Tablet inspection system

Connect directly with world-leading production technology suppliers of innovative tablet inspection system

To claim that a tablet meets quality requirements, you must perform several inspections to ensure its efficacy and patient safety. In addition to the tests described in official compendia such as weight variation test or dissolution test, visual inspection or metal detection are equally important. Metal detection identifies ferrous, non-ferrous, or stainless steel contaminants in tablets while visual inspection can detect defects such as color deviations, bubbles, or cracks.

Which tablet inspection system technology do you need?

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

Pharmaceutical metal detector for tablets and capsules

Ensure contaminant-free tablets and capsules with advanced detecti...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

High-containment tablet deduster

Ensure optimal purity and safety in pharmaceutical production with high-containment dedusti...

Table top tablet and capsule counter

Effortlessly ensure precise tablet and capsule counts with solutions that seamlessly i...

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

High-precision slat counter for tablet bottling

Optimize your tablet bottling with a low-energy, high-speed counter design...

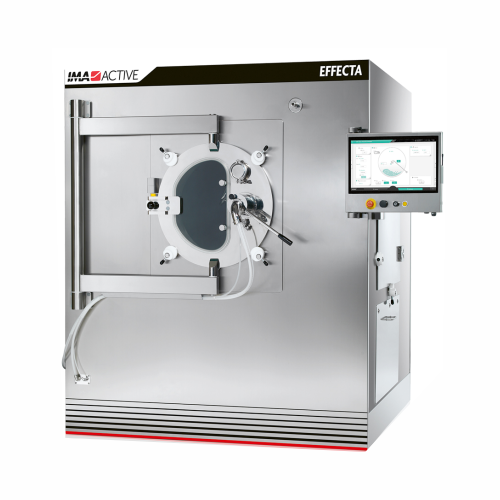

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

High performance tablet press for large batches

For manufacturers aiming to boost tablet production without sacrificing pr...

Tablet coating solution

Achieve precise tablet coating with uniformity and efficiency, tailored for diverse tablet types, ens...

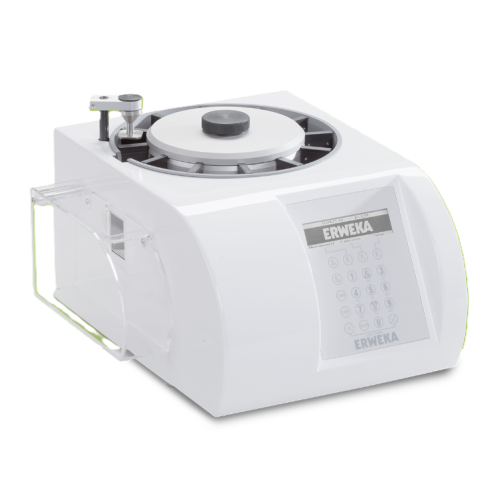

Tablet hardness tester

Ensure consistent tablet quality by precisely measuring hardness, thickness, diameter, and weight with...

Tablet hardness and combination tester

Ensure consistent tablet hardness and precision across multiple parameters with this...

Tablet hardness tester for pharmaceutical quality control

Ensure precise tablet hardness measurement to enhance pharmace...

pharmaceutical-tablet hardness testing system

Ensure consistent tablet quality and compliance with pharmacopeia standards ...

Shielded cell for radiopharmaceutical synthesis

Ensure operator safety and seamless radiopharmaceutical synthesis with adv...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Automatic visual inspection for sterile preparations

Ensure the integrity of sterile products with precise visual inspect...

Tablet press for multi-layer and dry-coated tablets

Optimize your tablet production with high-speed multi-layer pressing ...

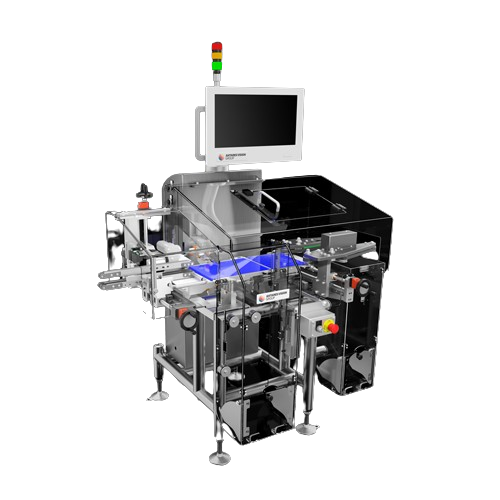

Pharmaceutical checkweigher for milligram-level accuracy

Ensure precision and compliance in your pharmaceutical packaging...

