Making Whey Protein

Find innovative production technology for making whey protein and connect directly with world-leading specialists

After pasteurizing and homogenizing the raw milk, you need to ferment the milk with starter culture until solid curds and liquid whey is formed. Then, the liquid whey goes through a filtration and drying process to turn it into powder. Before sending it to packaging, flavorings are usually added.

Stories about whey protein

Tell us about your production challenge

Filtering and drying liquid whey to make powdered whey protein

Whey protein is a natural, high-quality protein found in cow’s milk. Containing all 9 essential amino acids our body needs, such as leucine or lysine, whey protein is considered a complete protein. Add a starter culture to the milk and leave it to ferment until solid curds and liquid whey form. Now you can separate the whey (watery part of the milk) from the curds by draining it from the vat.

The whey protein goes through a microfiltration process where ceramic microfilters remove fats and carbohydrates and leave liquid whey protein as a result. A hot and cold air dryer removes the moisture turns the liquid whey protein into powdered whey protein. Flavorings can be added and blend in with a mixer for uniform distribution.

Whey protein shakes, energy bars, baked goods and much more

Whey protein and its derivatives contain amino acids that promote muscle growth and aid muscle recovery. It’s consumed in drinks like protein shakes and notable for its use in muscle development and fitness. Other food varieties such as protein bars or energy bars have whey protein as an ingredient. But in other industries, like bakeries and pastries, you can use whey protein as an ingredient for emulsifying, foaming, gelling, stabilizing, and nutritional properties. And in some cases, it is used as a substitute for egg whites.

Whey protein may come as a concentrate or isolate. The concentrate is the most common type available in the market. The isolate undergoes further processing to reduce fat and lactose content, making it the preferred choice for people who are lactose intolerant.

How to pack whey protein powder?

Whey protein powder packaging is available in flexible plastic bags, hard plastic bottles, and glass bottles. The packaging or containers are properly sanitized before being filled with whey protein. A powder filling machine is used to fill containers for precision and minimum waste. Then, it is weighed to make sure the net content is the same as in the label. After filling and weighing the product, it is sealed to avoid product aeration or contamination from exposure.

Processing steps involved in whey protein making

Which whey protein technology do you need?

Separator for double cream fresh cheese

Optimize your dairy production with a high-performance centrifugal separator, desig...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

Whey concentration system with reverse osmosis

Optimize your cheese and dairy production with our reverse osmosis concentr...

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

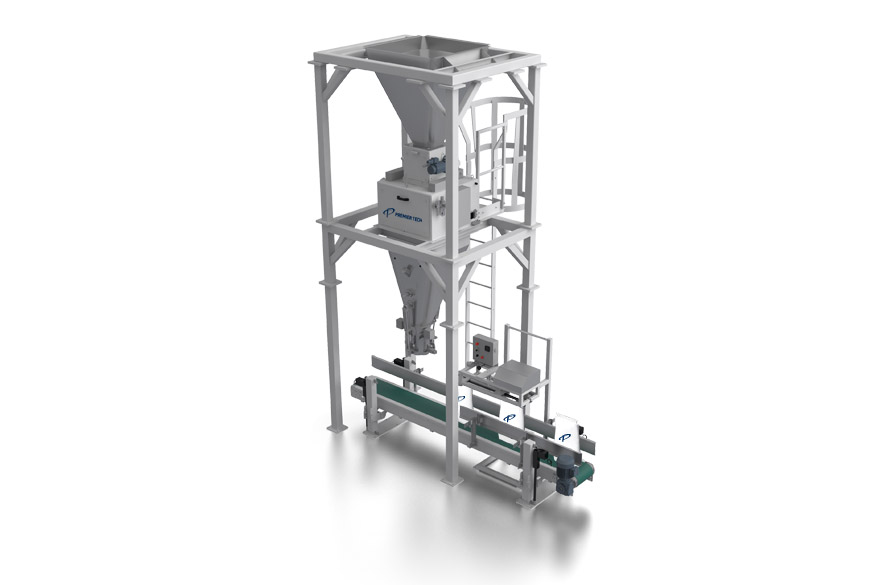

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Timing belt drying system for whey and permeate powders

Ensure high-quality production of free-flowing and non-caking whe...

Cheese vat for consistent curd size and low whey fats

Improve your cheese production with equipment designed for uniform ...

