Making Fishmeal Powder

Find innovative production technology for making fishmeal powder and connect directly with world-leading specialists

The fishmeal powder market forecast shows that its global market value will reach USD 10.3 billion by 2025. Expanding since 2019, at an annual growth rate of 6.5%. Fishmeal powder production has strong business potential with the increase of applications in animal feed, pet food, and fortified foods.

Select your fishmeal powder process

Tell us about your production challenge

Control the drying process to retain the nutritional value of fishmeal

Fishmeal powder production can be done with wild capture, by-catch, and by-products from the fish processing industry. This is a fairly standardized manufacturing process, in which drying is a critical step to retain the nutritional value of fishmeal.

Drying fishmeal is a sensitive and critical process. This is why you need to control temperature, moisture, and time. If the cake is not adequately heated and dried, it will be prone to bacteria and mold. On the contrary, if over-dried, it will lose its nutritional value.

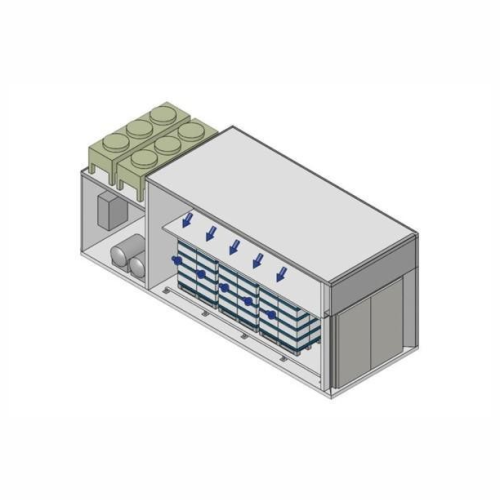

Apply indirect drying to avoid contact with fuel gases

Direct drying, is commonly known as flame-dried and is performed with a cylindrical drum. This is a quick and efficient process that uses direct fire or direct hot air. Although there is a risk of exposure to fuel gases for the fishmeal cake, this method remains widespread in fishmeal powder production.

Avoid contact with fuel gases by treating the cake with indirect drying. This process, also known as steam-drying, has a longer residence time during which the fishmeal cake is only in contact with a surface heated by steam. This keeps the cake and air, free of polluting fuel gases. In addition, you can recycle the steam vapor for other processes in your plant.

The feed sector expects improvements in fishmeal powder production

Fishmeal is one of the most digestible and nutritious ingredients used in animal feed. Its protein content ranges between 62% to 70%, while it is a rich source of Omega-3 fatty acids. But beyond its nutritional value, the feed sector expects sustainable improvements in fishmeal powder production.

They are looking for alternative ingredients such as black soldier fly protein that promise a smaller ecological footprint. Thus, fishmeal manufacturers need to address sustainability challenges. They can do it through responsible sourcing and process optimization.

With an improvement of product quality, while safeguarding the environment, the fishmeal market has many opportunities to expand and feed the growing population.

Processing steps involved in fishmeal powder making

Which fishmeal powder technology do you need?

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining...

Vertical flash dryer for industrial drying applications

Optimize your production line with an energy-efficient vertical f...

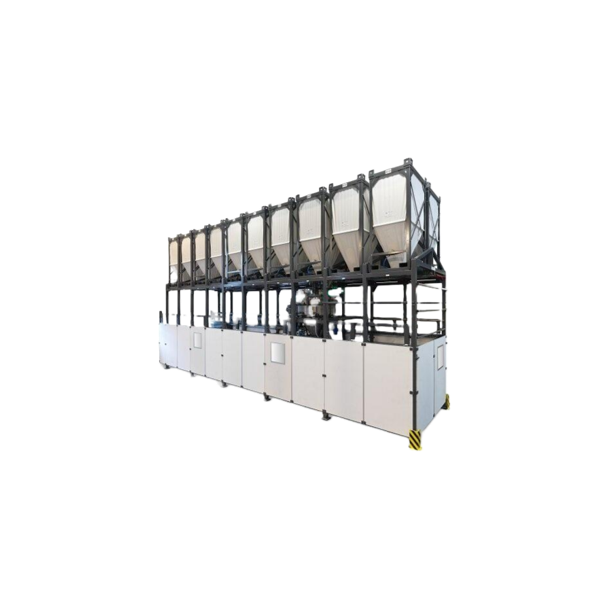

Industrial weighing and batching system for meat, poultry and seafood

Optimize your production line with a high-precisi...

