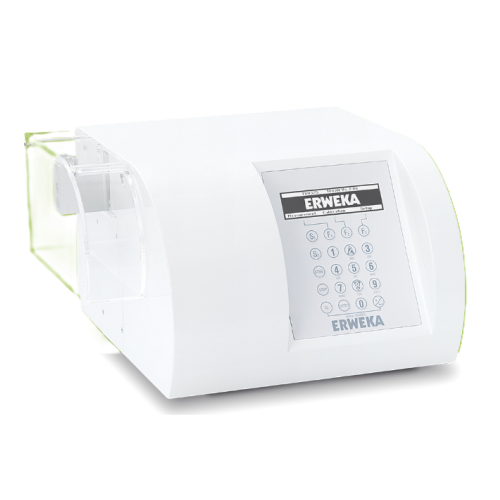

Tablet hardness tester

Ensure consistent tablet quality by precisely measuring hardness, thickness, diameter, and weight with a reliable manual bench-top solution.

Measures Tablet Hardness and Physical Dimensions

The TBH 325 series from ERWEKA includes robust tablet hardness testers designed for precise physical quality analysis in pharmaceutical production. This equipment stands out for its ability to test hardness, diameter, thickness, and weight of tablets, tailored to meet the rigorous demands of pharmaceutical manufacturers and biotech companies. Capable of measuring tablet hardness within a range of 10–500 Newton, the TBH 325 features adjustable modes—Constant Speed or Constant Force—to suit various testing needs. Users in quality control and R&D departments benefit from its integrated product memory for up to 50 products, ease of manual operation, and adaptability to various tablet shapes. This ensures compliance with USP, EP, and JP standards, essential for pharmaceutical QA processes.

The LAN/USB interfaces facilitate seamless integration with existing laboratory systems, and optional MC.NET software ensures 21 CFR Part 11 compliance for electronic records and signatures. The menu-driven calibration process, achievable via weight stones or ERWEKA’s AutoCal 2.0 system, allows custom adjustment points to ensure measurement accuracy and consistency across the tablet production line. Its compact design and efficient data management capabilities make the TBH 325 a versatile and indispensable tool for maintaining batch quality and supporting ongoing product development.

Benefits

- Ensures precise tablet quality control with customizable hardness, thickness, diameter, and weight measurements.

- Simplifies data management and enhances compliance with 21 CFR Part 11, facilitating efficient record keeping.

- Minimizes calibration time and error with menu-driven calibration using weight stones or automated systems.

- Supports a wide variety of tablet shapes and sizes, ensuring versatile application across multiple product lines.

- Enhances integration and control with LAN/USB connectivity, streamlining laboratory workflows and data transfer.

- Applications

- Supplements, Nutraceuticals, Pharmaceutical tablets

- End products

- Calcium tablets, Vitamin d supplements, Probiotic capsules, Herbal supplements, Multivitamin tablets, Omega-3 capsules, Aspirin tablets, Paracetamol tablets

- Steps before

- Mixing, Granulating, Coating

- Steps after

- Packing

- Input ingredients

- tablets, samples, batch/lot numbers

- Output ingredients

- hardness measurement, thickness measurement, diameter measurement, weight measurement, testing results, documentation

- Market info

- ERWEKA is renowned for manufacturing high-quality pharmaceutical testing equipment, including dissolution testers, tablet hardness testers, and other analytical instruments, known for their precision and reliability in laboratory testing environments.

- Measuring range

- 10–500 Newton

- Measuring modes

- Constant Speed / Constant Force

- Measuring sensitivity

- 3–40 N

- Test speed

- 0.05–3 mm/sec. or 10–200 N/sec.

- Thickness measurement

- Up to 12 mm

- Diameter measurement

- Up to 28 mm or 70 mm diameter

- Weight measurement

- Optional

- Calibration method

- Weight stones / ERWEKA AutoCal 2.0 System

- Interfaces

- LAN/USB

- Control software

- ERWEKA MC.NET software

- Working Mechanism

- Manual insertion, automatic hardness testing

- Measurement Modes

- Constant Speed / Constant Force

- Batch vs. Inline Operation

- Batch operation

- Automation Level

- Numeric membrane keypad

- Data Handling

- LAN/USB interfaces, printer connection

- Calibration Method

- Weight stones / ERWEKA AutoCal 2.0 System

- Product Memory Capacity

- Up to 50 products

- Display,Documentation Format

- Newton (N), Kilopond (KP), Strong Cobb (SC)

- Interface Type

- SD card / USB memory stick

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- USP compliance

- 100% USP/EP/JP

- EP compliance

- 100% USP/EP/JP

- JP compliance

- 100% USP/EP/JP

- 21 CFR 11 compliance

- Optional with MC.NET

- Machine footprint

- Compact

- Control panel type

- Numeric membrane keypad

- Discharge method

- Acrylic glass disposal container

- Design

- Robust

- Control panel type

- Numeric membrane keypad with alpha-numeric sub-function

- Integration possibilities

- LAN/USB interfaces for control and data transfer

- Calibration method

- Weight stones or electronic AutoCal 2.0 System