Cricket Protein Equipment

Find innovative production technology for making cricket protein and connect directly with world-leading specialists

Crickets are better known for their nighttime serenades than for their nutritional notes, but their serious protein content as well as vitamin B12 content and iron, moves them into the category of superfoods. With a light brown color and a nutty taste, cricket protein powder is a versatile dietary ingredient that makes it difficult to go off-tune with your recipes.

Tell us about your production challenge

Cricket protein is way more digestible than whey

One of the advantages of edible insects in general is that they are easily digested by the human body. Crickets, particularly, boast a high level of bio-availability, efficiently transferring the amino acids from protein to rebuild muscles. To put it into context, crickets have almost double the amount of iron compared to spinach.

Whey is a popular source of protein because of its high digestibility, but cricket powder boasts a more effective rate of amino acid absorption by up to 50%.

Cricket farming and processing is viable

Since 2017, crickets have become the largest category in the global edible insects market. Besides their high nutritional value and adaptability as a food ingredient, crickets are easy to farm and process.

When ready for harvesting, they are freeze-dried, roasted, and ground into a fine powder that can be added directly to recipes from stir fry and dough to stews and smoothies.

Making cricket flour is resource-efficient

The cultivation of crickets drastically reduces the space needed to obtain protein from either animal-derived or plant-based products. Moreover, up to 80% of whole crickets can be consumed, and it is twice as efficient as poultry in converting feed to protein.

Crickets are grown on various safe foods such as grains or other residues from the agricultural sector. Besides consuming a lot fewer water resources than traditional protein sources, cricket farming makes a sustainable agri-waste management option.

Furthermore, using crickets as a snack and protein source has a positive impact on the environment in that they drastically decrease the amount of greenhouse gases compared to traditional meat protein sources.

Processing steps involved in cricket protein making

Which cricket protein technology do you need?

Industrial heat pump dryer

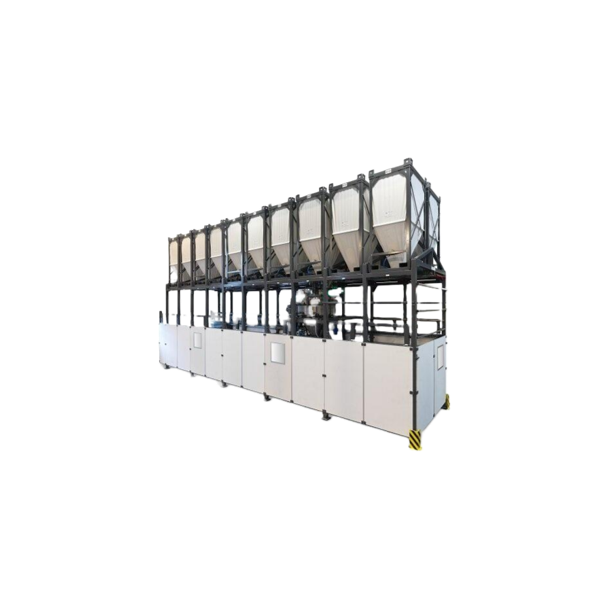

The drying of extruded products is highly energy-demanding in traditional belt dryers that use ga...

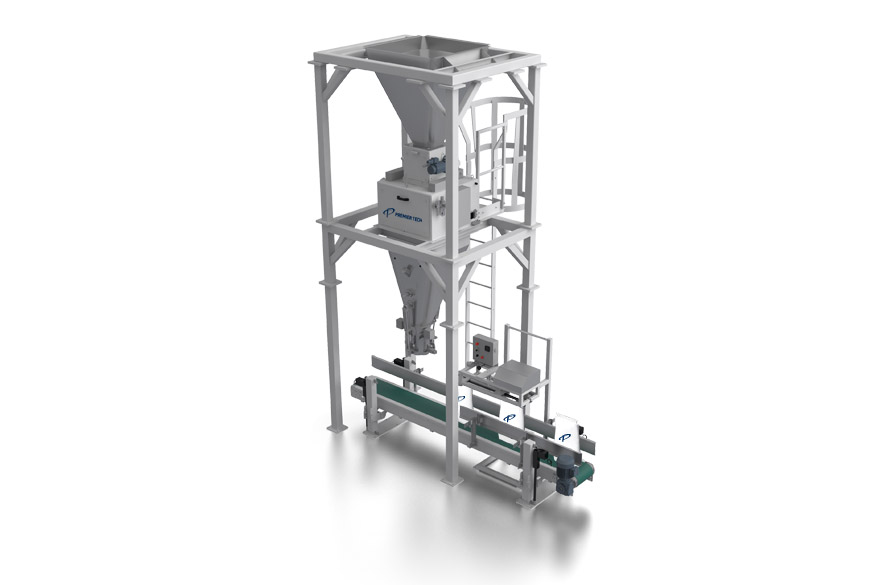

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

Box erector and bag inserter

If you are looking to improve your throughput and eliminate labor associated with manual box er...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