Decanter centrifuge for protein extraction

Efficiently enhance your recovery of valuable proteins and fats with customizab...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

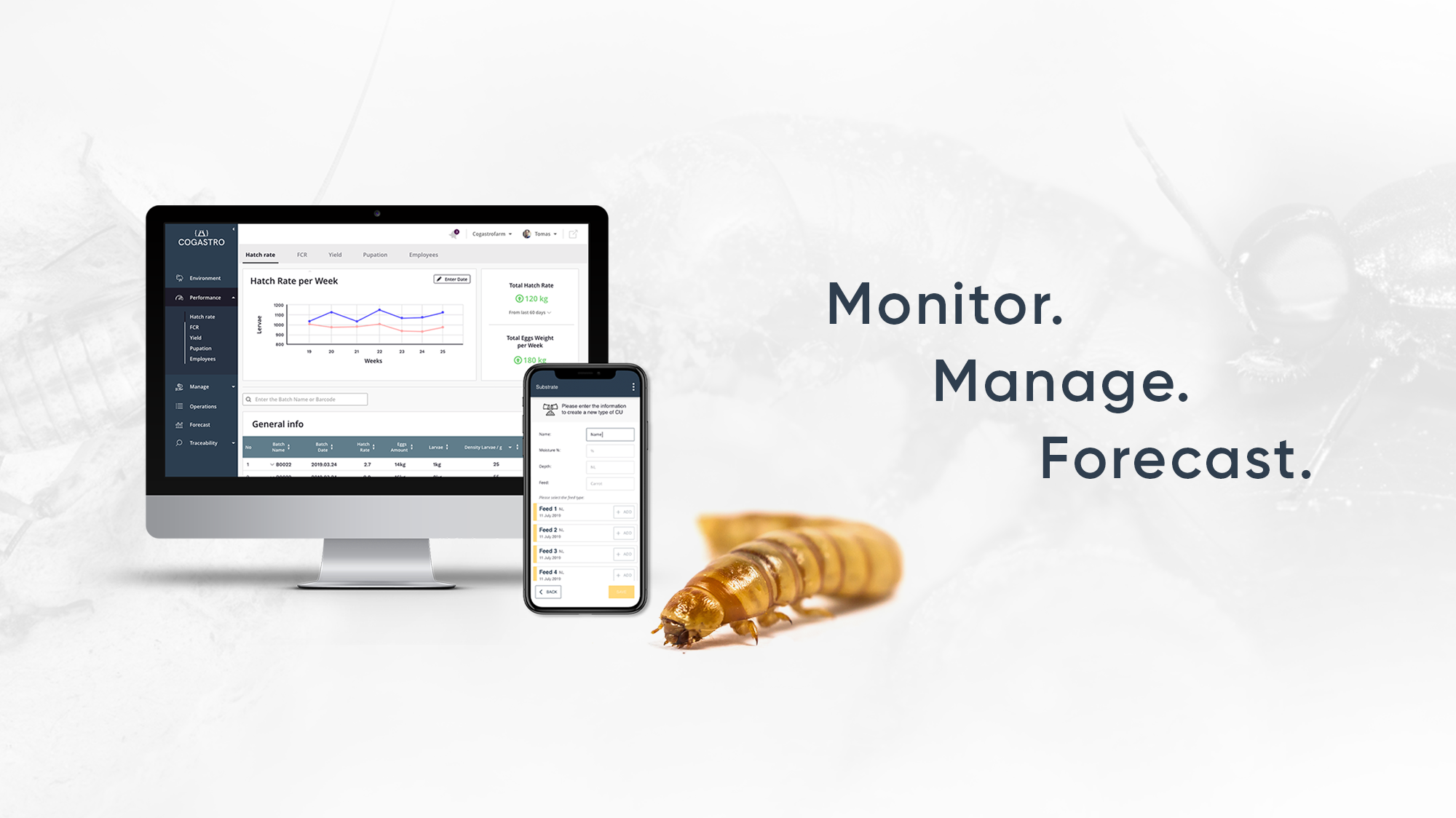

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