Standard batch mixer for salt and citric acid mixing

Achieve perfectly homogeneous blends of salts, sugars, and challengi...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Industrial fermentors for large-scale bioprocessing

Enhance yield and consistency in fermentation processes with precise ...

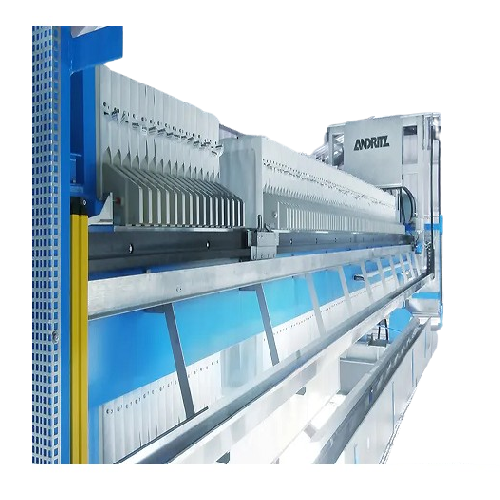

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Pressure drum filter for ultra fine-grained products

When traditional filtration methods fall short, ensure ultra-fine pr...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Ultrafiltration and microfiltration module for low to medium viscosity products

Streamline the separation and concentr...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Centrifugal pump for high-pressure systems

Designed for high-pressure systems, this centrifugal pump ensures precise filtr...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

25kg bag tipping station for powder discharge

Efficiently discharge and sieve 25kg bags of powder while minimizing dust em...

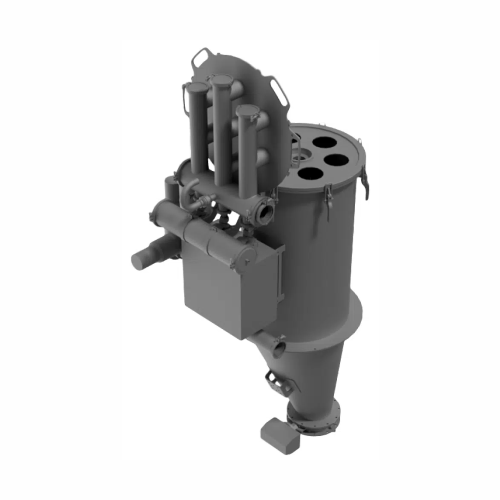

Microparticulation unit for whey protein processing

Enhance your dairy and food formulations with optimized whey protein ...

Industrial high-pressure homogenizer

Achieve precise homogenization with superior flow rates and efficiency, ensuring optim...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

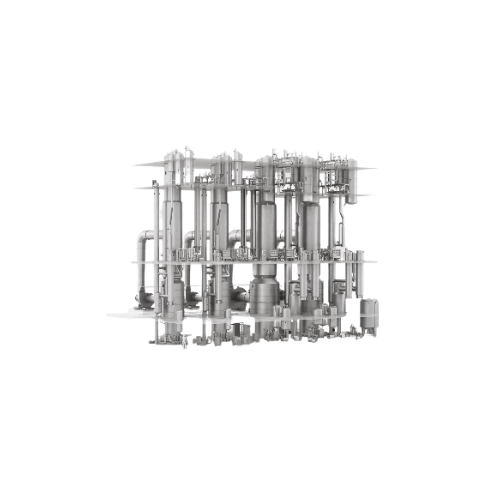

Dairy evaporator for nutritional formula

Enhance your dairy processing by optimizing energy efficiency and product quality ...

Lecithin adding system for dairy powders

Enhance your spray drying process by seamlessly integrating lecithin to improve so...

Spray dryer for whey and milk powders

Optimize your drying process for dense, agglomerated whey and milk powders with a spa...

Turnkey manufacturing and processing systems management

Streamline your production line with comprehensive assembly and c...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

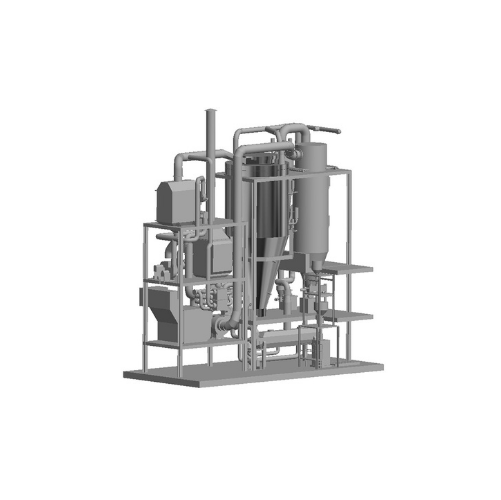

Spray drying system for heat sensitive products

For heat-sensitive products requiring precision drying, this spray drying ...

