Making Omega 3 Oil

Find innovative production technology for making omega 3 oil and connect directly with world-leading specialists

Fish oil was a folk remedy long before scientists identified the nutritional value of essential fatty acids. But Omega 3 processing has come a long way since the days of raw fish parts fermenting in a barrel. In fact, new supplement formulations of polyunsaturated fatty acids (PUFAs) may not use fish at all.

Select your omega 3 oil process

Tell us about your production challenge

Cool your fish oil extract immediately after wet pressing

The four stages of wet pressing – cooking, pressing, decantation, and centrifugation – extract and isolate the fish oils. But post-production cooling is critical to maintaining the purity of Omega 3 concentrates. Fish oils contain complex components. A warm environment activates hydrocarbons, fatty alcohols, waxes, and other elements, leading to spoilage.

Once in storage, you need to ensure that tanks are regularly drained from the bottom. Sludge and water deposits promote free fatty acids that compromise the final product.

Omega 3 processing by enzymatic silage

Fish silage is emerging as an alternative technique for the extraction of oils. Manufacturers treat the fish with additives like papain or flavorzyme to break down their properties. You can then recover essential fatty acids, or any other functional ingredients, from the mixture.

Long-chain polyunsaturated fatty acids (PUFAs) such as Omega 3 are notoriously susceptible to oxidation that develops off-flavors in supplements. Enzymatic silage prevents the oxidation of extracted oils and extends product shelf-life.

Exploit urea complexation to concentrate fatty acids in vegan Omega 3 supplements

Algal oil is a naturally rich source of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). After all, polyunsaturated fats originate in microalgae and move up the food chain as fish eat them. But concentrating Omega 3 in algal oil involves different processing techniques than fish.

Saturated fats are split from oil by capturing them in bonding molecules using urea fractionation. The remaining fatty acid mixture is purified through chromatography columns to separate PUFAs from monounsaturated fats.

Homogenize Omega 3 formulations with nanoemulsion techniques

A significant challenge of oil-in-water Omega 3 encapsulation is that formulations may become physically unstable over time. Developments in nanoemulsion techniques minimize this problem by phasing water and oil together in homogenized droplets of 100 mm or smaller.

Specialized technologies such as high shear mixers or colloid mills homogenize the molecules and emulsifiers. Besides higher stability, supplements produced with nanoemulsion also favor bioavailability.

Processing steps involved in omega 3 oil making

Which omega 3 oil technology do you need?

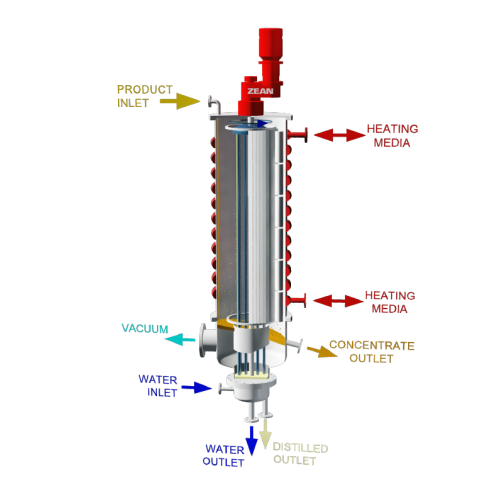

Short path evaporator for high vacuum distillation

Achieve high-efficiency separation and purification of sensitive compo...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

Vacuum coater for petfood and livestock feed

Enhance nutritional value and product quality with precision liquid incorpora...

