Headspace analyzer for small volume parenterals

Ensure precise gas concentration measurements in sterile pharmaceutical packaging with advanced headspace analysis, enhancing non-destructive testing accuracy and enabling seamless integration into your high-speed production line.

Non-Destructively Analyzes and Tests Packaging Integrity

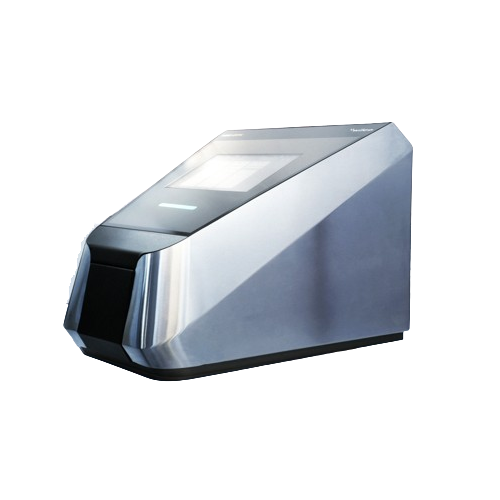

The NEO series by WILCO AG, encompassing the NEO HSX ONE, NEO HSX DUO, and NEO DPX, offers cutting-edge solutions for non-destructive headspace analysis and container closure integrity testing in the pharmaceutical and biotech industries. Utilizing advanced laser absorption spectroscopy, these systems precisely measure gas concentrations in sterile containers, including vials, syringes, and ampoules. Designed for applications from R&D to production, they ensure the integrity and compliance of small and large volume parenterals, pre-filled syringes, and more.

The NEO HSX series boasts industry-leading sensitivity with its 4th generation laser technology, providing up to 50% higher precision, ideal for thorough leak detection and ensuring product quality. The systems are automation-ready, featuring intuitive operation through the MAVIS interface and a customizable, operator-friendly design. The compact NEO DPX integrates pressure and vacuum decay methods, supporting versatile packaging types with deterministic testing compliant with USP1207 standards. Both series offer flexible configurations and seamless integration into existing production lines, supported by compliance with GMP, ISO Class 7 environments, and 21 CFR Part 11 regulations, ensuring robust quality assurance for pharmaceutical manufacturers.

Benefits

- Enhances product safety with precise leak detection and integrity testing.

- Increases operational efficiency by integrating seamlessly into automated and high-speed production lines.

- Ensures regulatory compliance with adherence to GMP, ISO, and FDA standards.

- Minimizes operator error with intuitive, user-friendly interfaces and guidance systems.

- Offers flexibility and adaptability for diverse pharmaceutical packaging and testing requirements.

