Insect Protein Production

Find innovative insect protein equipment and connect directly with world-leading technology suppliers

With the increase in the world population and rising concerns for environmental sustainability, the market for suitable new protein sources is expanding rapidly. Traditional agricultural methods alone can’t deliver sufficient protein to meet the projected food demand over the next decades. Insects provide an alternative source of nutrients. But insect protein does not mean direct insect consumption. Extracting protein and amino acids from farmed insects is more sustainable and efficient. Specialized insect protein processing technology is driving the transformation toward new protein sources.

Innovative solutions for processing insect protein

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

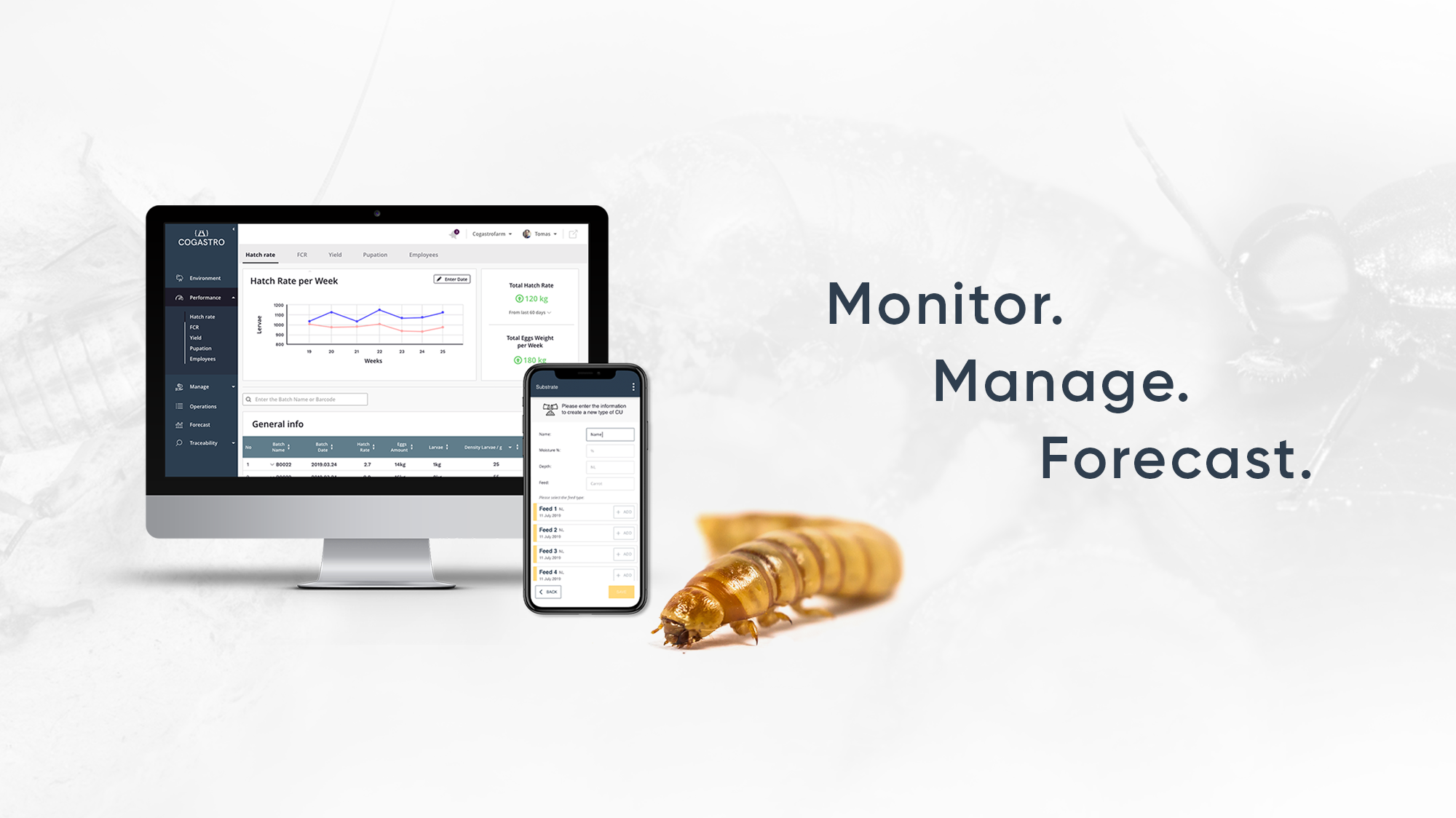

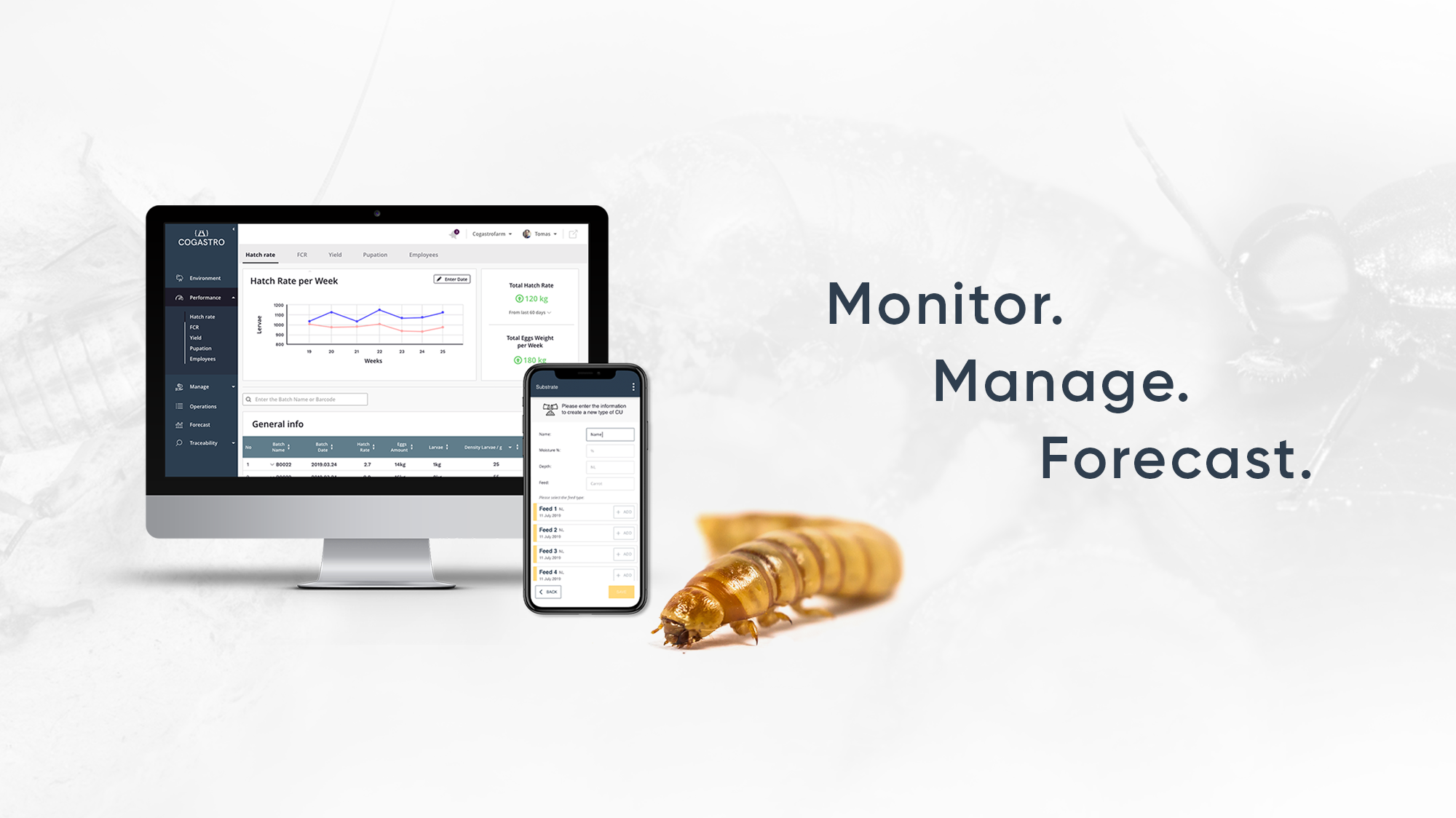

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

Stories about insect protein

Select your insect protein process

What are you making?