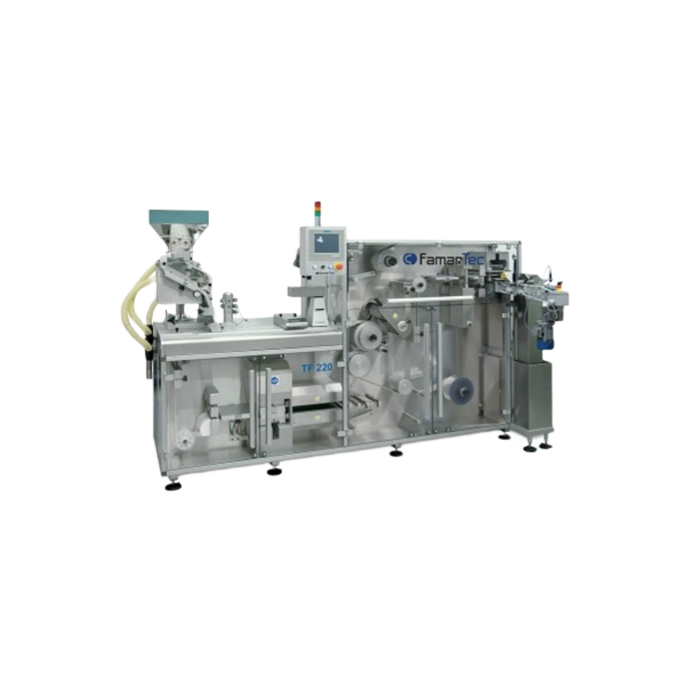

Form fill seal thermoforming machine for medical devices

Form Fill Seal thermoforming machines are those that produce pac...

Laboratory capsule filler for liquid solutions

A recent important change in the industry is the trend toward providing liq...

Laboratory scale soft gelatin capsule machine

Softgel (or soft gelatin) capsules are a very popular method for providing o...

Softgel tumble dryer

Softgel (or soft gelatin) capsules are a very popular means of delivering oral doses in the pharmaceutic...

Softgel capsules polisher

The final stage in high quality softgel (or soft gelatin) capsule production is the capsule polish...

Continuous in-line softgel drying system

High output softgel (or soft gelatin) capsule encapsulating machines can operate b...

Softgel drying tunnel

Softgel capsules require a controlled secondary drying to reduce water content in the capsule to levels...

Gelatin melters and tanks

When producing high quality softgels its important that the gelatin base is processed and stored c...

Automatic soft gelatin capsule machines

Soft gelatin (or softgel) capsules have become a popular mode of oral liquid dosing...

Automatic capsule filler for liquid solutions

Use of liquid filled hard capsules is increasingly popular with today’...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

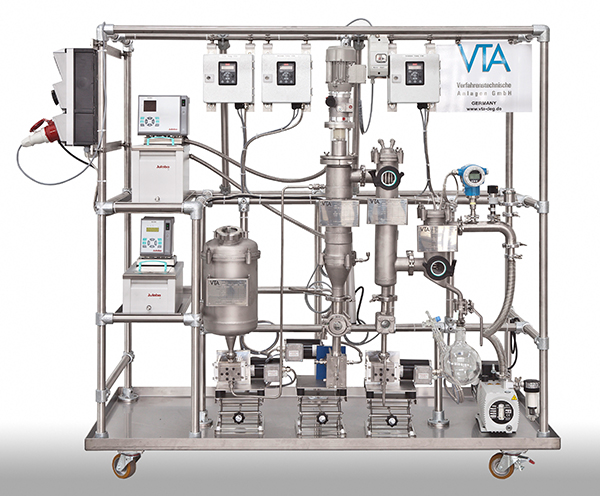

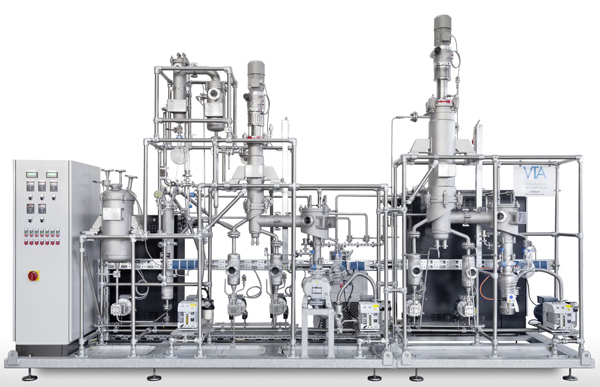

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Versatile X-ray inspection system

Versatile X-ray inspection system for product weight, quantity and shape to detect the pr...