Tablet and capsule visual inspection system

Achieve unparalleled precision in tablet and capsule inspection with a high-sp...

Tablet coating for r&d and small-scale production

Achieve precise, efficient tablet coating with a compact, versatile mac...

Containment tablet coater for high-potency drugs

Ensure operator safety while achieving precise tablet coating on high-pot...

Tablet coating system for high-capacity operations

Streamline your tablet production with a coater that maximizes through...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Containment tablet coater for high-potency pharmaceuticals

Ensure operator safety and maintain stringent OEB 4 complianc...

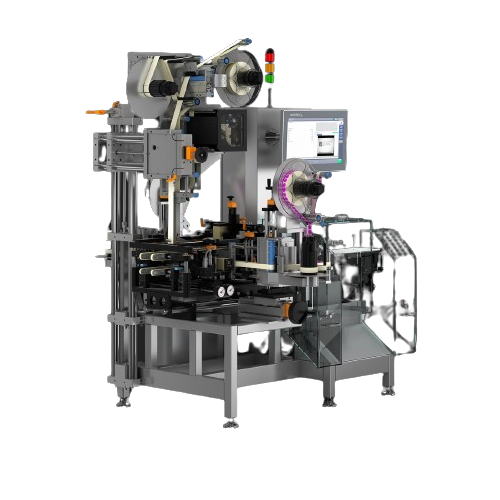

Compact serialisation system with tamper-evident and vignette labeler

Streamline your packaging operations with a high-...

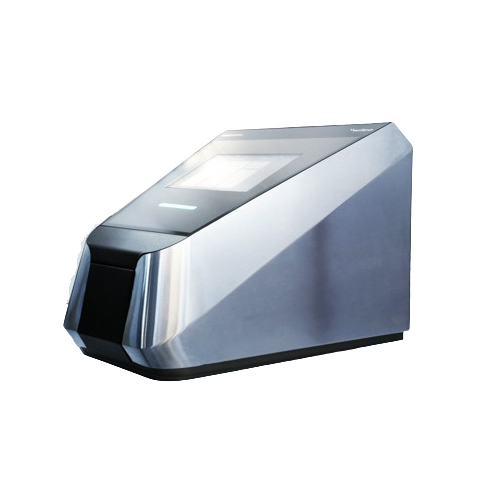

Headspace analyzer for small volume parenterals

Ensure precise gas concentration measurements in sterile pharmaceutical pa...

Combined visual and container closure integrity testing for vials

Ensure the integrity and quality of parenteral packag...

Laboratory dissolver for multiple applications

Efficiently streamline your laboratory processes with this versatile dissol...

Capsule checkweighing system for pharmaceutical production

Ensure every capsule meets your precision weight standards wi...

Tablet de-dusting system for pharmaceuticals

Ensure the highest quality of your tablets by effectively removing excess pow...

Tablet coating system

Achieve precise and uniform coating on pharmaceutical tablets with this scalable system, designed for o...

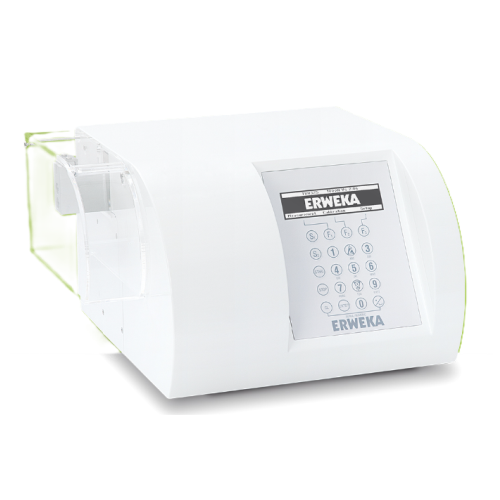

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Vision inspection system for tablets and capsules

Pharmaceuticals and healthcare product manufacturers dealing with oral ...

Inspection system for tablets chemical composition

The packaging of pharmaceuticals and oral solid products such as table...

Blister inspection system

The pharma and healthcare industries widely use blister thermoforming machines to package a variet...

Effective Visual Inspection System for Capsules

The attribute of capsule packing is a critical parameter that controls the...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Tablet counting machine

Production of pharmaceutical solid dosage forms usually require complete accuracy, flexibility, and c...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...