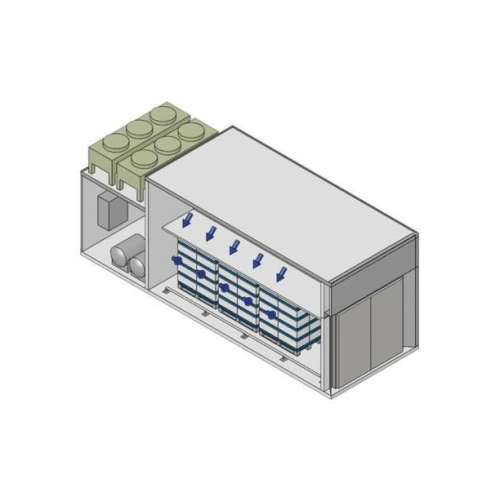

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining quality. Ideal for operations requiring scalable, modular solutions, these systems ensure effective cold storage and thawing, seamlessly integrating into high-capacity production lines.

Freezes and Stores High-Volume Food Products

Finncold tunnel freezer systems from Kometos offer robust freezing and storage solutions tailored for the food industry’s demanding environments. These systems excel with modular design and high-capacity processing, essential for meat, poultry, seafood, ready meals, and bakery production. Utilizing a hermetic refrigeration compressor and efficient air circulation, they ensure rapid freezing and consistent quality preservation. Ranging from compact 2,500 kg tunnels to expansive 40,000 kg storage units, they offer a range of capacities to suit various production needs. The systems integrate seamlessly with existing workflows, featuring thermostat-controlled processes and energy-efficient components using refrigerant R449. Constructed with food-grade materials and stainless steel frames, they meet stringent hygiene standards. Their modular nature allows for easy customization and expansion, accommodating growth and specific operational requirements. Smart plug-and-play installation, paired with comprehensive engineering support, ensures quick setup and minimal downtime. Perfect for businesses seeking precise temperature control and flexibility in food storage and freezing operations.

Benefits

- Optimizes production flow by accommodating large volumes with a flexible modular design.

- Enhances product quality with rapid freezing and stable temperature maintenance.

- Lowers operational costs through energy-efficient cooling and air circulation systems.

- Meets international food safety standards with hygienic design and materials.

- Scales easily with production growth due to its customizable configuration.

- Applications

- Ready meals, Confectionary products, Potatoes, Fruits, Fish and seafood, Vegetables, Meat and poultry, Bakery products

- End products

- Rye bread, Chocolate chip cookies, Diced carrots, Poultry fillets, Beef steaks, Frozen fish fillets, Shrimp cocktail, Croissants, Frozen berry mix, Ready-to-eat lasagna, Mashed potato blocks, Marzipan candies

- Steps before

- Packaging, Grading, Sorting, Cutting, Cooking

- Steps after

- Packing, Labelling, Quality Control, Distribution

- Input ingredients

- raw meat, poultry, cooked meat products, ready meals, fish, seafood, vegetables, potatoes, fruits, berries, bread, confectionary products, baked goods

- Output ingredients

- frozen meat, frozen poultry, frozen cooked meat products, frozen ready meals, frozen fish, frozen seafood, frozen vegetables, frozen potatoes, frozen fruits, frozen berries, frozen bread, frozen confectionary products, frozen baked goods

- Market info

- Kometos is known for manufacturing modular and mobile food processing facilities and equipment, offering innovative and tailored solutions for the food industry. Their expertise lies in efficiency, hygiene, and customization, enhancing clients' production capabilities.

- Size

- 5600 x 2900 x 3500 mm

- Capacity

- 6 Euro pallets or 2, 500 kg

- Temperature Range

- +5 °C to -20 °C

- Freezing Time

- 18 – 22 hours

- Weight

- 4, 500 kg

- Electrical Connection

- 3 x 400 V / 100A

- Cooling Capacity

- 23 kW (-35 °C / +32 °C)

- Cooling System

- Hermetic refrigeration compressor

- Air Circulation

- Propeller fans

- Control

- Thermostat controlled freezing process

- Size

- 9725 x 3200 x 3500 mm

- Capacity

- 12 Euro pallets or 5, 000 kg

- Weight

- 5, 500 kg

- Electrical Connection

- 3 x 400 V / 160A

- Cooling Capacity

- 2 x 23 kW (-35 °C / +32 °C)

- Size

- 13400 x 3500 x 3500 mm

- Capacity

- 20 Euro pallets or 10, 000 kg

- Weight

- 7, 000 kg

- Electrical Connection

- 3 x 400 V / 260A

- Cooling Capacity

- 4 x 23 kW (-35 °C / +32 °C)

- Size

- 13400 x 3200 x 3500 mm

- Capacity

- 30 Euro pallets or 15, 000 kg

- Weight

- 14, 000 kg

- Electrical Connection

- 3 x 400 V / 36A

- Cooling Capacity

- 13 kW (-20 °C / +32 °C)

- Size

- 13400 x 6400 x 3500 mm

- Capacity

- 2 x 36 Euro pallets or 2 x 20, 000 kg

- Cooling Capacity

- 13 kW (-25 °C / +32 °C)

- Cooling Capacity

- 18 kW (+4 °C / +37 °C)

- Automation level

- Thermostat-controlled

- Batch vs. continuous operation

- Batch

- Energy efficiency

- High - efficient cooling and air circulation

- Cleaning method

- Manual / CIP design

- Air incorporation control

- Propeller fans for air circulation

- Changeover time

- Quick - modular design adapts to changes

- Cooling option

- Hermetic refrigeration compressor

- Biological compatibility

- Adequate for food products

- Cleanability

- Moisture-resistant, easily cleanable surfaces

- Corrosive resistance (e.g. acids)

- Materials suitable for food-grade environments

- Machine footprint

- 5600 x 2900 x 3500 mm - 13400 x 6400 x 3500 mm

- Capacity

- 2, 500 kg - 40, 000 kg

- Frame

- Self-supported, specially designed welded metal frame

- Support legs

- 6 to 20 pieces, based on model

- Weight

- 4, 500 kg - 14, 000 kg

- Type

- Freezing tunnel / Frozen storage

- Cooling system

- Hermetic refrigeration compressor, condenser, and evaporator

- Cooling capacity

- 13 kW - 92 kW

- Refrigerant

- R449

- Freezing area

- +5 °C to -30 °C

- Air circulation

- Propeller fans

- Control

- Thermostat-controlled process with operating switches on the door frame

- Intermediate level

- Solid

- Temperature range

- +5 °C to -20 °C, -30 °C

- Defrost system

- Electric defrost

- Freezing capacity

- 2500 kg, 5000 kg, 10, 000 kg, 15, 000 kg, 40, 000 kg

- Modular design

- Yes, customizable sizes

- Freezing temperature range

- +5 °C to -30 °C

- Thermostat control

- Thermostat-controlled freezing process

- Operating switches

- On the door frame

- Cooling capacity

- 23 kW, 46 kW, 92 kW (-35 °C/+32 °C)

- Placement flexibility

- Indoor/outdoor installation

- Defrosting option

- Electric defrost for evaporator coil

- Air circulation

- Propeller fans

- Sizing

- Varied dimensions for different capacities

- Adaptability

- Flexible to increase as production grows

- Hygiene standards

- Moisture-resistant, easy to clean

- Frame support

- Self-supported, welded metal frame