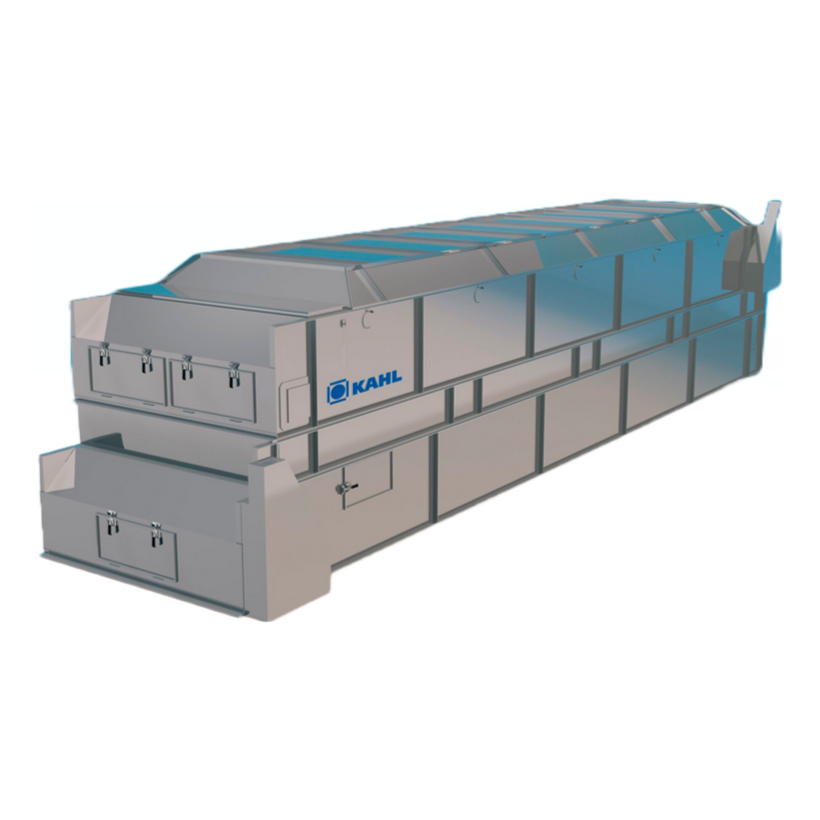

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Simple valve sack packer

Sometimes in the packing process, product leaks out of the top of a bag that has just been filled. A...

