High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety standards with this high-performance dedusting solution, designed for seamless integration into your production line while offering precise cleaning, efficient handling, and robust explosion protection.

Dedusts and Conveys Pharmaceutical Tablets and Capsules

The KD7070 from Krämer AG is a high-containment deduster tailored for pharmaceutical and nutraceutical manufacturers requiring stringent dust control during tablet and capsule production. This equipment features an upward conveying spiral system, allowing continuous dedusting and conveying with adjustable heights from 400 to 1600 mm. Suitable for a variety of end-products, including paracetamol and vitamin C tablets, the KD7070 ensures a dust-free, efficient process. It offers high throughput capabilities, handling up to 6.3 million tablets per hour, depending on size, while operating quietly at less than 68 dB. The unit’s Wash-in-Place cleaning system simplifies maintenance, ensuring compliance with OEB5 containment standards for high-potency products. Integration into existing production lines is seamless, thanks to the versatile tri-clamp connections and flexible control options. With certifications including ATEX Zone II compliance and GMP standards, the KD7070 ensures safe and reliable operation even in demanding environments.

Benefits

- Ensures high-containment handling of potent substances, safeguarding operator health.

- Enhances production efficiency with rapid dedusting and seamless conveying of up to 6.3 million units per hour.

- Reduces cleaning time and cross-contamination risk with efficient Wash-in-Place system.

- Offers flexible integration into existing production setups with adjustable inlet and outlet configurations.

- Complies with ATEX and GMP standards, maintaining operational safety and regulatory adherence.

- Applications

- Pharmaceutical capsules, Biopharmaceuticals, Nutraceuticals, Pharmaceutical tablets

- End products

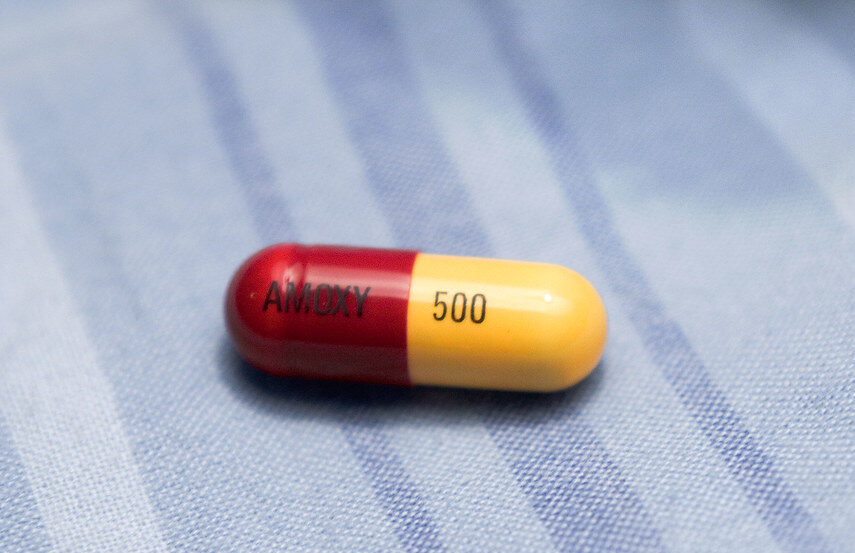

- Ibuprofen tablets, Calcium carbonate tablets, Antihistamine tablets, Coenzyme q10 capsules, Vitamin c tablets, Multivitamin capsules, Amoxicillin capsules, Effervescent aspirin tablets, Fish oil capsules, Paracetamol tablets

- Steps before

- Tablet Pressing, Capsule Filling

- Steps after

- Packing, Coating

- Input ingredients

- tablets, capsules, effervescent tablets, mini/micro-tablets, oblong tablets

- Output ingredients

- cleaned tablets, cleaned capsules, dust-free tablets, dust-free capsules

- Market info

- Kraemer is known for designing and manufacturing customized engineered-to-order equipment for industrial applications, leveraging advanced engineering expertise to deliver high-quality, reliable solutions tailored to meet specific client needs in various sectors.

- Upward conveying range

- 400 to 1600 mm

- Noise emission

- < 68 dB

- Conveying Capacity

- up to 6.3 million tph

- Conveying heights

- 400-1600 mm

- Tablet Diameter Handling

- 3-35 mm

- Capsule Sizes

- Nr. 4-00

- Power Supply

- 110-240 V, 50/60 Hz

- Peak current

- 3 A

- Compressed air

- Ø6/4mm, 50-100 l/min (p=3-6 bar)

- Air extraction

- 2" tri-clamp, 100-250m³/h (p=10-20 mbar)

- Water consumption

- 16-46 l/min

- Inlet height

- 471 mm

- Outlet height

- 905-2114 mm

- Total height

- 1514-2723 mm

- Conveying speed tablets Ø5 mm

- 6, 300, 000 tabs/h

- Conveying speed mini/micro-tablets <Ø2.5 mm

- 10, 300, 000 tabs/h

- Conveying speed tablet Ø13 mm

- 574, 000 tabs/h

- Conveying speed tablet Ø20 mm

- 240, 000 tabs/h

- Conveying speed tablet Ø25 mm

- 95, 000 tabs/h

- Conveying speed tablet Oblong 16.3 x 7.6 x 5.7 mm

- 770, 000 tabs/h

- Explosion protection

- ATEX II 2D/- Db 140 °C

- OEL Level

- OEB 5

- GMP compliance

- cGMP

- CE compliance

- Yes

- Working mechanism

- Upward conveying spiral

- Vibration control

- Acceleration sensor for constant vibration

- Noise level

- < 68 dB

- Automation level

- Manual / Auto

- Cleaning method

- WIP (Wash-in-Place) manual or automatic

- Conveying capacity

- Up to 6.3 million tph

- Containment level

- OEB5 (< 1 μg/m³)

- Cleaning integration

- Efficient helix with integrated washing nozzles

- Process insight

- Dust-proof and removable PETG window

- Controller placement

- Right or left side

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Wash-in-Place, manual or automatic

- Corrosive resistance (e.g. acids)

- Stainless Steel AISI 316L

- Density/particle size

- Tablets Ø3–35 mm, capsules Nr. 4-00

- ATEX certification

- II 2D/- Db 140 °C

- OEL Level

- OEB 5

- Machine footprint

- 615-520 mm

- Total height

- 1514-2723 mm

- Elevation height

- 400-800-1200-1600 mm

- Inlet height

- 471 mm

- Outlet height

- 905-2114 mm

- Compact design

- Yes

- Control panel type

- Backlit LCD Screen with touchpad

- Integration possibilities

- Connection and operation through press controls

- Conveying height options

- 400, 800, 1200, 1600 mm

- Cleaning mode

- Manual / Auto Wash-in-Place

- Drain valve system

- 4 way manual

- HEPA filter type

- H14 manually actuated

- Window type

- Dust-proof removable PETG

- Air extraction adapter

- Optional

- Helix coating

- Optional

- Inlet and outlet adapters

- Optional

- Sample collection

- Optional