Tell us about your production challenge

2 kilograms of organic waste yields a kilogram of insect protein extract

The energy content of edible insects is similar to traditional fresh meat – around 500 calories for every 100g of dried product. Insects have an excellent protein density (between 45 and 65% protein by mass) and require far fewer resources to breed and rear than other farming practices.

While insect protein processing technology addresses the “protein gap,” insect farming also converts organic waste to a high-efficiency rate. With only 2kg of feed from food waste and a mere square meter of space, farmed insects can produce up to 1kg of protein.

Substitute fishmeal powder with insect protein extract

The aquaculture sector has already embraced the potential for insect protein. Protein derived from insects such as house fly larvae is a near-analog of fishmeal protein traditionally used as the base for commercial fish feed.

Processed insect protein is a more sustainable aquafeed ingredient and can replace traditional fishmeal powder from the feed mix.

Insect protein for use in agricultural animal feed

Insect protein from black soldier fly larvae (BSFL) is a suitable alternative base ingredient for pet food. Besides protein, BSFL contains fats and oils to make a richer foodstuff for domestic animals.

The high absorbency of insect protein makes it particularly useful as a base for pet food for animals with allergies and sensitive stomachs. Black soldier flies are reared on biomass from other agricultural processes and extract up to 70% of proteins. This makes them a highly sustainable option for animal feed.

Insect protein processing technology can be adapted for food-grade applications

Protein derived from farmed crickets has been granted novel food status in the European Union. Harvested insects are dried and ground into protein-rich powders.

So-called “cricket flour” can be used to make a whole range of foods, including cricket burgers, cookies, and performance products.

Freeze-dry mealworms to conserve their protein content

Previously produced commercially as fishing bait and pet reptile feed, mealworms are increasingly being farmed as an alternative source of protein. They require only 10% of the land needed for livestock and have a smaller greenhouse footprint.

Mealworms are rich in protein and retain around 40% of their content when freeze-dried. Mill the insects into a powder to broaden its application in the food and feed sector.

Heat sensitivity is a production challenge for insect processing

Insect protein processing technology encompasses farming, extraction, and finishing. Typically, the process includes two stages: separation & extraction and drying & milling.

But insect material is temperature sensitive and presents particular handling challenges. Moreover, since insects are often reared on wet feed, processing contends with poor flow characteristics and cohesive tendencies.

Apply indirect drying for gentler treatment

Drying is a delicate step in the insect processing line because it can alter the properties of the material. Under-dried insects develop bacteria, while over-drying causes scorching and reduces the protein’s nutritional value.

Two main types of dryers are used: Direct and Indirect drying. Direct drying is when the material is treated with hot air at a temperature of 200-300ºC as it goes through the heat exchange unit. This is quicker, but heat damage is much more likely if the process is not carefully controlled. Indirect drying offers a gentler approach. In this technique, the energy transfer is performed through a heating medium like steam-heated discs.

Insect protein powder for human consumption must be milled to a finer grade

The last step in insect protein processing is milling or grinding. The material can be milled into powder of different grades according to its final use. Powders intended as insect “flours” for baking and food recipes must be ground very finely. Ingredients for soluble products like protein drink powders require ultra-fine milling.

However, a coarser grade is more appropriate if the final use is for animal feed. Choosing a combined drying and milling solution can give you the edge in terms of efficiency and ROI.

Which insect protein technology do you need?

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...