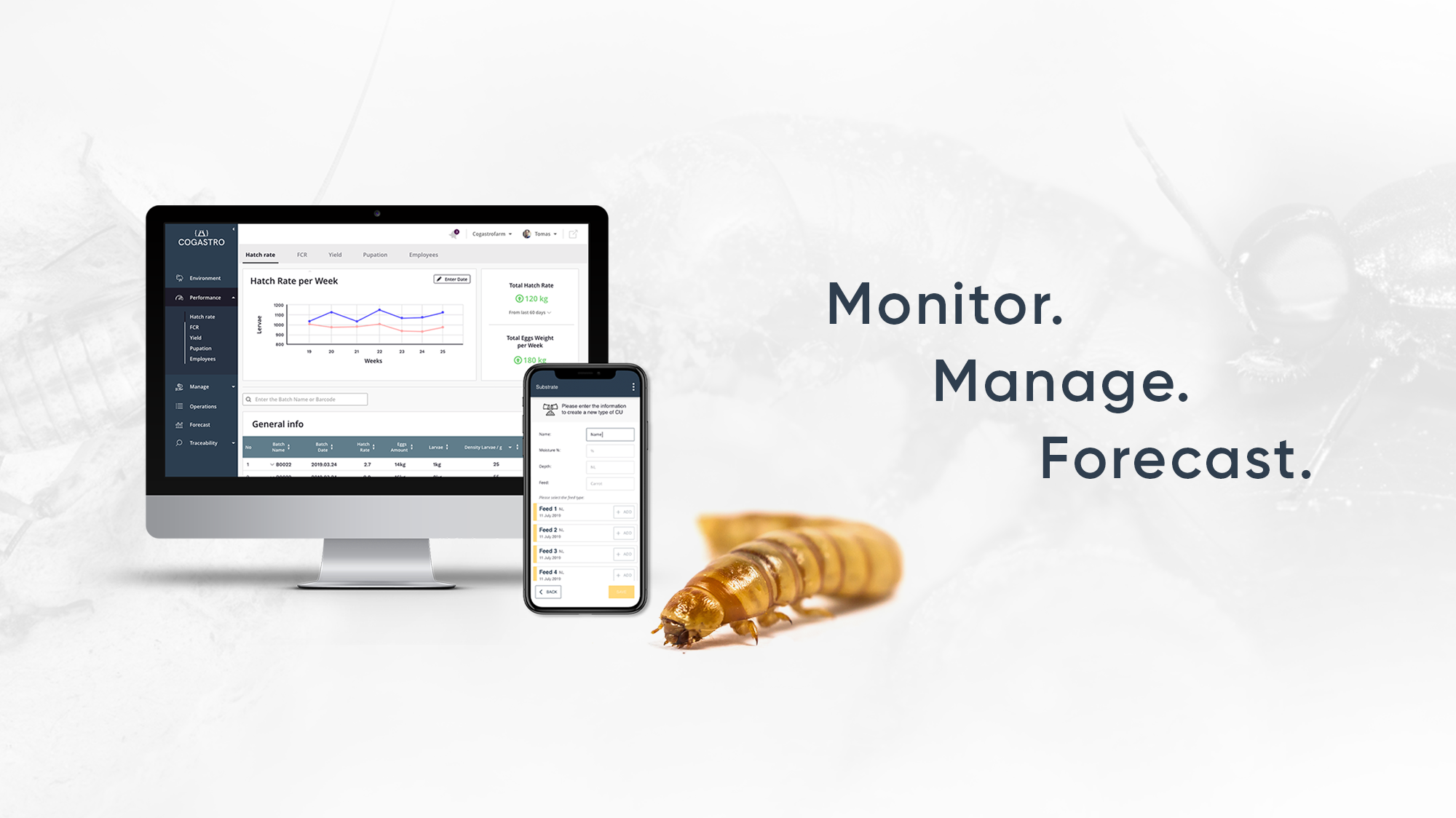

Insect farming software

No two insect farms are the same and so, each facility requires a modern and tailored solution to ope...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...