Short path evaporator for high vacuum distillation

Achieve high-efficiency separation and purification of sensitive compounds using low thermal exposure with this short path evaporator, ideal for processes that demand precise vacuum distillation to preserve product integrity.

Separates and Purifies Heat-Sensitive Liquid Products

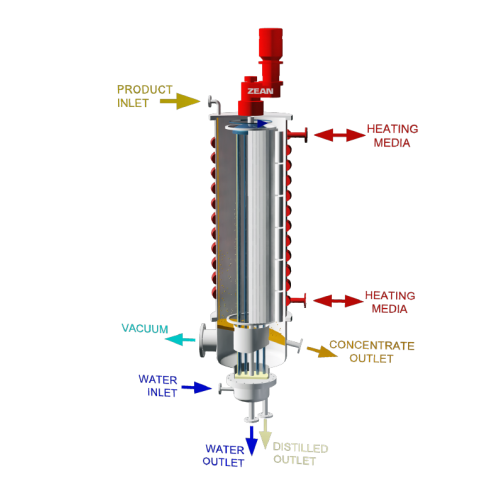

The Short Path Evaporator from De Dietrich Process Systems offers unmatched performance for the distillation and purification of heat-sensitive liquid compounds across various industries such as pharmaceuticals, nutraceuticals, and edible oils. This specialized equipment employs an internal condenser and rotor system with rollers and wipers, achieving high vacuum conditions up to 0.001 mbar and minimizing pressure loss. It’s particularly effective for separating squalene, sterols, and omega-3 fatty acids.

Operating with very low process temperatures, the evaporator maintains product integrity while reducing energy consumption. By handling both continuous and pilot operations, it ensures efficient processing, suitable for applications like refining mineral oil or improving the color and odor of intermediate chemicals. Constructed with carefully selected elastomers for specific temperature ranges, it offers optimal corrosion resistance, and its design supports easy integration into existing production lines. The evaporator complies with industry standards and includes options for customization to meet specific production demands.

Benefits

- Enhances product purity and quality with precise high vacuum distillation.

- Protects heat-sensitive materials with low temperature processing.

- Minimizes operational costs by reducing energy consumption significantly.

- Integrates seamlessly into existing production lines for efficient workflow.

- Customizable design offers compatibility with various product specifications.

- Applications

- Mineral oils, Fine chemicals, Omega-3 fatty acids, Intermediate chemicals, Edible oils, Nutraceuticals, Waxes, Sterols, Vitamin e, Squalene, Pharmaceuticals

- End products

- Candle wax, Enriched omega-3 concentrates, Vitamin e oil, Purified wax emulsions, Fish oil capsules, Polished intermediate chemicals, Pharmaceutical-grade sterols, Refined mineral oil, Tocopherol supplements, Food-grade squalene

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Distillation, Odour Improvement, Colour Enhancement, Purification, Concentration, Separation

- Input ingredients

- Squalene, Sterols, Vitamin E, Omega 3 fatty acids, intermediate chemical products, mineral oil, waxes

- Output ingredients

- distilled product, concentrated product, purified mineral oil, purified waxes

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Vacuum capability

- 0.001 mbar

- Separation efficiency

- High

- Operating temperature

- Suitable for low temperature

- Residence time

- Low

- Condenser type

- Internal

- Working mechanism

- Rotating distributor with internal rotor

- Internal steps

- High separation efficiency using rollers and wipers

- Pressure loss control

- Internal condenser

- Vacuum capability

- Up to 0.001 mbar

- Process temperature suitability

- Suitable for heat-sensitive products

- Residence time

- Low

- Product discharge

- Bottom section for concentrated product

- Distillation efficiency

- Improved by internal rotor design

- Application flexibility

- Handles squalene, sterols, Vitamin E, Omega 3 fatty acids

- Elastomer suitability

- High temperature resistance

- Corrosive resistance

- Mineral oils, acids

- Cleanability

- CIP / Manual

- Temperature resistance

- Processes with low temperatures

- Product type

- Squalene, Sterols, Vitamin E, Omega 3, Waxes

- Internal Rotor Type

- Rollers / Wipers

- Internal Condenser

- Yes

- Machine Footprint

- Compact

- Feed/Discharge Method

- Bottom Discharge

- Vacuum Pressure Capability

- Up to 0.001 mbar

- Operation Temperature

- Suitable for Heat Sensitive Products

- Internal Rotor Type

- Rollers/Wipers

- Elastomer Selection

- Specific Product, Temperature Matching

- Vacuum Level

- Up to 0.001 mbar

- Internal Condenser

- Integrated to Reduce Pressure Losses