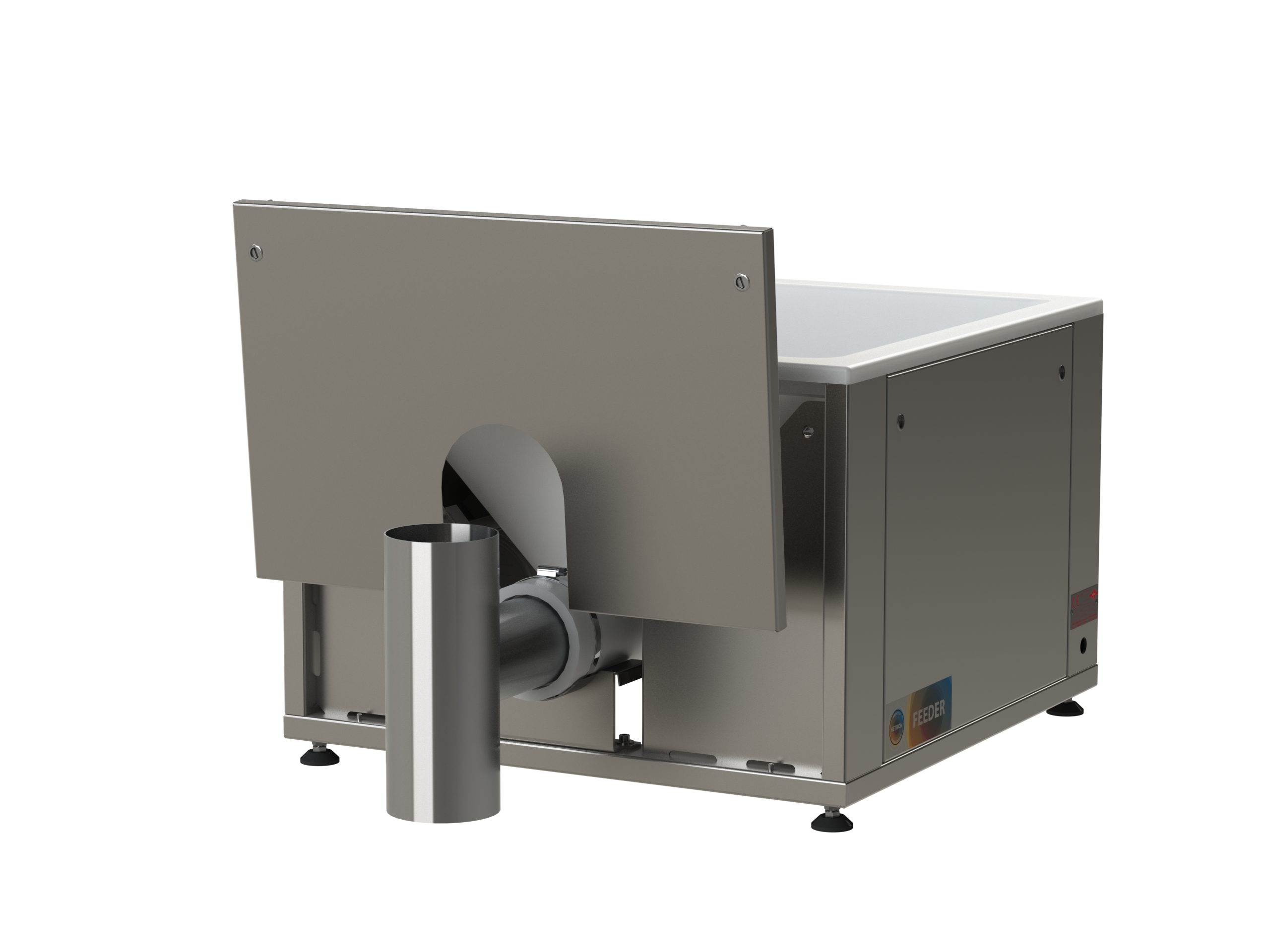

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

Industrial vacuum conveyor

Oftentime utilized as an alternative to mechanical conveyors when a requirement for dust free con...