Instrumentation calibration services for accurate measurements

Ensure precise control over your production variables by ...

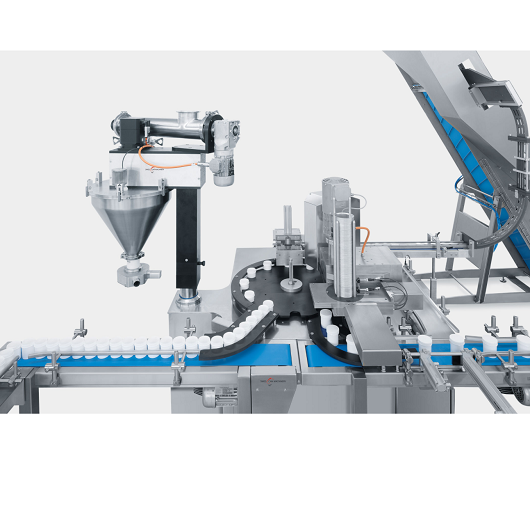

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Industrial bag filter for powder collection efficiency

For producers seeking to enhance powder yield while minimizing emi...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

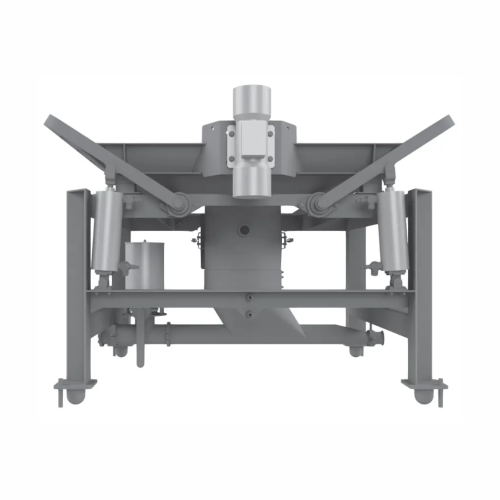

Whey tray system for cheese pressing

Optimize cheese production with an innovative system that efficiently presses semi-har...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Industrial bag filter for powder collection

Optimize powder yield and maintain strict hygiene with a high-capacity filtrat...

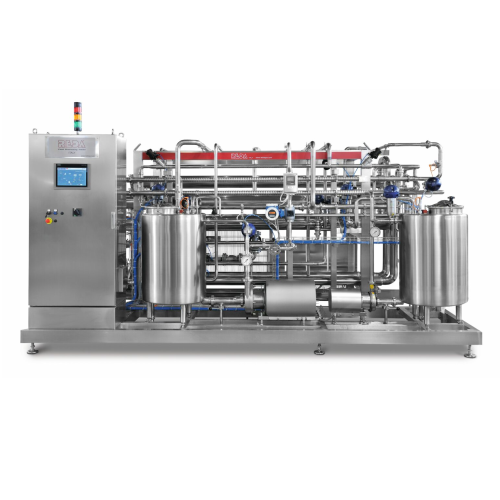

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Ultrafiltration for dairy and plant-based protein concentration

Optimize your production capacity and increase yield wit...

Falling film plate evaporators for fruit juice concentration

Achieve precise concentration of liquid products with minim...

Sanitary gasketed plate heat exchangers for clean applications

Ensure product purity and maintain hygienic standards wit...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

