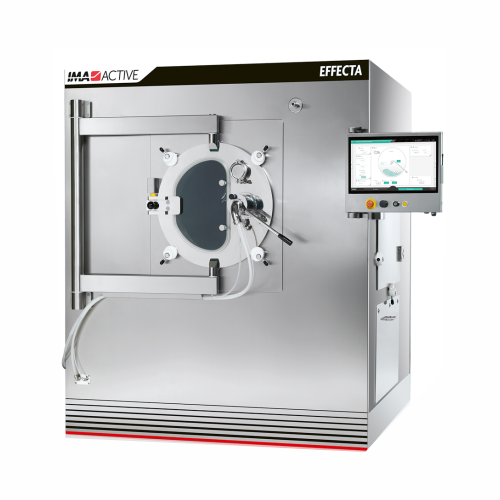

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution designed for seamless film and sugar coating processes, ensuring optimal mixing, energy savings, and consistent tablet quality.

Coats and Dries Pharmaceutical and Nutraceutical Tablets

The EFFECTA Coating Pan from IMA Group is engineered to streamline coating operations for pharmaceutical and nutraceutical tablet production. It features a perforated drum with specially designed baffles to enhance mixing and ensure uniform coating dispersion. With switchable spray guns, EFFECTA caters to both film and sugar coating processes, effectively addressing diverse product needs such as multivitamin and enteric-coated tablets. The machine offers a range of pan capacities from 18 to 750 liters, suitable for various batch sizes. Its strategically positioned outlet air duct optimizes drying while conserving energy. The integrated dosing unit minimizes spatial footprint, and easy inspection is facilitated by side doors. Through-the-wall installation capability enhances spatial integration within production lines. The MAX HMI provides intuitive control, improving operator efficiency. Compliance with industry standards ensures safe, reliable operation, while an advanced cleaning system reduces water use and downtime.

Benefits

- Optimizes coating uniformity, enhancing product quality for pharmaceutical and nutraceutical applications.

- Reduces energy consumption through efficient drying processes, lowering operational costs.

- Saves floor space with compact, integrated design, enhancing production area utilization.

- Minimizes cleaning time and water usage, increasing throughput and sustainability.

- Improves operator effectiveness with user-friendly MAX HMI, reducing training time.

- Applications

- Nutraceuticals, Coating materials, Pharmaceutical tablets, Pharmaceuticals

- End products

- Gelatin capsules, Enteric-coated tablets, Film-coated tablets, Herbal supplement tablets, Probiotic tablets, Multivitamin tablets, Sugar-coated tablets, Polymer-based coating materials, Cellulose-based coating materials

- Steps before

- Tablet Pressing, Core Formation, Initial Drying

- Steps after

- Additional Drying, Quality Inspection, Packaging

- Input ingredients

- tablets, sugar coating dispersion, film coating dispersion

- Output ingredients

- film-coated tablets, sugar-coated tablets

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Pan capacity

- 18-750 litres

- Pan diameter

- 985-1, 746 mm

- Pan mouth diameter

- 474-670 mm

- Pan motor power

- 1.5-7.5 kW

- Process air delivery

- 1, 100-8, 000 m³/h

- Automation

- MAX new corporate HMI

- Coating method

- Perforated coating pan

- Cleaning method

- Optimised cleaning sequence

- Drum type

- Functionally shaped perforated drum

- Spray guns

- Switchable for film or sugar coating

- Outlet air duct

- Positioned/dimensioned for optimal drying and energy saving

- Working mechanism

- Perforated coating pan

- Integrated steps

- Switchable spray guns for film or sugar coating

- Energy efficiency

- Optimal drying of cores, energy saving

- Automation level

- MAX new corporate HMI

- Cleaning method

- Optimised cleaning sequence

- Batch vs continuous operation

- Batch

- Changeover time

- Easy inspection through side doors

- CIP/SIP

- Minimised water consumption and washing time

- Cleanability

- Optimized cleaning sequence

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Coating type

- Film / Sugar

- Switchable spray guns

- Film or Sugar coating

- Pan capacity

- 18-750 liters

- Pan diameter

- 985-1, 746 mm

- Pan mouth diameter

- 474-670 mm

- Pan motor power

- 1.5-7.5 kW

- Process air delivery

- 1, 100-8, 000 m³/h

- Machine footprint

- Through-the-wall installation

- Control panel type

- MAX new corporate HMI

- Integration possibilities

- Through-the-wall installation

- Space-saving design

- Dosing unit housed in machine frame

- Spray gun configuration

- Switchable for film or sugar coating