- Applications

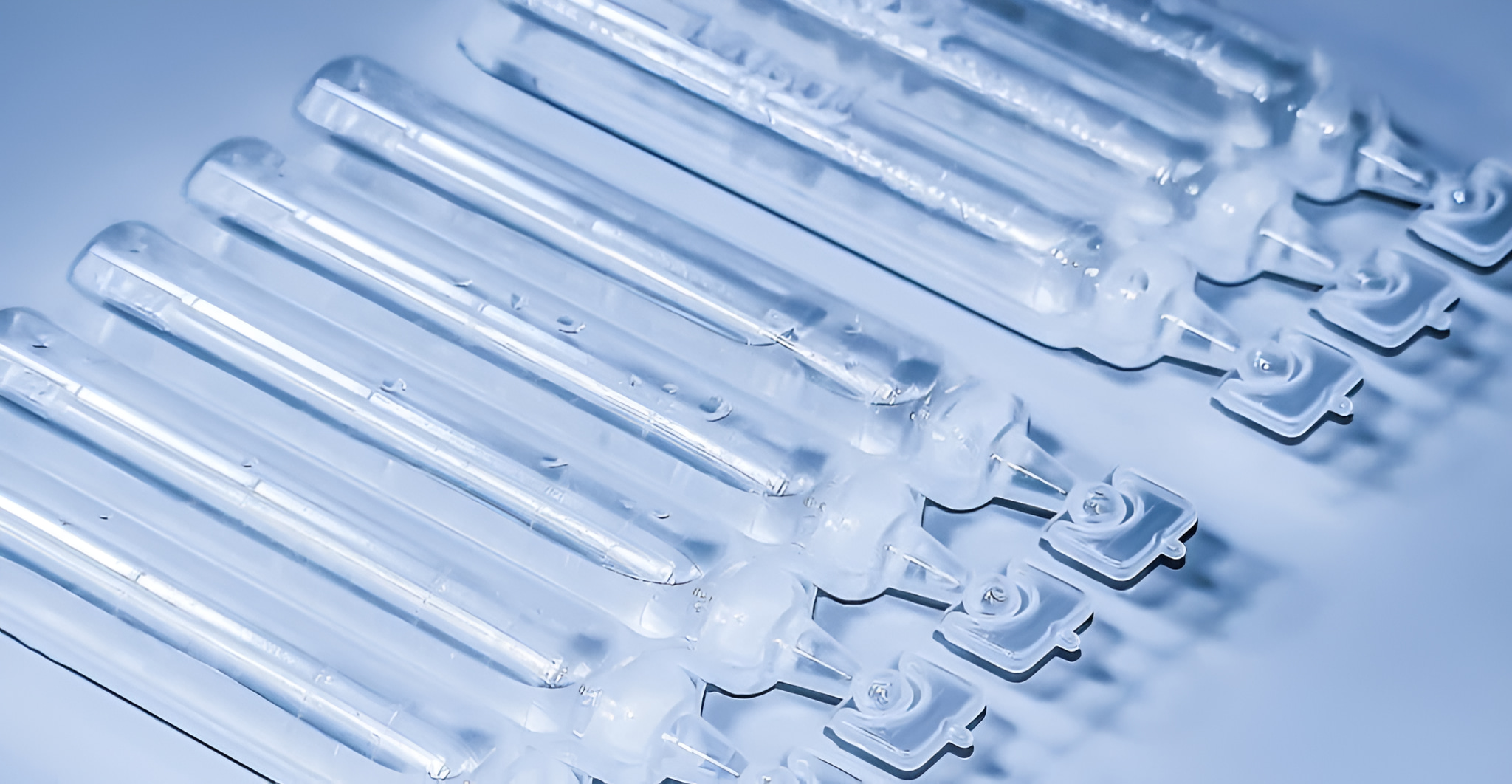

- Syringes, Containers, Medical packaging, Vials, Ampoules, Parenterals, Pharmaceuticals

- End products

- Bfs bottles, Iv bags, Bfs cards, Pre-filled syringes, Sterile vials, Small volume parenterals, Large volume parenterals

- Steps before

- R, D Method Development, Preparation of Samples, Filling Containers, Sample Collection

- Steps after

- Quality Control Analysis, Data Reporting, Production Scalability Assessment, Storage and Distribution, Product Release

- Input ingredients

- small volume parenterals, large volume parenterals, BFS cards, BFS bottles, IV bags, sterile pharmaceuticals, vials, ampoules, syringes, compressed air, carbon dioxide, trace gas, process gas

- Output ingredients

- oxygen concentration measurement, carbon dioxide concentration measurement, leak test results, media fill inspection results, residual oxygen measurements, headspace analysis data, container closure integrity test results, NIR lyo defect inspection results, visual inspection results, process analytical technology outputs

- Market info

- Measurement Accuracy

- ±0.1%–0.5%

- Laser Type

- O2 and CO2 laser

- Sample Holders

- Exchangeable

- Sample Volume Range

- Vials 1-100 ml, Ampoules 1-20 ml, Syringes 0.5-10 ml

- Compliance

- 21 CFR part 11

- Environment Compatibility

- ISO Class 7

- Automation

- PLC-controlled

- Display Size

- 12.1" color display

- Operation Modes

- GMP testing and development mode

- Detection Capability

- Leak rates down to 6.6 * 10^-6 mbar*l/s

- Connectivity

- OPC UA server

- Power Supply

- Integrated UPS

- Interface

- Customizable with widgets

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Integrated UPS

- Prevention of data loss

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Desktop type

- Headspace gas analyzer

- Sample holder position

- Exchangeable holders

- Control panel type

- 12.1" color display with LED status bar

- Protection

- Shield for environmental influences

- System size

- Compact benchtop

- Design

- Robust, compact, and mobile

- Control panel type

- MAVIS operation system

- Interface customization

- Customizable via widgets

- Sample holder options

- Exchangeable sample holders

- Laser head configuration

- Single or dual laser options

- Operating modes

- Development and GMP mode