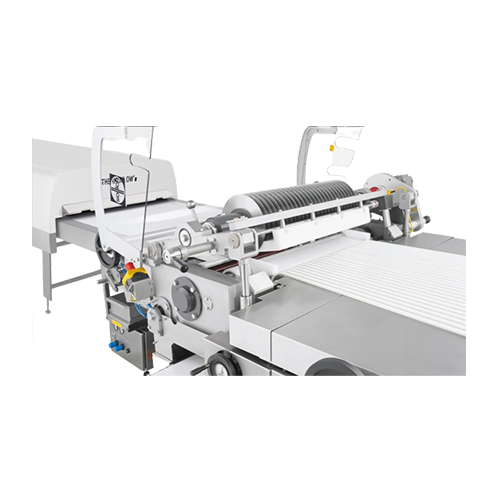

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

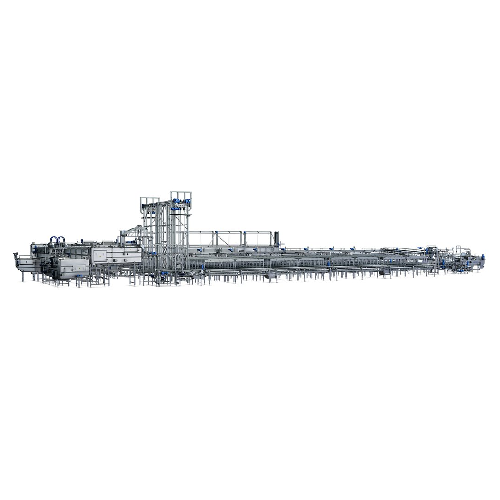

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

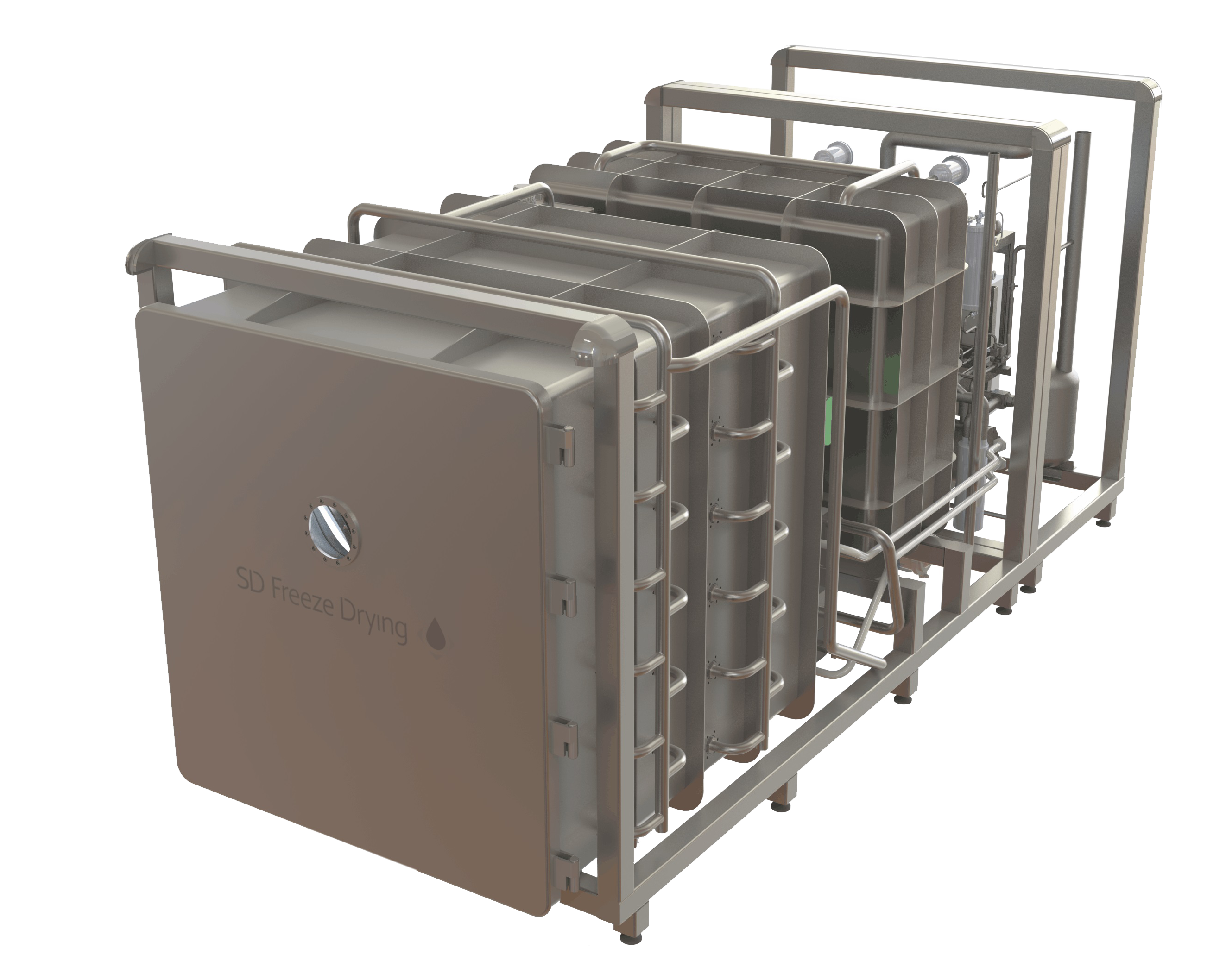

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

