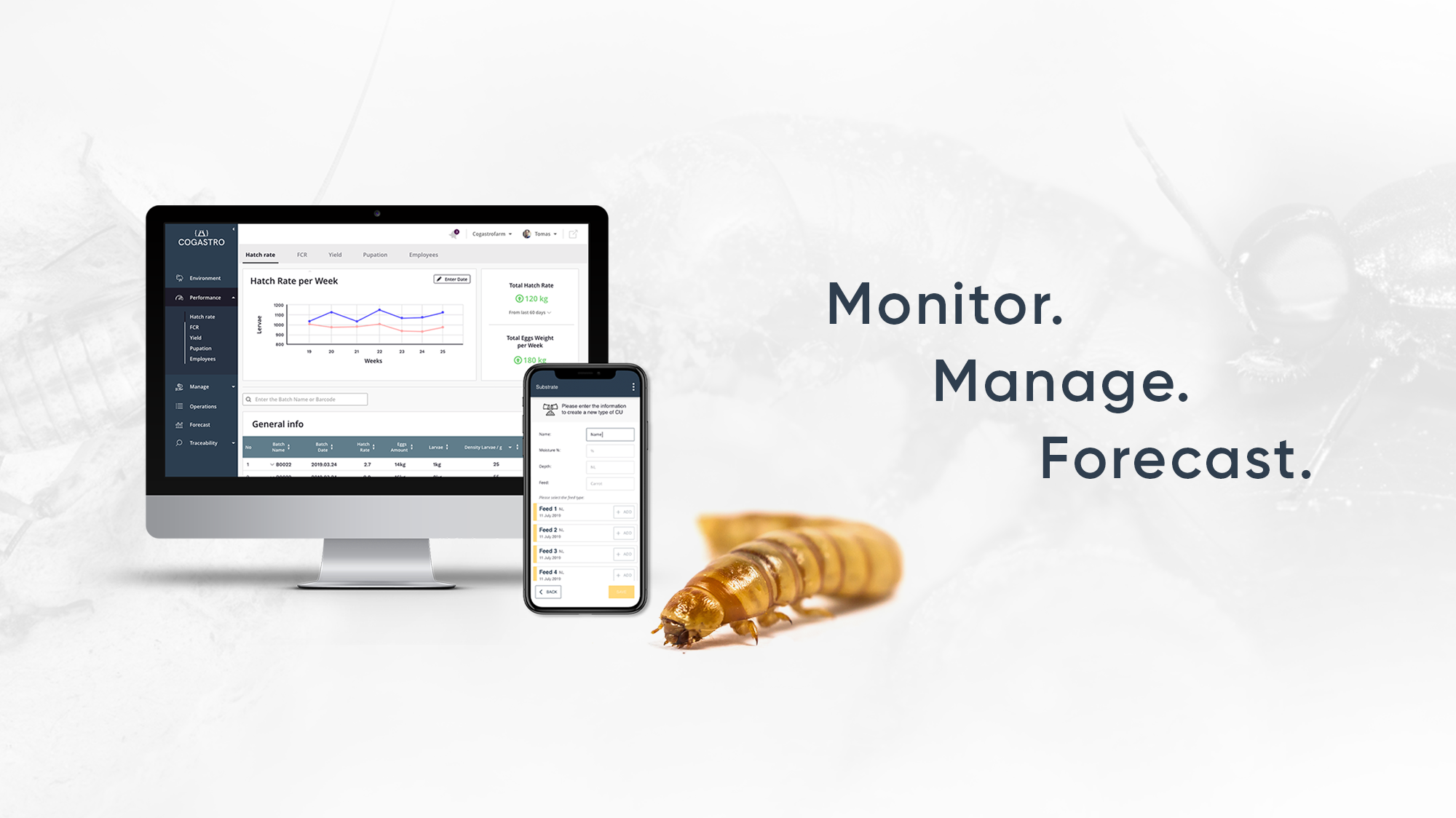

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Select your black soldier fly protein process

Tell us about your production challenge

BSFL is plentiful in nutrients

The larvae of the black soldier fly contain a variety of nutrients that can replace traditional substances used in animal feed or aquafeed. The micro- and macro-nutrients in the larvae make them an excellent component for the rearing of animals including fish, chickens, and pigs.

Rich in proteins, lipids, and minerals such as zinc and iron, BSF products are a viable resource for the farming industry. Fat contents make the resource less useful for the farming of ruminants, but the impact of BSFL on meat production can only increase.

The black soldier fly processing technology to produce protein

Tropical climates are ideal for BSFL farming and you can achieve these conditions with an HVAC system. Before starting the extraction process, harvested larvae need to be cleaned with specialized technology such as an immersion washer.

Heating or cooling equipment including boilers, fryers, freezers ensure that the larvae are inactivated. You can remove any residual water with belt dryers or rotation drums and crush the mass using mills or crushers. The BSF protein meal is now ready to be extracted. Press the material to separate the protein meal from insect oil.

A feasible alternative to animal feedstock

Nurturing black soldier flies takes up considerably less land than crops and grains that normally go for feeds. The fast growing rate of larvae also means that a site can be reutilized more quickly.

The insects are fed other organic matter, recycling a range of waste streams generated by agricultural, animal, or human activities and creating a closed loop food system. Moreover, larvae achieve a high conversion efficiency, producing proteins with minimal wastage.

A win for sustainable agriculture

Black soldier fly production offers a safe and low-price alternative to mainstream protein products. With further regularization of the cultivation method, its production can reach standardized treatment and processing across different regions.

Black soldier flies are an important agent of natural nutrient recycling, making BSFL protein a game-changer in sustainable agriculture. Furthermore, BSF can also be used to turn food waste and organic waste into biomass. Thus, not only making them useful for agriculture and feed but also for waste management and biomass production.

Processing steps involved in black soldier fly protein making

Which black soldier fly protein technology do you need?

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

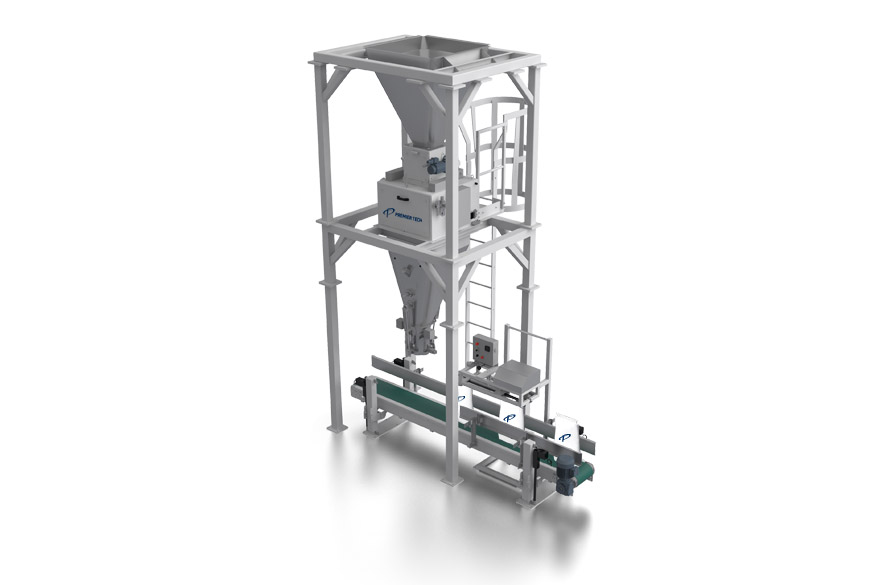

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...