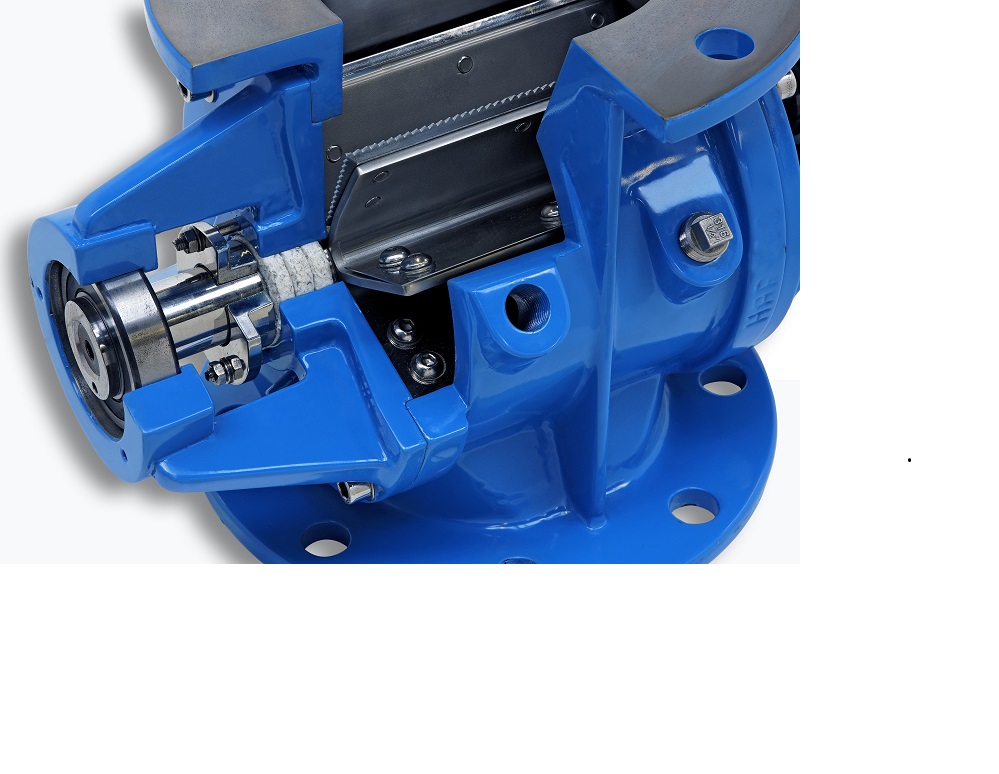

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Compact palletizer

Choosing an accurate palletizer can be quite an advantageous move. This one is designed for euro, industri...

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

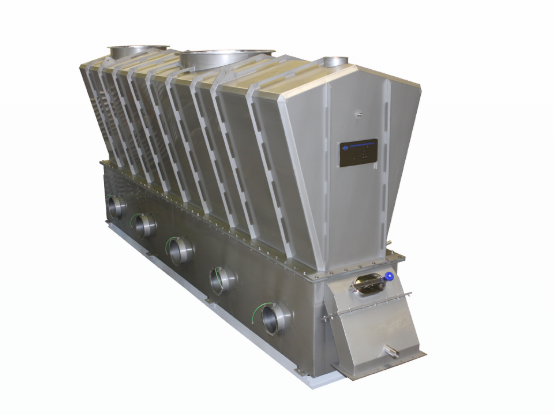

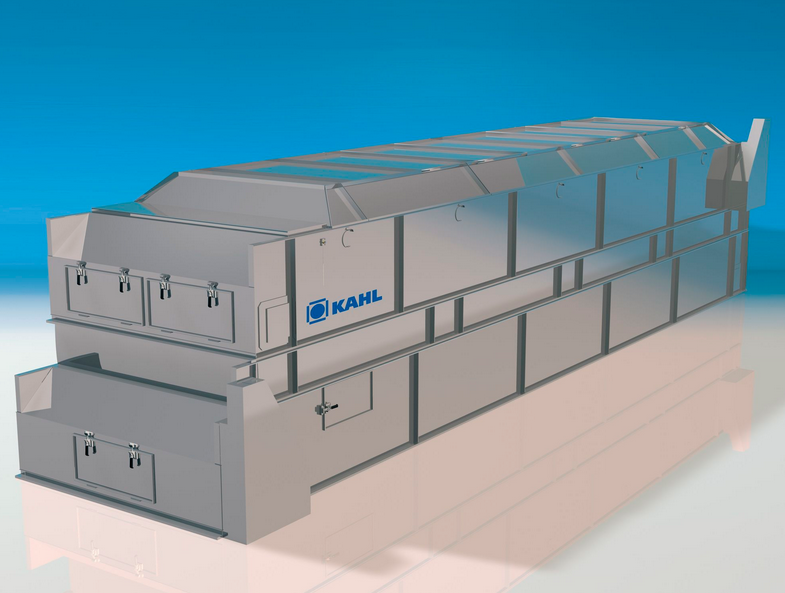

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...