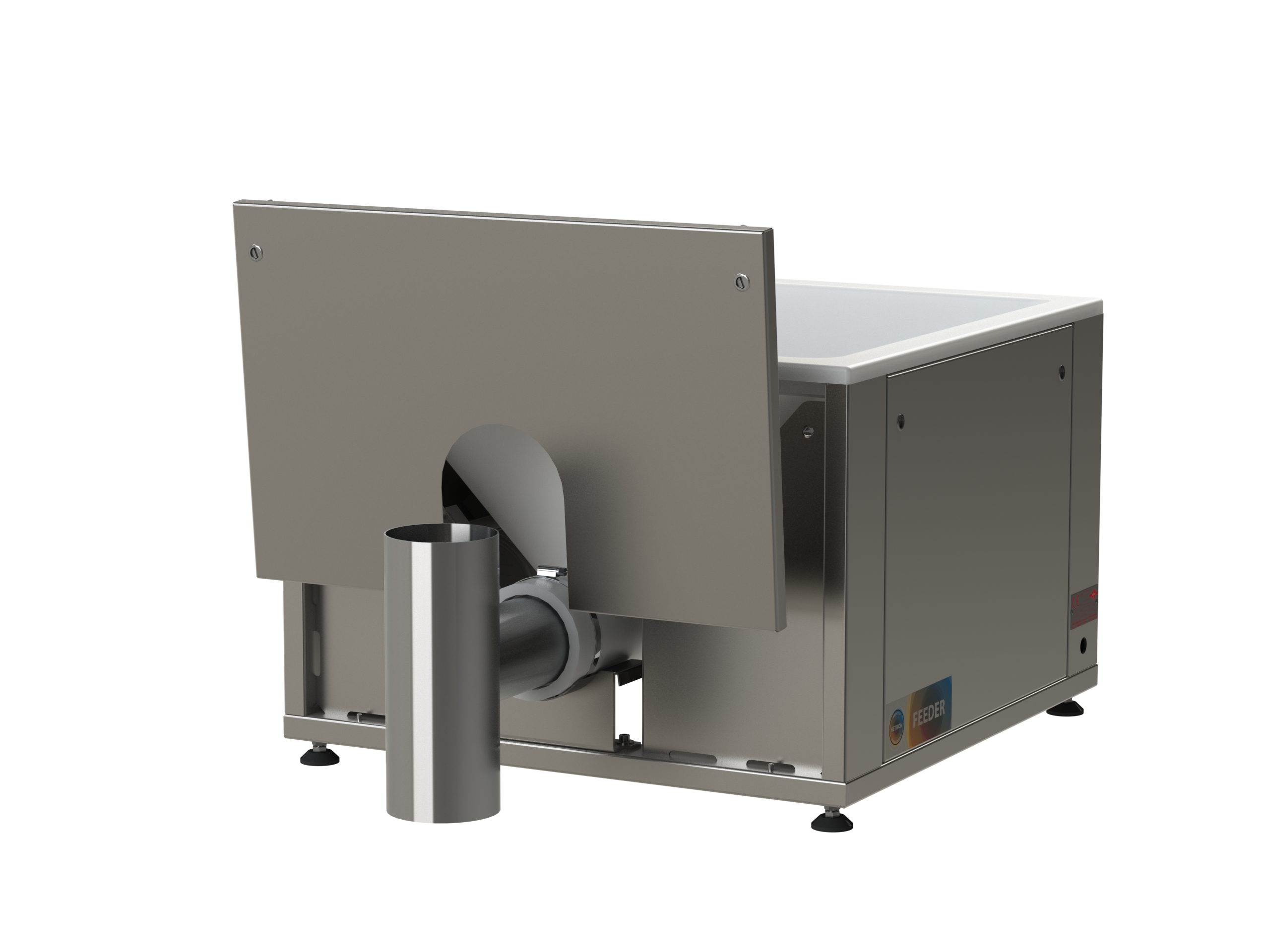

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Waterproof checkweigher

Features waterproof and dust proof cabinet and components. Its hygienic design is perfect for unpacke...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...