Pharmaceutical checkweigher for milligram-level accuracy

Ensure precision and compliance in your pharmaceutical packaging line with a checkweigher that offers milligram-level accuracy, safeguarding product weight integrity and patient safety.

Weighs and Inspects Pharmaceutical Products

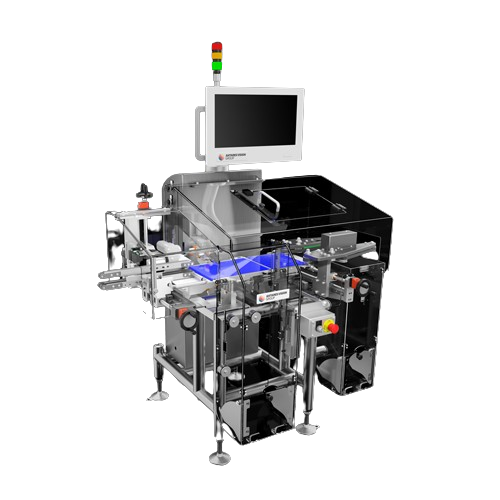

The HR600 PHC Checkweigher from Antares Vision Group is engineered for precise pharmaceutical applications, ensuring accurate weight control for lightweight packaged products such as tablets, capsules, and blister packs. This equipment stands out due to its high-speed, milligram-level weight assessment, achieved through a high-resolution load cell and optimized for seamless integration into existing production lines. Capable of handling up to 600 grams, the HR600 PHC operates at speeds up to 350 products per minute, making it ideal for continuous, high-speed operations. Automated functions such as self-learning calibration and data collection, accessible via its 15-inch touch screen, simplify user interaction and enhance efficiency. It supports robust error detection with fail-safe rejection systems, ensuring compliance with CE, BRC, IFS, and HACCP standards. Constructed with stainless steel and anodized aluminum, this checkweigher is designed for durability and ease of maintenance, with network connectivity options for remote assistance, emphasizing readiness for Industry 4.0 integration.

Benefits

- Ensures patient safety by maintaining precise dosing accuracy in pharmaceutical production.

- Increases operational efficiency with high-speed processing of up to 350 products per minute.

- Minimizes production line disruptions through autonomous error detection and fail-safe rejection systems.

- Enhances data-driven decision-making with integrated data collection and remote network connectivity.

- Complies with industry standards, supporting seamless integration into GMP-compliant production environments.

- Applications

- Packaged products, Lightweight pharmaceuticals, Pharmaceuticals

- End products

- Sachets, Single-dose vials, Blister packs, Ampoules, Tablets, Dispensers, Medical inserts, Capsules

- Steps before

- Filling, Cartoning

- Steps after

- Labeling, Packaging, Inspection

- Input ingredients

- lightweight pharmaceuticals, packaged products, inserts, dispensers

- Output ingredients

- accurately weighed pharmaceuticals, safely packaged products

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Accuracy

- 0.2 g ± (depending on working speed and characteristics of the product)

- Display Division

- 0.1 g

- Weighing Range

- Up to 600 g

- Working Speed

- Up to 350 ppm

- Conveyors

- Infeed

- Rejection Systems

- Pneumatic cylinder / Top-down ejector, with fail-safe system (optional)

- Working Height

- 750-950 mm

- HMI

- 15″ Touch screen

- Data Processing Electronics

- RISC Embedded FPGA

- Self-learning System and Calibration

- Included

- Data Collection Software

- Included through Ethernet and USB

- Network Connectivity

- Gigabit Ethernet Kit for Remote Assistance

- Power Supply

- 1.0 kW

- Rated Voltage

- 100/240V AC 50/60Hz single phase

- Protection Degree

- IP65

- Frame Structure

- Stainless steel and anodized aluminium

- Machine Net Weight

- 180 kg

- Automation level

- Autonomous error detection

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Manual

- Integration capability

- Seamless production line integration

- Product handling

- Tangential belts with top-down rejection

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Stable and compact framework

- Control panel type

- 15″ Touch screen

- Frame structure

- Stainless steel and anodized aluminium

- Working height

- 750-950 mm

- Machine net weight

- 180 kg

- HMI Type

- 15″ Touch screen

- Integration possibilities

- Ethernet and USB connectivity

- Network Connectivity

- Gigabit Ethernet Kit for Remote Assistance

- Rejection Systems

- Pneumatic cylinder / Top-down ejector, with fail-safe system (optional)

- Modular Framework

- Accessible, stable, and compact